คำอธิบายผลิตภัณฑ์

การประมวลผลแบบกำหนดเองที่ไม่เป็นมาตรฐานอย่างแม่นยำ

รองรับการปรับแต่งที่ไม่เป็นมาตรฐาน/การผลิตตัวอย่างอย่างรวดเร็ว/ทนทาน

ขอบเขตธุรกิจ

ขอบเขตธุรกิจ

1. การแปรรูปผลิตภัณฑ์:

การประมวลผลเพลา, ชิ้นส่วนส่งกำลังแบบสกรูและเฟืองตัวหนอน, ข้อต่อลูเออร์, อุปกรณ์วาล์ว, อุปกรณ์ทางทันตกรรมออร์โธปิดิกส์

2. ขั้นตอนการดำเนินการ:

เราให้บริการครบวงจร เช่น การกลึง การกัด การเจาะ การต๊าป การกลึง การทำให้แบน การเจียร และการชุบด้วยไฟฟ้า

3. อุปกรณ์การประมวลผล:

เครื่องกลึงแบบสตาร์สวิส เครื่องเจาะและต๊าปความเร็วสูง

4. การบำบัดพื้นผิว:

การออกซิเดชั่น การชุบด้วยไฟฟ้า (การชุบทอง การชุบเงิน การชุบดีบุก การชุบสังกะสี (สังกะสีขาว สังกะสีสี) การชุบโครเมียม การชุบนิกเกิล) การชุบแข็งและการชุบแข็ง

5. หมายเหตุ:

มีความเชี่ยวชาญด้านการผลิตชิ้นส่วนมาตรฐานและชิ้นส่วนโลหะที่ไม่เป็นมาตรฐานต่างๆ ครอบคลุมถึงฮาร์ดแวร์อุปกรณ์ตกปลา ฮาร์ดแวร์ไฟฟ้า ฮาร์ดแวร์อิเล็กทรอนิกส์ ฮาร์ดแวร์อุปกรณ์ทางการแพทย์ ฮาร์ดแวร์เครื่องมือวัด ฮาร์ดแวร์ยานยนต์ การผลิตวิศวกรรมการบินและกองทัพเรือ และสาขาอื่นๆ มีสินค้าหลากหลายนับพันรายการให้ลูกค้าเลือก

ประเภทการประมวลผล

Processing Type

ฟันเล็บและเล็บกระดูก |

ขั้วต่อลูเออร์ |

ชิ้นส่วนเพลา |

อุปกรณ์วาล์ว |

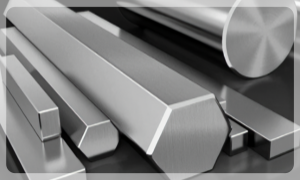

วัสดุ

เราสามารถดำเนินการวัสดุได้ หากคุณมีความต้องการอื่น ๆ โปรดติดต่อเรา

โลหะผสมไททาเนียม รูปแบบทั่วไป: TI-6AL-4V, TI-5AL-2.5SN, TI-6AL-2SN-4ZR-6MO --------------------- พื้นที่แอพพลิเคชัน อวกาศ: ชิ้นส่วนเครื่องบิน ชีวการแพทย์: ตะปูสำหรับฟัน ตะปูกระดูก รถยนต์ระดับไฮเอนด์: ชิ้นส่วนรถแข่ง วิศวกรรมทางทะเล: ชิ้นส่วนเรือดำน้ำ อุปกรณ์ป้องกันการกัดกร่อน

| สแตนเลสอัลลอยด์สูง รูปแบบทั่วไป: 316L, 17-4PH, 2507 --------------------- พื้นที่แอพพลิเคชัน อุปกรณ์ทางการแพทย์: เครื่องมือผ่าตัด ตะปูสำหรับฟันและตะปูกระดูก เซมิคอนดักเตอร์: ชิ้นส่วนเซ็นเซอร์ รถยนต์: ตัวยึด เพลา

| เหล็กกล้าที่มีความแข็งแรงสูง รูปแบบทั่วไป: S355, AISI 4340, 42CRMO4, MARAGING 300 --------------------- พื้นที่แอพพลิเคชัน การบินและอวกาศ: ชิ้นส่วนโครงสร้าง, ตัวยึด ยานยนต์: ชิ้นส่วนที่มีความแข็งแรงสูง

|

Carbon fiber composite materials รูปแบบทั่วไป: T300, T700, T800, M55J --------------------- พื้นที่แอพพลิเคชัน อวกาศ: ลำตัวเครื่องบิน ปีกเครื่องบิน รถยนต์: ชิ้นส่วนสำหรับการแข่งขัน

| Aluminum alloy รูปแบบทั่วไป: 7075, 2024, 7050 --------------------- พื้นที่แอพพลิเคชัน อวกาศ: ชิ้นส่วนโครงสร้าง ยานยนต์: โครงตัวถัง ชิ้นส่วนน้ำหนักเบา อิเล็กทรอนิกส์: หม้อน้ำ ตัวเรือนโทรศัพท์มือถือ

| High-performance plastics รูปแบบทั่วไป: PEEK, PTFE, PEI, PPS --------------------- พื้นที่แอพพลิเคชัน ทางการแพทย์: อุปกรณ์ทางการแพทย์ อุปกรณ์ผ่าตัด เซมิคอนดักเตอร์: ชิ้นส่วนฉนวน

|

เวิร์คช็อป

ยินดีต้อนรับเข้าเยี่ยมชมโรงงานของเราได้ตลอดเวลา

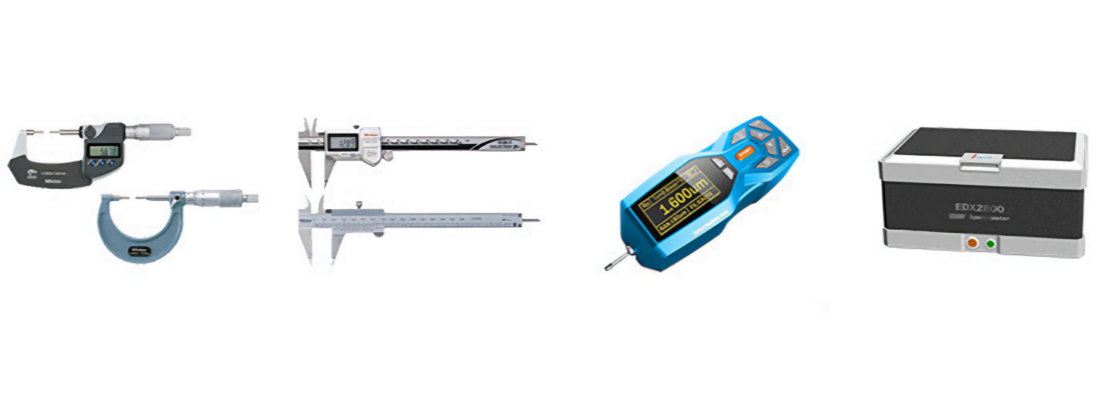

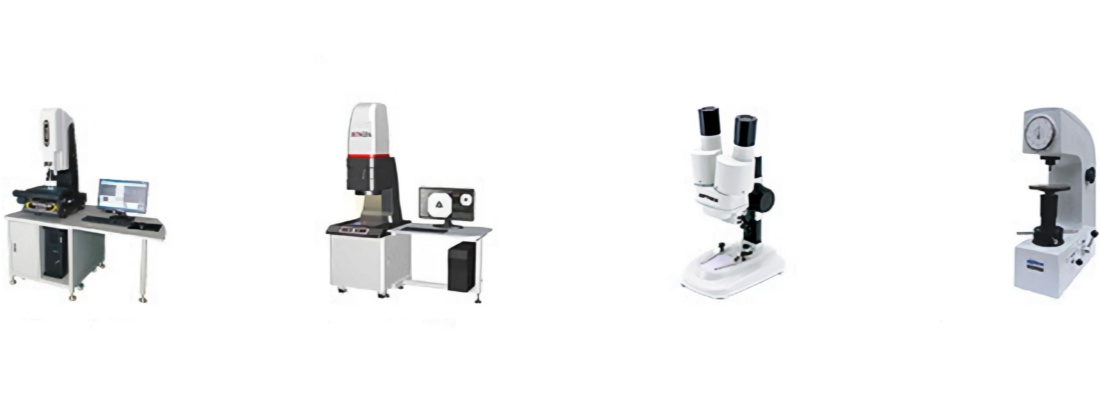

คุณสามารถมั่นใจได้ในคุณภาพของอุปกรณ์ทดสอบของเรา

ไมโครมิเตอร์ เวอร์เนียร์คาลิปเปอร์ เครื่องทดสอบความหยาบผิว เครื่องทดสอบสภาพแวดล้อม

อุปกรณ์ 2D เครื่องทดสอบแฟลช กล้องจุลทรรศน์ เครื่องทดสอบความแข็งร็อคเวลล์

พารามิเตอร์ผลิตภัณฑ์

ประเภทการกลึง | การเปลี่ยนแปลง | ความแม่นยำในการประมวลผล | งานตกแต่ง |

ประเภทการกลึง | เครื่องกลึงซีเอ็นซี | วัสดุแปรรูป | สแตนเลส、ทองเหลือง、อลูมิเนียมอัลลอยด์ |

เส้นผ่านศูนย์กลางสูงสุด | 200 (มม.) | ความยาวสูงสุด | 800 (มม.) |

ความอดทน | 0.01มม. | ความหยาบของพื้นผิว | Pa1.6 |

วงจรการพิสูจน์ | 1-3 วันทำการ | ระยะเวลาในการประมวลผล | 4-7 วันทำการ |

กำลังการผลิตคงเหลือต่อปี | 1,000,000 (รายการ) | ความสามารถในการประมวลผลสูงสุดต่อปี | 5,000,000 (รายการ) |

กระบวนการปรับแต่งที่ไม่เป็นมาตรฐาน

| 1. ติดต่อเราทางออนไลน์เพื่อสอบถามความต้องการของคุณ | 2. ส่งแบบร่างมาให้เราเพื่อสอบถามความต้องการปรับแต่ง | 3. ยืนยันกระบวนการและใบเสนอราคาเบื้องต้น | 4. เซ็นสัญญาและชำระเงินมัดจำ |

| 5. ทำตัวอย่างเพื่อการยืนยันของคุณ | 6. การผลิตจำนวนมากและการตรวจสอบคุณภาพ | 7. ยืนยันและชำระเงินส่วนที่เหลือ | 8.ส่งมอบให้กับลูกค้า |

การจัดการคุณภาพ ISO

1. ตรวจสอบวัสดุ

2. ตรวจสอบตัวอย่าง

3. การตรวจสอบของหัวหน้างาน

4. การทดสอบตัวเอง

5. จัดเตรียมการขนส่ง

6. บรรจุภัณฑ์หลายชั้น

7. การตรวจสอบการขนส่ง

8. การทดสอบ QA