Product Description

The company undertakes structural parts, machining, high-precision, high-difficulty, non-standard mechanical parts. It has high-speed four-axis and five-axis CNC computer gong processing center, CNC lathe, milling machine, grinder, drilling machine, polishing machine,testing equipment and other equipment. Faster and higher quality ensures the processing accuracy of mechanical parts.

Application

CNC machining parts are widely used in automobile manufacturing (engine cylinder, transmission gear), aerospace (turbine blades, frame structure), medical equipment (surgical instruments, implants), electronic communications (precision connectors, heat dissipation modules), mold manufacturing (injection molds, stamping molds), energy equipment (nuclear power components, wind turbine blades) and other fields. With high-precision and complex shape processing capabilities, it meets the precision manufacturing needs of various industries for metals and composite materials.

Raw material

Aluminum alloy

Copper alloy

Stainless steel

Titanium alloy

Magnesium alloy

High temperature alloy

Product parameters

Main services | CNC machining, hardware machining, surface treatment, metal casting, mold machining |

Minimum wall thickness that can be processed | 0.2mm |

Dimensional accuracy | ±0.01mm |

Maximum processing size | 1200mm |

Processable surface roughness | 0.8μm |

Surface treatment process | Oxidation/electroplating/laser carving/brushing/polishing, etc. |

Machining type | Robots, aerospace, automobiles |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

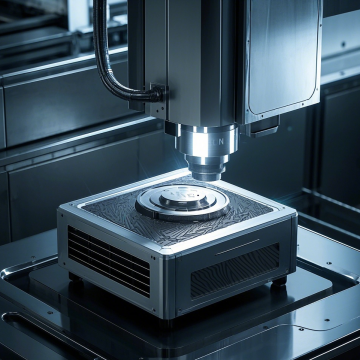

Production processes

24000 meters/min, 48m/min, 21T front, 24000 meters, ±0.005mm, ±0.005mm 3C will provide you with the latest technology and services.

The tool arrangement machine adopts a 30° inclined bed design with a positioning accuracy of ±0.005mm. It supports multi-material processing such as hard metal/plastic, and has a T-type tool arrangement for quick tool change.

Domestic CNC vertical processing machine, high-precision positioning ±0.003mm, supports multi-material processing such as hard metal/plastic, equipped with 24 disc tool magazines, automatic tool changing by robot, suitable for efficient production of complex parts such as automobiles and molds.

Turning and milling compound machine tools, integrated processing of the entire process, high-precision positioning of ±0.005mm, support for multi-axis linkage of hard metal/composite materials, equipped with a powered turret for automatic tool change, suitable for efficient production of complex precision parts in the automotive, aerospace and other fields.

The turret CNC tailstock machine has a 30° inclined bed structure with a hydraulic tailstock, and the servo turret supports 12-station automatic tool change. The positioning accuracy is ±0.003mm, which is suitable for efficient multi-process processing of complex parts such as automobiles and molds, and has high rigidity and multi-material adaptability.

Quality Control Equipment

The coordinate measuring machine is a high-precision three-dimensional inspection equipment that can achieve precise measurement of workpiece geometric dimensions, form and position tolerances, and surface data through multi-axis linkage. It can realize incoming material inspection, process optimization, and reverse engineering, significantly improving the quality control efficiency of the manufacturing process.

The industrial laser scanning probe is integrated with the CNC system to achieve efficient two-dimensional plane measurement. The equipment projects a laser beam onto the surface of the workpiece, uses the principle of triangulation to obtain dense point cloud data, and quickly generates a two-dimensional contour map.

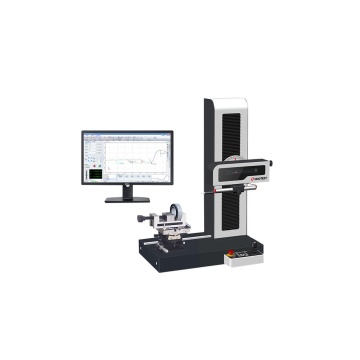

High-precision contact height gauges (such as the NS series) use sub-angstrom displacement sensors and single-arch gantry structures to non-contact scan nanometer to hundreds of micron step morphology, supporting roughness, waviness, and stress analysis. Its multi-area automatic measurement mode and 3D reconstruction function are suitable for precision device inspection such as semiconductor wafers and optical components.

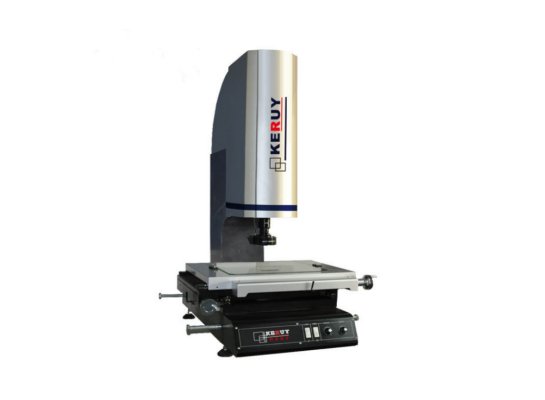

The two-dimensional imager has become a key inspection tool in the field of industrial manufacturing with its high precision and intelligent characteristics. The equipment adopts a granite base and precision guide rail design, combined with light source and coaxial light technology to optimize imaging quality. Its measurement range covers small to medium-sized workpieces, and can realize fully automatic measurement of basic elements such as points, lines, circles, arcs, etc., and supports offline programming and batch testing.

The two-dimensional imager has become a key inspection tool in the field of industrial manufacturing with its high precision and intelligent characteristics. The equipment adopts a granite base and precision guide rail design, combined with light source and coaxial light technology to optimize imaging quality. Its measurement range covers small to medium-sized workpieces, and can realize fully automatic measurement of basic elements such as points, lines, circles, arcs, etc., and supports offline programming and batch testing.

Surface Treatment

Anodizing uses an electrochemical process to generate an oxide film on the metal surface, which improves corrosion resistance and wear resistance, supports dyeing and insulation treatment, and is widely used in light metal precision parts such as aluminum and magnesium.

Laser marking uses a high-energy laser beam to etch permanent marks on the surface of materials, achieving high-precision, non-contact processing, supporting QR code/serial number traceability, and is suitable for complex scenarios with multiple materials such as metals and plastics.