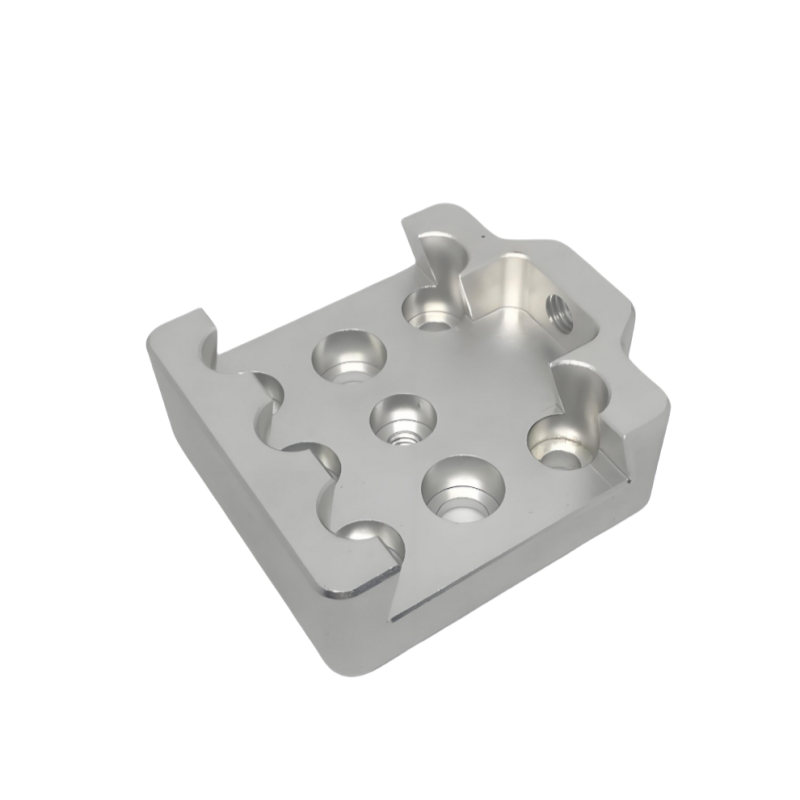

Product Description

We specialize in the production of various precision hardware parts, and have dozens of high-speed precision automatic lathes, CNC lathe screw machines and peripheral equipment. We specialize in processing various precision hardware parts and national standard and non-standard fasteners, and apply model aircraft and drone accessories, packaging machinery accessories, lighting hardware accessories, pneumatic accessories, testing equipment accessories molds, etc.

Application

CNC technology is the core support for oil equipment manufacturing. Its high precision, flexibility and automation characteristics directly improve the industry's safety, efficiency and cost control capabilities. With the iteration of technology, the oil industry will be further promoted to develop in the direction of intelligence and lightweight in the future.

CNC is used in the medical industry to manufacture orthopedic implants, dental instruments and surgical tools. Biocompatible materials such as titanium alloys are used to ensure the precise matching of implants and human tissues through high-precision processing, thereby improving the success rate of surgery and the patient's recovery effect.

CNC is used in the home appliance industry to process air-conditioning shells, refrigerator liner, small appliance precision molds, etc. It realizes complex curved surface modeling through high-speed milling of aluminum alloys/plastics, improves the accuracy of core components such as heat sinks and motor shafts, and ensures batch production consistency and product durability.

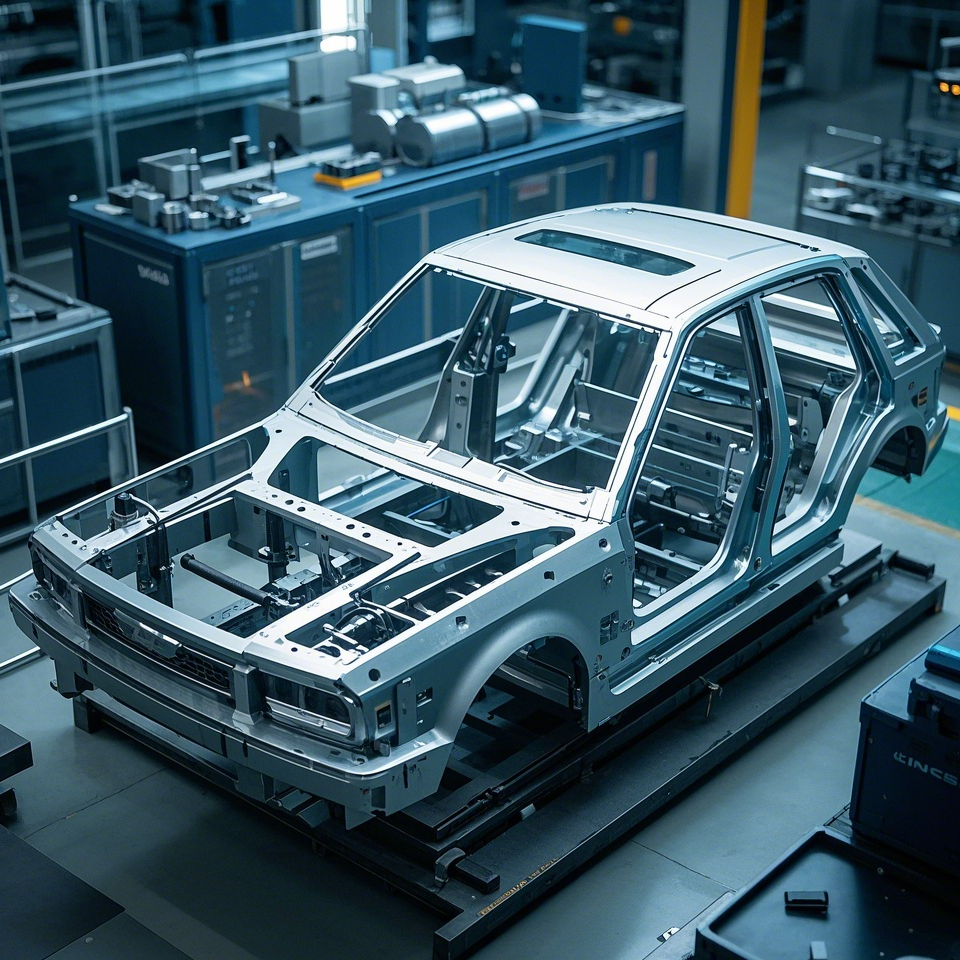

CNC is used in the automotive and shipbuilding industries to manufacture engine cylinders, gearbox gears, marine propellers and hull structural parts. High-strength alloys/composite materials are used for precision processing to achieve complex curved surfaces and high-precision tolerance control, improve power system efficiency and ship corrosion resistance, and meet the needs of large-scale production.

The application of CNC (computer numerical control) technology in the aerospace field has become the core force driving innovation in the aerospace manufacturing industry. Its high-precision, intelligent and diversified processing capabilities support the manufacturing of the entire industry chain from satellites to rockets.

Raw material

Stainless steel

High temperature alloy

Aluminum alloy

Magnesium alloy

Titanium alloy

Copper alloy

Product parameters

Main services | CNC processing, hardware processing, surface treatment, metal casting, mold processing |

Main industries | Metal shell processing, welding processing, CNC processing, stamping processing, laser processing, metal panel processing |

Processing accuracy | Fine grinding(Customized as needed) |

Maximum diameter | 0.1mm |

Tolerance | 0.1mm |

Maximum length | 10mm |

Surface roughness | 0.1 μm |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Production processes

The tool arrangement machine adopts an inclined bed structure, equipped with a multi-tool high-precision cutting system, suitable for metal/non-metallic materials, to achieve efficient and stable processing, and meet the needs of precision manufacturing.

The CNC machine adopts a high-precision CNC system, supports multi-axis linkage, and is equipped with a 24-tool automatic tool changer, suitable for metal/non-metallic materials, to achieve efficient and precise milling and drilling processing, and the positioning accuracy reaches ±0.005mm.

The tool arrangement machine adopts an inclined bed height and high rigidity structure, equipped with precision guide rails and multi-station cutting systems, supports composite processing such as turning and drilling, and is suitable for metal/non-metallic materials, to achieve efficient and stable production, and meet the needs of precision manufacturing.

The turning and milling compound machine tool integrates multiple processes such as turning, milling, and drilling, adopts an inclined bed height and high rigidity structure, supports multi-axis linkage and precision detection, and completes the efficient processing of complex parts in one clamping, with an accuracy of ±0.005mm, and is suitable for metal/non-metallic materials.

The turret CNC tailstock machine adopts a highly rigid structure with an inclined bed, equipped with a power turret and a hydraulic tailstock, supports multi-axis linkage and long-axis processing, has a positioning accuracy of ±0.003mm, is suitable for metal/non-metallic materials, and achieves efficient and precise production.

Quality Control Equipment

The roughness meter is the core equipment of industrial quality control. It uses contact stylus or non-contact optical technology to accurately quantify the surface micro-morphology. It uses high-precision sensors to capture peaks and valleys and is widely used in mechanical manufacturing, electronic components and aerospace.

The two-dimensional imager is a precision measuring device based on optical imaging and digital image processing technology. It is mainly composed of high-resolution CCD lens, continuous zoom objective lens, precision grating ruler and intelligent measurement software. It is widely used in electronic components, precision molds, PCB boards and other fields.

Two-dimensional plane measurement equipment (such as two-dimensional imagers) is based on optical imaging and digital image processing technology. It can non-contactly measure the plane size, contour and form and position tolerance of the workpiece to achieve sub-micron accuracy. It is widely used in precision machinery, electronic components and other fields.

The three-dimensional coordinate measuring machine is a high-precision three-dimensional detection equipment. It scans the workpiece in contact or non-contact through the X, Y, and Z three-axis linkage to obtain geometric dimensions, form and position tolerances and surface data. The equipment has the characteristics of fully automatic measurement, multi-sensor compatibility and strong environmental adaptability. It is widely used in the fields of automobiles, aerospace, molds, electronics, etc., significantly improving the quality control efficiency of the manufacturing process.

Additional processes

High-frequency vibration technology is used to quickly remove burrs and oxide layers on the workpiece surface to achieve mirror-level polishing effect. It is suitable for precision processing fields such as automotive parts, electronic components, and handicrafts. It is easy to operate, saves time and effort, and significantly improves product quality and production efficiency.

Using electrochemical principles, anodic dissolution can quickly remove burrs and scratches on the metal surface to achieve micron-level mirror polishing. It is widely used in high-end manufacturing fields such as aerospace and precision molds to improve workpiece precision and corrosion resistance.