Product Description

Professional nickel plating

for custom parts

Customized thickness available

High hardness and strong adhesion

Corrosion and wear resistance

Guaranteed precision

Functional Features

Process Features

(For non-standard parts)

Excellent plating uniformity

This solves the traditional electroplating problem of thick edges and thin interiors on special-shaped parts, achieving consistent plating thickness on blind holes, grooves, and threads.

Comprehensive Performance

The corrosion resistance and wear resistance of the coating are better than those of ordinary electroplated nickel, and it has a certain conductivity, which can meet the multifunctional needs of non-standard parts.

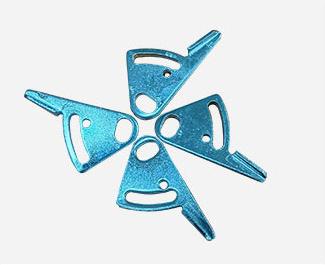

Product Display

Nickel plating product display

Barrel nickel plating |

Environmentally friendly bright nickel |

Nickel plating |

Nickel plating |

Black nickel plating |

Black nickel plating |

Application

Application Areas

Mechanical manufacturing field

automotive industry

Electronic and electrical field

Medical device field

Aerospace

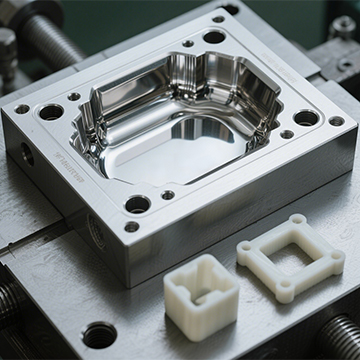

Mold manufacturing field

Model Description

Types of electroplating nickel plating processes

Types of crafts | Process characteristics | Applicable materials | The main benefits of nickel plating |

Ordinary nickel plating | Silvery white, matte, fine crystals, no brightener, low internal stress | Metal substrates such as steel, copper and copper alloys, aluminum and aluminum alloys (need zinc pretreatment), and magnesium alloys | Suitable for basic protection of structural parts. |

Bright Nickel Plating | Contains organic brighteners (such as saccharin, butynediol), the coating has a mirror-like luster and does not require subsequent polishing | Steel, copper alloy, zinc alloy (needs pre-plating or passivation), plastic (after chemical plating pre-treatment) | The corrosion resistance is better than dark nickel, suitable for decorative parts (such as bathroom hardware, electronic product housing) |

High Stress Nickel Plating | High internal stress, extremely high hardness (300-500HV), excellent wear resistance, but poor ductility | Mainly suitable for steel substrates (such as tools, molds, bearings) | Significantly improve surface wear resistance and extend the service life of moving parts (gears, mold edges) |

Low Stress Nickel Plating | Contains stress relief agent, low internal stress, good ductility, suitable for thick coating deposition | Steel, copper alloy, etc., especially suitable for substrates requiring thick coatings (such as repair of worn parts) | The coating is not easy to crack and is suitable for parts that need to be bent or deformed |

Chemical Nickel Plating | No external power supply is required, nickel-phosphorus alloy is deposited through chemical reaction, and the coating uniformity is excellent (suitable for complex shapes) | Metals (steel, copper, aluminum, etc.), non-metals (plastics, ceramics, glass, etc., which require activation pretreatment) | Excellent corrosion resistance and wear resistance, suitable for chemical equipment and seals; |

Satin Nickel Plating | Matt or satin appearance, no mirror gloss, soft texture, contains special matte additives | Steel, copper alloy, etc., especially suitable for substrates requiring thick coatings (such as repair of worn parts) | Enhance the quality of high-end decorative parts (luxury accessories, instrument panels); avoid mirror reflections and are suitable for light-sensitive scenes. |

Black Nickel Plating | Black appearance, composed of compounds of nickel, sulfur, selenium and other elements, has both decorative and matte properties | Steel, copper alloy, zinc alloy (need to be pre-nickel plated) | Used in functional scenarios such as optical instruments (matte), weapon parts (camouflage), etc. |

Product parameters

Electroplating nickel plating parameter table

Parameter Category | Specific parameters | Standard requirements | Detection method |

Staining agent components | Nickel sulfate (NiSO₄・6H₂O) concentration (Watt nickel plating solution) | 240 - 300g/L | Titration / ICP-OES (GB/T 3914) |

Nickel chloride (NiCl₂・6H₂O) concentration (Watt nickel plating solution) | 30 - 60g/L | Titration / ICP-OES (GB/T 3914) | |

Boric acid (H₃BO₃) concentration (Watt nickel plating solution) | 30 - 40g/L | Titration / ICP-OES (GB/T 3914) | |

Nickel sulfamate (Ni (NH₂SO₃)₂) concentration (nickel sulfamate plating solution) | 300 - 450g/L | Titration / ICP-OES (GB/T 3914) | |

Nickel chloride (NiCl₂・6H₂O) concentration (nickel sulfamate plating solution) | 0 - 15g/L | Titration / ICP-OES (GB/T 3914) | |

pH value (Watts nickel plating bath) | 3.0 - 4.5 | Acidity meter (GB/T 9724) | |

pH value (nickel sulfamate plating solution) | 3.5 - 4.5 | Acidity meter (GB/T 9724) | |

Chloride ion (Cl⁻) content | ≤0.1g/L | Silver nitrate titration (GB/T 11896) | |

Additive content (such as brightener) | 0.5 - 2mL/L(按供应商标准) | High-performance liquid chromatography (HPLC, ASTM E1657) | |

Physical parameters of plating solution | Conductivity | 40 - 60mS/cm(25℃) | Conductivity meter (GB/T 11007) |

Density | There is no clear unified standard for nickel plating. It usually varies according to the composition of the plating solution. You can refer to the standard of chrome plating solution, which is about 1.15-1.30g/cm³. | Density meter (GB/T 4472) | |

Temperature stability | Working temperature fluctuation ≤±2℃ | Constant temperature bath simulation (GB/T 5170) | |

Metal impurity (Fe) content | ≤50ppm | ICP - MS(GB/T 23947) | |

Process conditions | Temperature (Watt Nickel Plating Solution) | 45 - 60°C | Thermometer measurement |

Temperature (Sulfamate Nickel Plating Solution) | 40 - 60°C | Thermometer measurement | |

Current Density (Watt Nickel Plating Solution) | 2 - 10A/dm² (typically 3 - 5A/dm²) | Amperemeter measurement | |

Current Density (Sulfamate Nickel Plating Solution) | 5 - 20A/dm² (high-speed plating) | Amperemeter measurement | |

Stirring Method | Air or mechanical agitation | Visually observe the operation of the mixing equipment | |

Coating performance | Coating thickness | ≥5μm | X-ray fluorescence thickness gauge (GB/T 6463) |

Porosity | ≤5 pieces/cm² (anti-corrosion coating) | Nitric acid vapor method (ISO 14647) | |

Adhesion | No peeling, no cracks (thermal shock test 300℃↔room temperature, according to GB/T 5270 | Thermal shock test device | |

Corrosion resistance | Nickel coating passes 96h neutral salt spray test, white rust area ≤5%, no red rust (ASTM B117) | Neutral salt spray test chamber (ASTM B117) | |

Quality Control

Testing equipment

2.5Dimension |

elemental analyzer |

CCD automatic testing machine |

Roughness Tester |

Gloss meter |

resistance meter |

Salt spray test machine |

Film thickness meter |

Voltmeter |

Color matching light box |

Pencil Hardness Tester |

Metallographic microscope |

Company Showcase

Factory Service Highlights

We have a professional chemical nickel plating workshop that can process large non-standard parts with a maximum size of 2m×1m×0.8m and micro non-standard parts with a minimum size of 0.5mm.

The factory has its own laboratory, which can optimize the plating solution formula according to the use environment of non-standard parts (such as high temperature, high humidity, acid and alkaline media).

Applicable non-standard parts: aerospace special-shaped connectors, petroleum machinery deep hole components, electronic communication precision non-standard parts, chemical equipment corrosion-resistant accessories, etc.

We are a physical factory specializing in surface treatment of non-standard parts

With over 20 sets of professional electroplating equipment and a 15-person technical team, we offer a comprehensive service process, from process selection and sample testing to mass production, tailored to your specific part material (metal/some engineering plastics), application scenario, and performance requirements. We support processing based on supplied samples and custom drawings, rejecting the compromises of "standardized production" to ensure each custom part receives a precisely tailored surface treatment.