Huraian Produk

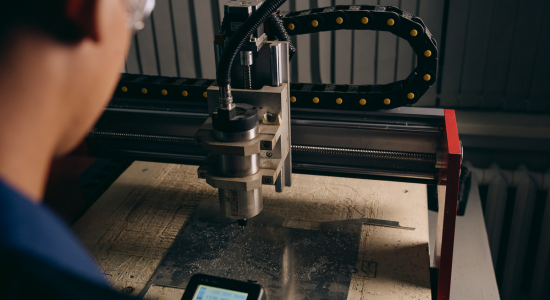

BasikalFix LogamTahan menawarkan pengapit keluli tahan karat dan aluminium mesin CNC yang tahan lama, direka untuk pemasangan yang tepat dan selamat dalam aksesori basikal, memastikan prestasi tahan lama dan integriti struktur. Dicipta untuk aplikasi tekanan tinggi dan keadaan tunggangan yang sukar, setiap bahagian memberikan ketahanan yang sangat baik terhadap haus, kakisan dan hentaman—sempurna untuk penunggang kasual dan penunggang basikal profesional yang mencari kualiti tanpa kompromi.

Parameter produk

Proses Suai

1. Siasatan

2. Rundingan

3. Tempoh Pembayaran

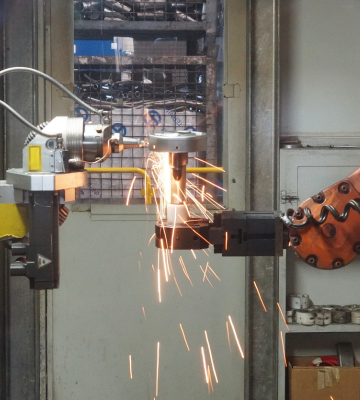

4. Pengeluaran Pemesinan

5. Sampel pemeriksaan

6. Pakej

7. Pengangkutan

8. Sokongan selepas jualan

Jenis Proses

Material

Aluminum

Brass

Stainless Steel

Plastics

Kawalan Kualiti

Kemampuan proses

Proses tambahan