Product Description

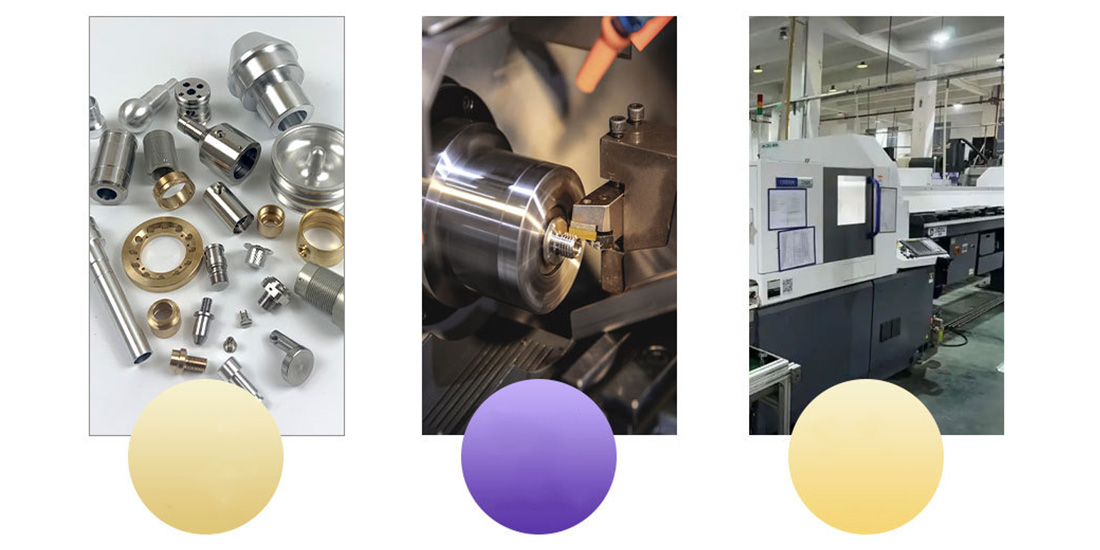

5-Axis Metal Machining

Factory Supply / Customization Supported

Precision Manufacturing

Reliable Quality Sufficient Supply Quality Inspection

Functional Features

01

Precision at Heart, Simplicity in Form

With micron-level precision, we ensure every detail is perfect,

helping your product stand out from the rest.

02

Efficiency Meets Quality

Whether it's complex mechanical structures or delicate electronic components,

we handle it with ease—delivering exceptional quality.

03

Innovation Driven, Quality Built

We continuously push the boundaries of technology, combining advanced manufacturing processes

with strict quality control to create reliable hardware components for you.

04

Professional Service, Worry-Free Experience

From design consultation to after-sales support, we offer end-to-end service

to ensure your every need is met with timely and professional response.

Product Display

Direct-from-Factory Quality Assurance Genuine Materials

Application

Exquisite Workmanship with Precision Machining

Product parameters

Parameter | Specification | Parameter | Specification |

Product Name | Customizable Non-Standard | Product Precision | Precision Machining |

Minimum Machining Size | Customizable Non-Standard | Prototype Lead Time | 3–5 Days |

Processable Materials | Various Metals / Non-Metals | Feature | High-precision parts with 0.01mm parallelism |

Custom Machining

Focused on Crafting High-Quality Precision Products

Customer satisfaction is everything to us.

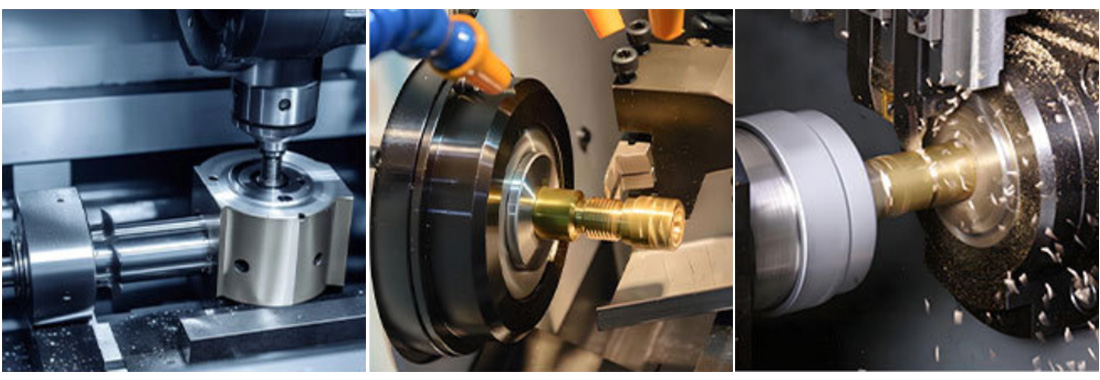

Hardware Design-Based CNC Machining

Machining Types

Supported Machining Services

Quality Assurance & Fine Workmanship

| CNC Machining | CNC Lathe | Turning-Milling Compound Machining |

Custom Process

Contact Customer Service

Provide Documents

Quotation Calculation

Confirm Plan

Pay Deposit and Place Order

Processing and Manufacturing

Packaging and Shipping

After-Sales Service

Quality Control

Professional Testing Equipment

Quality Assurance

Service

Mechanical Parts of Various Materials

Quality Service Nonstop

| Customization Based on Provided Drawings: CAD Format, PDF, STP, PRT, IGS |

| Wide Range of Materials Available: Aluminum, Copper, Stainless Steel, Carbon Steel, POM, etc. |

| Our Firm Commitment: We offer free repairs for any quality issues caused by machining. |

FAQ

Detailed Communication?

Before customization, communicate thoroughly with the supplier to clarify specific requirements of the parts, including material, dimensions, shape, precision, surface treatment, etc., to avoid product mismatch due to unclear demands.

Product Issues?

All products are customized. Please contact customer service before placing an order. Customized products are made based on the customer's personalized needs and are unique, usually non-resalable. Therefore, returns or refunds are not supported after ordering. Thank you for your understanding! If there are quality issues with the customized product, customers have the right to request repair or replacement from the seller.

Problem Handling?

If any issues are found during inspection, contact the supplier promptly and discuss solutions such as rework or repair to ensure the problem is properly addressed.