Product Description

Focusing on CNC machining for more than 20 years

Mainly engaged in design, processing and sales of non-standard mechanical parts

Our team members are composed of engineers and executives with many years of foreign-funded factory background. The equipment is complete and stable. We undertake one-stop online processing services such as CNC gongs, CNC lathes and milling machines, Core moving machine, stamping and welding. Products include engine parts, automation parts, sensor parts, medical equipment parts, communication housings and other legal non-standard parts.

Our Advantages

| Six advantages of our products | ||

01

Optimal Price We have physical factory, and the bulk purchase price is more favorable. | 02

High Efficiency The team's engineers have more than 20 years of processing experience, faster efficiency and more assured. | 03

High Quality Full inspection required before shipment, customer satisfaction is 100%, and quality is guaranteed. |

04

After-Sales Professional account managers can provide one-to-one service to solve your worries. | 05

Factory Proprietary We sell directly from the factory, and the bulk purchase price is more favorable. | 06

Fast Delivery Short production time, 90% of the time will be shipped in advance. |

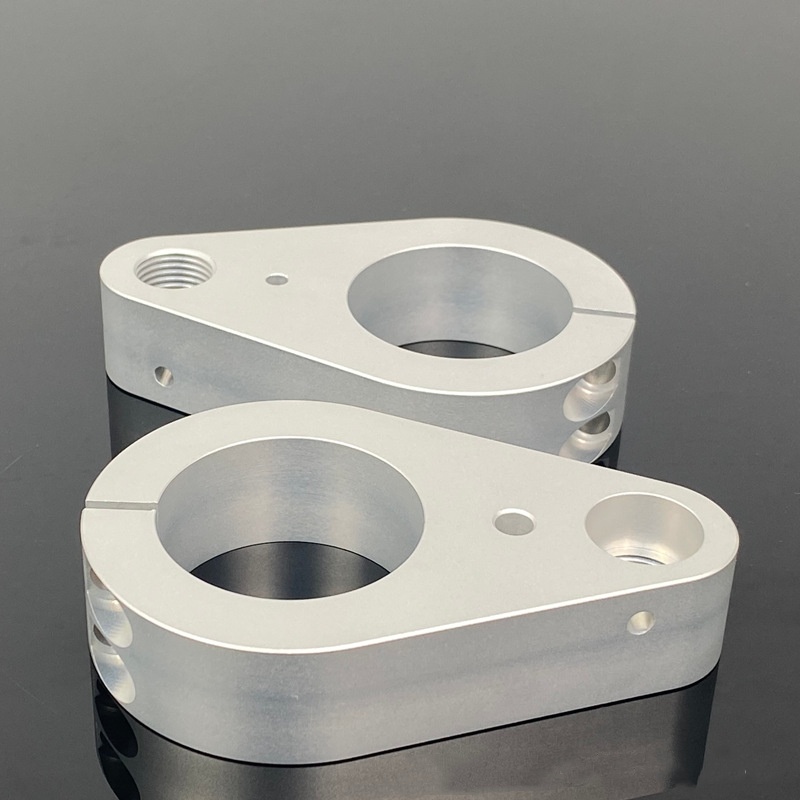

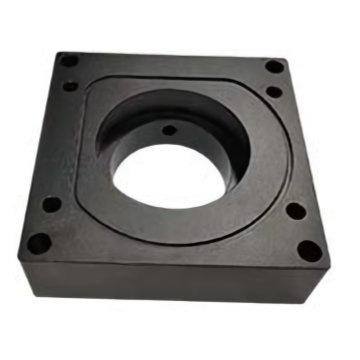

Product Display

Mechanical Processing Case Display

Product parameters

Machining Type | Turning | Processing accuracy | Finishing |

Turning type | CNC lathe | Processing materials | Stainless steel、Brass、Aluminum alloy |

Maximum diameter | 850 (mm) | Maximum length | 500 (mm) |

Tolerance | 0.01mm | Surface roughness | 0.01 |

Lead time | 1-3 workdays | Processing time | 4-7 workdays |

Annual remaining processing capacity | 1,000,000 (items) | Annual maximum processing capacity | 1,000,000 (items) |

Custom Process

Customization at our factory takes only three quick steps

1. Send Drawings

Via Email or Online

2. Quote Feedback

By Engineering

3. Confirm & Pay

Customer service

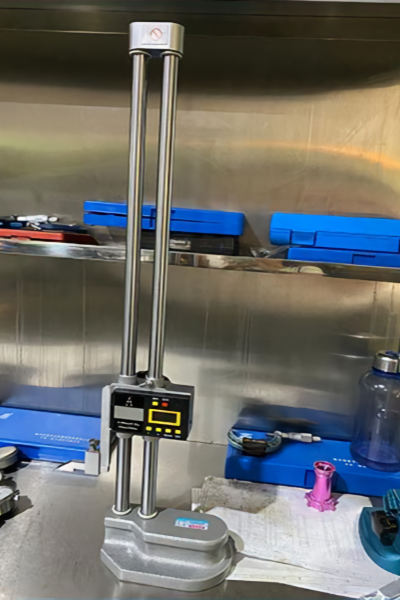

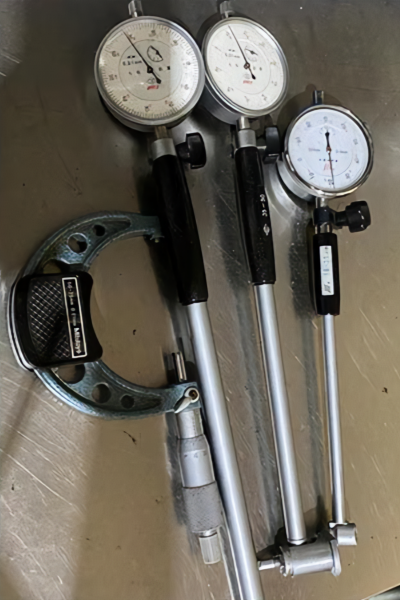

Equipment List

Precision machining equipment

Service

Quality Commitment

We promise: If a part cannot be used due to processing problems, we will be responsible for free repair or reprocessing.

Processing Instructions

About drawings:

CAD format: DWG, DXF/PDF

3D format: SIDPRT, STEP, IGS, STP, XT, PRT

About materials:

Metals: stainless steel, aluminum alloy, copper, 45# steel, iron, etc.

Non-metals: nylon, bakelite, acrylic, POM, PP, ABS, etc.

About precision:

Our company promises that the precision can be guaranteed to achieve a minimum tolerance of 0.01mm, but it is usually processed according to the requirements of the drawings

About processing:

Sandblasting, anodizing, brushing, blackening, chrome plating, galvanizing, gold plating, silk screen, laser (laser marking), spraying Teflon, spray painting, etc.

Packaging Information

| Length(cm) | Width(cm) | Height(cm) | Volume (cm³ | Weight(g) |

| 20 | 20 | 20 | 8000 | 1000 |

Purchase Notice

Purchase Notice

1、Our company specializes in non-standard customization, processing according to drawings and samples, no stock, please be advised!

2、The prices of all products in this store are not the actual prices of the products. Please consult the customer for quotation verification before placing an order. Orders placed without contact will be deemed invalid orders and will not be shipped. Please be aware of this and thank you for your cooperation.

3、If the customer does not respond to you in time, you can leave a message with your email and phone number and we will contact you later, or you can call us.

4、If it is not customized according to the customer's drawings, we will replace it for free and bear the domestic round-trip freight.

5、Quickly make samples in 3 days, and the minimum batch trial production can be 5 days, with fast delivery.

6、Customize strictly according to the dimensions on the drawings. If there are tolerance problems, we will replace it free of charge.