Huraian Produk

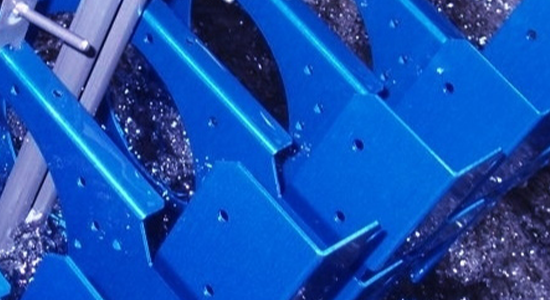

Dalam bidang pemesinan ketepatan bukan standard, kami adalah pengilang pemesinan CNC ketepatan tersuai profesional. Untuk bahan yang berbeza seperti aluminium, loyang, keluli, dsb., kami menggunakan teknologi pengilangan dan pemusing CNC, bergantung pada peralatan CNC berketepatan tinggi, dan mengawal ketat keseluruhan proses daripada pemilihan bahan mentah kepada pemeriksaan produk siap untuk mencipta bahagian mesin CNC berkualiti tinggi untuk anda.

Parameter produk

Model | Mengikut lukisan |

Rawatan permukaan | Keperluan pelanggan |

Saiz | Saiz tersuai boleh diterima |

Perkhidmatan | OEM tersuai |

Permohonan | Peralatan industri |

Proses Suai

1.Komunikasi keperluan

2.Reka bentuk lukisan

3.Perolehan bahan

4.Pemprosesan dan Pembuatan

5.Rawatan permukaan

6.Perhimpunan dan penyahpepijatan

7.Pemeriksaan dan pembungkusan

8.Penghantaran dan Selepas jualan

Material

Keluli Karbon

Titanium

Aloi Tembaga

Aloi Aluminium

Kawalan Kualiti

Sebagai pakar dalam pemesinan ketepatan, kami mematuhi sepenuhnya kawalan kualiti. Daripada penyimpanan bahan mentah berkualiti tinggi, kepada pelbagai proses dalam pemprosesan, kepada pemeriksaan menyeluruh produk siap, kami tidak akan terlepas sebarang kecacatan, dan menggunakan piawaian yang ketat untuk mencipta produk yang diproses berkualiti tinggi, dan menggunakan kekuatan untuk mentafsirkan pematuhan kepada kualiti.

Kemampuan proses

Di Microvit, kami menggabungkan teknologi canggih dan kepakaran pengaturcaraan CNC yang berpengalaman untuk menyediakan pemesinan CNC perkhidmatan penuh untuk pengeluaran High-Mix Low-Volume bagi komponen dan bahagian logam tiga dimensi yang kompleks. Dengan lebih daripada 35 pusat pemesinan CNC dan operasi siang dan malam, kami boleh menghasilkan komponen yang dimesin dengan pantas dan berkesan, dengan kualiti yang luar biasa dan kebolehulangan yang tinggi dari bahagian pertama hingga yang terakhir.

Proses tambahan

Proses penyaduran elektrik

Penyaduran elektro ialah satu proses mendepositkan lapisan logam atau aloi pada permukaan logam atau bahan lain dengan kaedah elektrokimia. Prinsipnya ialah menggunakan bahan kerja untuk disadur sebagai katod dalam larutan yang mengandungi ion logam, dan menggunakan arus terus untuk mengurangkan dan mendepositkan ion logam pada permukaan bahan kerja untuk membentuk salutan yang seragam dan padat.