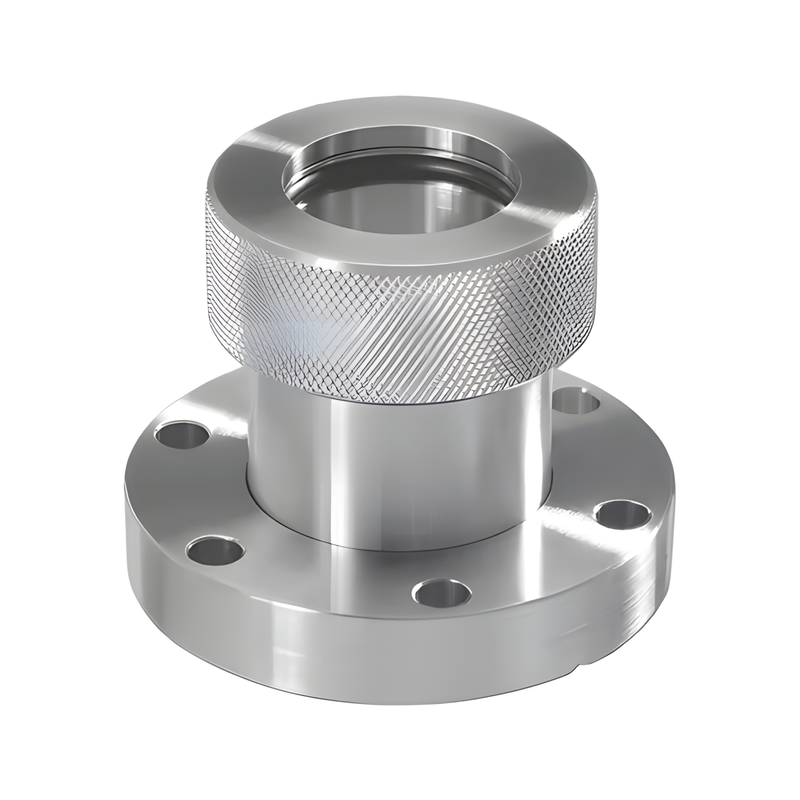

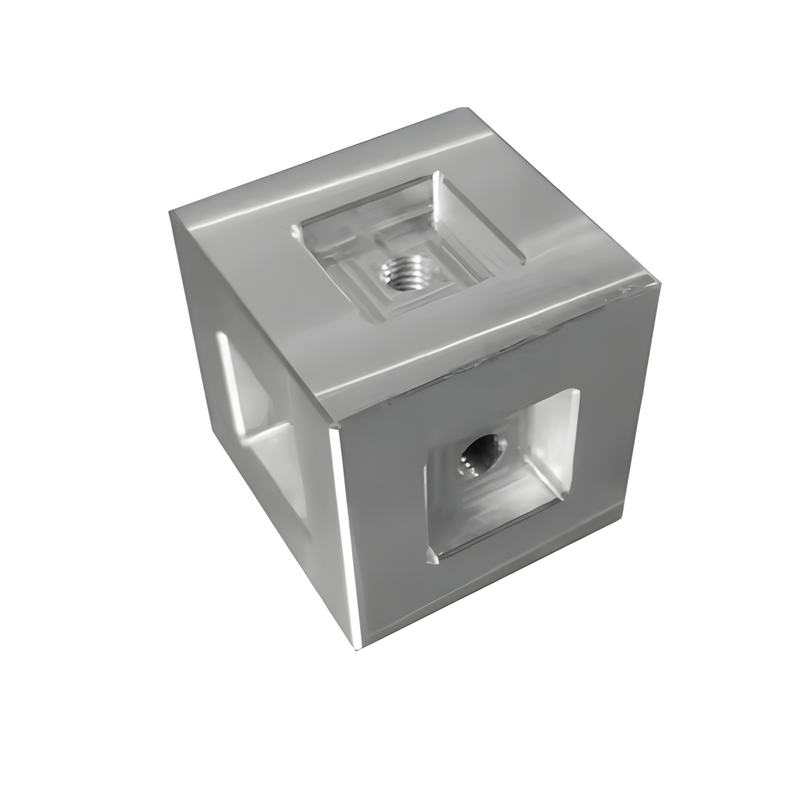

Mô tả sản phẩm

Các bộ phận CNC bằng nhôm và thép không gỉ chất lượng cao được gia công chính xác để có độ bền và độ chính xác vượt trội. Sử dụng công nghệ CNC tiên tiến, các bộ phận này được sản xuất với dung sai chặt chẽ và bề mặt hoàn thiện mịn màng. Nhôm cung cấp một lựa chọn nhẹ và chống ăn mòn, trong khi thép không gỉ mang lại sức mạnh vượt trội và khả năng chống lại môi trường khắc nghiệt. Những vật liệu này là lựa chọn lý tưởng cho các ngành công nghiệp như hàng không vũ trụ, ô tô và y tế. Gia công CNC đảm bảo kết quả đồng nhất và hiệu quả sản xuất cao. Sự linh hoạt của nhôm và thép không gỉ khiến chúng phù hợp với nhiều ứng dụng khác nhau.

Thông số sản phẩm

| Mục | Chi tiết |

| Khả năng vật liệu | Đồng thau, Nhôm, Đồng, Đồng hợp kim, Kim loại cứng, Kim loại quý, Thép không gỉ, Thép hợp kim, Khác |

| Loại | Mài |

| Mẫu | Trong vòng 7 ngày |

| Xử lý bề mặt | Anodizing, Phủ bột, Chải, Sơn, Khắc laser |

| Chứng nhận | GB/T19001-2016/ISO9001:2015 |

| Dịch vụ | Dịch vụ gia công Tiện thép không gỉ, Titan, POM, Các thành phần gia công |

| Ứng dụng | Thiết bị công nghiệp |

| Loại gia công | Dịch vụ gia công CNC nhiều trục |

Quy trình tùy chỉnh

1. Gửi yêu cầu

2. Bản vẽ hoặc mẫu

3. Báo giá

4. Xác nhận của khách hàng

5. Đặt hàng và thanh toán

6. Sản xuất hàng loạt

7. Kiểm tra trước khi đóng gói

8. Vận chuyển và xác nhận

Loại quy trình

Honing

là một quá trình gia công chính xác được sử dụng để cải thiện độ hoàn thiện bề mặt và độ chính xác kích thước của các bộ phận. Nó sử dụng một công cụ honing với đá mài quay và di chuyển qua lại trên chi tiết gia công. Thường được sử dụng cho các bề mặt hình trụ như lỗ động cơ. Honing loại bỏ một lượng nhỏ vật liệu để đạt được bề mặt mịn hơn và độ chính xác cao hơn. Quá trình này thường được áp dụng trong các ngành công nghiệp như ô tô và hàng không vũ trụ. Quá trình cũng giúp tăng độ bền và khả năng chống mài mòn của chi tiết.

Cắt laser

là một công nghệ sử dụng tia laser công suất cao để cắt qua các vật liệu như kim loại, nhựa và gỗ. Tia laser làm nóng chảy hoặc bốc hơi vật liệu theo một đường chính xác. Nó cho phép cắt với độ chính xác cao và giảm thiểu biến dạng nhiệt. Quá trình này được sử dụng trong các ngành công nghiệp như ô tô, hàng không và chế tạo. Cắt laser nhanh chóng, hiệu quả và tạo ra các cạnh cắt sạch sẽ. Nó có thể xử lý các hình dạng phức tạp và thiết kế tinh xảo một cách dễ dàng.

Mài

là một quá trình gia công sử dụng dao cắt quay để loại bỏ vật liệu khỏi chi tiết. Chi tiết được đưa vào dao cắt, dao quay với tốc độ cao để tạo hình theo các dạng mong muốn. Quá trình này có thể tạo ra nhiều tính năng khác nhau như lỗ, rãnh và các hình dạng phức tạp. Mài được sử dụng trên các vật liệu như kim loại, nhựa và gỗ. Có các loại mài khác nhau, bao gồm mài ngang và mài dọc, tùy thuộc vào cách thiết lập. Quá trình này được sử dụng rộng rãi trong các ngành công nghiệp như chế tạo, ô tô và hàng không để sản xuất các bộ phận chính xác.

Chất liệu

Sliver

Brass

Copper

Kiểm soát chất lượng

Kiểm soát chất lượng (QC) của các bộ phận CNC bằng nhôm và thép không gỉ chất lượng cao bao gồm việc kiểm tra kích thước kỹ lưỡng bằng các công cụ chính xác như thước đo micromet và máy đo tọa độ (CMM). Độ dung sai được xác minh cẩn thận để đảm bảo các bộ phận đáp ứng các thông số kỹ thuật nghiêm ngặt. Bề mặt hoàn thiện được kiểm tra để đảm bảo độ mịn màng và sự đồng nhất. Tính toàn vẹn của vật liệu được kiểm tra để đảm bảo độ bền và khả năng chống ăn mòn. Việc hiệu chuẩn công cụ được thực hiện thường xuyên để duy trì độ chính xác trong gia công. Các sản phẩm cuối cùng được kiểm tra chức năng để đảm bảo chúng đáp ứng các tiêu chuẩn hiệu suất trước khi giao hàng.

Khả năng xử lý

Khả năng gia công của các bộ phận CNC bằng nhôm và thép không gỉ chất lượng cao bao gồm gia công chính xác với dung sai chặt chẽ và các hình học phức tạp. Công nghệ CNC cho phép phay, tiện và khoan chính xác các bộ phận nhôm và thép không gỉ. Những vật liệu này có thể được tạo hình thành các bộ phận nhẹ, chống ăn mòn hoặc có độ bền cao. Máy CNC đa trục cho phép thực hiện các kỹ thuật cắt nâng cao cho các thiết kế phức tạp. Sự linh hoạt của gia công CNC đảm bảo hiệu quả sản xuất cao và chất lượng đồng đều giữa các lô sản xuất. Những vật liệu này là lựa chọn lý tưởng cho các ngành công nghiệp yêu cầu các bộ phận chính xác, có độ bền cao, chẳng hạn như hàng không vũ trụ và ô tô.