Product Description

Quality control for Customized CNC Machining Steel ensures that each part meets precise specifications and high industry standards. Utilizing state-of-the-art measurement equipment and experienced technicians, we perform comprehensive inspections at every stage of production. From initial design validation to final part testing, we ensure dimensional accuracy, surface finish consistency, and material integrity.

Product parameters

The minimum order quantity | 1 piece |

Color/size | habits |

Tolerance | 0.001 mm -0.05 mm |

Micromachining or not | Micromachining |

Model | OEM OEM |

Product name | CNC machining aluminum parts |

Service | CNC machining/milling/turning etc. |

Quality | 100% based on production drawings or samples |

Drawing format | 2D/ (PDF/CAD) 3D (IGES/STEP)/as sample |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

7.Test before packaging

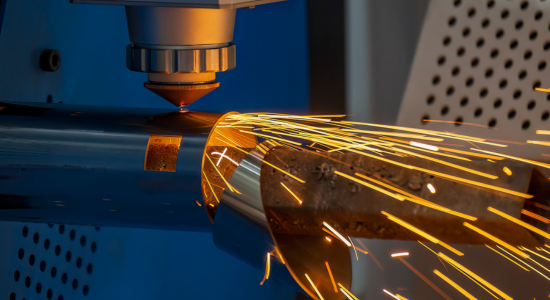

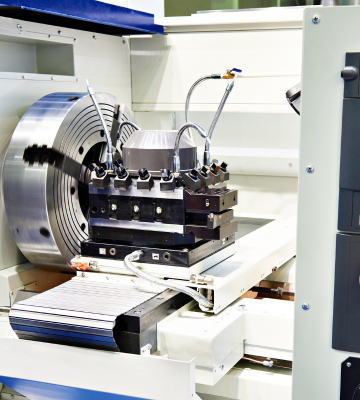

Process Type

CNC Turning

Used to manufacture cylindrical steel components, such as shafts, bushings, and connectors, with high precision for applications requiring smooth surfaces and tight tolerances.

CNC Milling

Ideal for creating complex, multi-dimensional parts, such as gears, brackets, and housings, which require detailed cutting, drilling, and shaping on flat or irregular surfaces.

CNC Lathe Operations

Applied to produce parts that require precise internal or external threading, grooves, or other intricate shapes, such as valves, fittings, and pipe components, especially for high-stress environments like marine applications.

Material

Stainless Steel

Copper

Aluminum Alloy

Quality Control

Processing capability

Additional processes