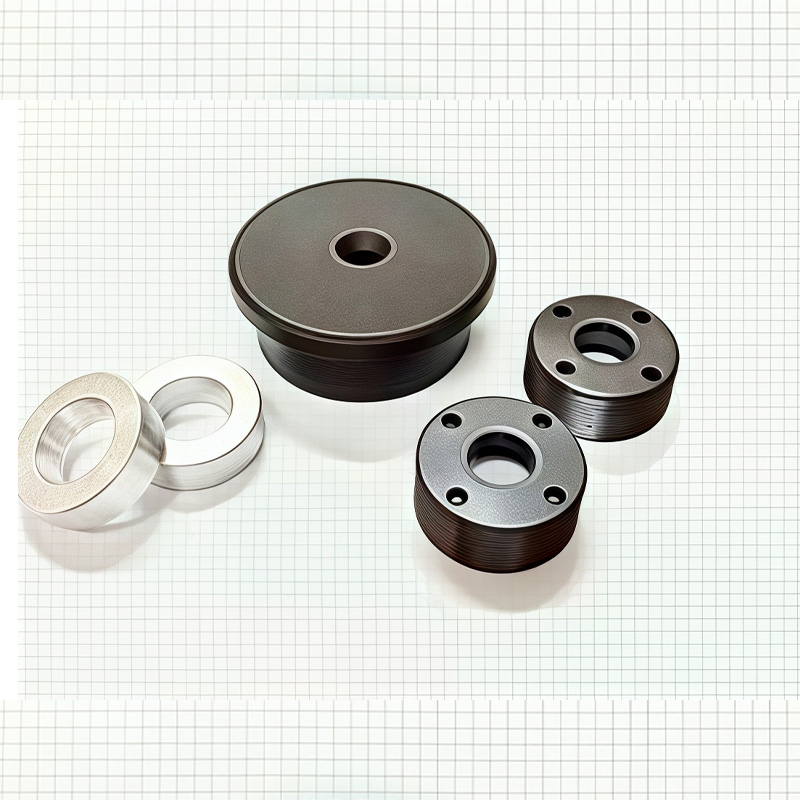

Product Description

We specialize in non-standard customized production and processing of metal accessories. We have advanced equipment and professional teams. From drawing design to finished product delivery, we strictly control the whole process to accurately meet your personalized needs and help various industrial projects to advance efficiently.

Product parameters

Material | Steel or Carbide |

Accuracy | Depends on drawing details. |

Delivery Time | 14 days |

Urgent Delivery | 7 days |

Color | Silver |

Size | Customized |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

Process Type

Material

Brass

Steel

Steeless

Aluminum

Quality Control

Concentricity-Gage

The concentricity measuring instrument is an important tool for product quality control. It focuses on accurately measuring the concentricity of rotating parts with extremely high precision. In the field of automobile manufacturing, it is used to detect engine crankshafts, wheel hubs and other components to ensure the concentric assembly of each component to avoid vibration and wear during operation. In motor production, it can accurately measure the concentricity of the rotor and stator to ensure efficient and smooth operation of the motor. It provides key data for many industries and effectively helps companies strictly control product quality.

Gear tester

Gear tester is crucial in product quality control. It can measure various parameters of gears, such as tooth shape, tooth direction, and tooth pitch, with high precision. In the mechanical equipment manufacturing industry, it is used to accurately detect gears to ensure their meshing accuracy and avoid noise, jamming and excessive wear during the transmission process. In the production of automobile transmissions, it is the core equipment to ensure the quality of gears, lay the foundation for creating a smooth shifting experience, and help companies produce products that meet standards and have reliable performance.

Dial-Indicator

As a precision measuring instrument, the micrometer plays a key role in product quality control. It can accurately measure tiny dimensional changes with an accuracy of up to 0.001mm. In mechanical processing, the micrometer is used to detect the flatness and cylindricity of parts, so as to timely discover processing deviations and adjust process parameters to ensure that the product meets the design requirements. In precision manufacturing fields such as electronics and aviation, the micrometer is also a powerful assistant in controlling quality and provides reliable data support for the production of high-precision products.

Processing capability

Material material composition analysis machine

Raw materials are the most important part of products. When one millionth error cannot be tolerated, spectral inspection must be done before the raw materials enter the warehouse to ensure that the raw material are the same every time.

CNC GRINDING MACHINE

Wide variation is selectable according to diversified workpieces.

OD: 355mm max, width: 50mm max. High efficient grinding realized by high rigid dynamic bearing.

Automation is easy by optional accessories, such as loader, stocker, etc.

SB type: OD grinding, mas production straight type (NC simultaneous2-axis)

AB type: OD and end face simultaneous grinding mass production angular type (NC simultaneous 2-axis)

Additional processes

Surface plating treatment

Electroplating is widely used in the production and processing of mechanical parts. it can be used to plate wear-resistant coatings on parts, such as electroplating chrome on the surface of gears, to enhance their wear resistance and extend their service life. anti-corrosion coatings such as zinc plating can effectively protect nuts, bolts, etc. from rusting in humid environments. In addition, some appearance parts can be electroplated to obtain a bright and beautiful surface.