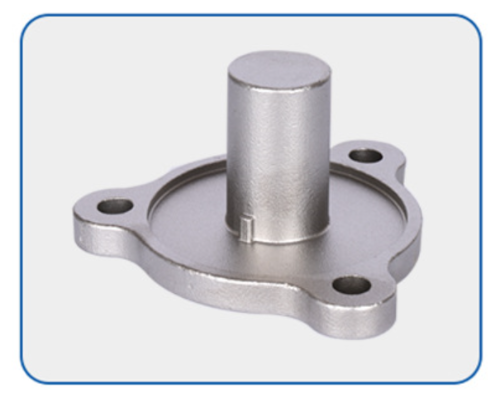

Product Description

Focus on non-standard castings processing according to drawings

Complete equipment, quality assurance, fast mixing, invoicing

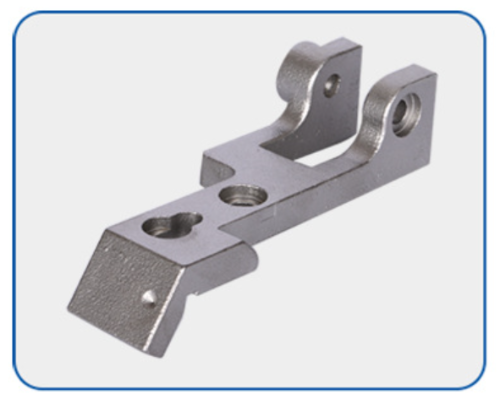

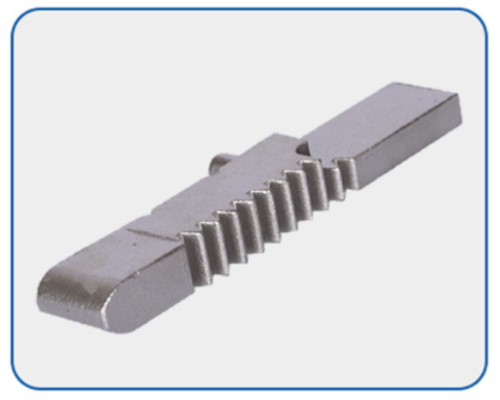

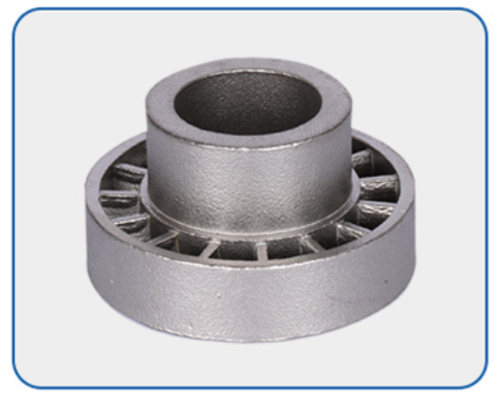

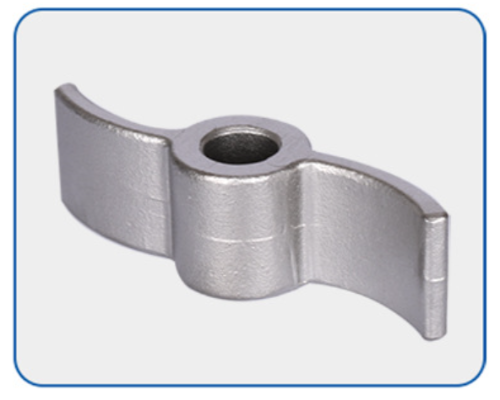

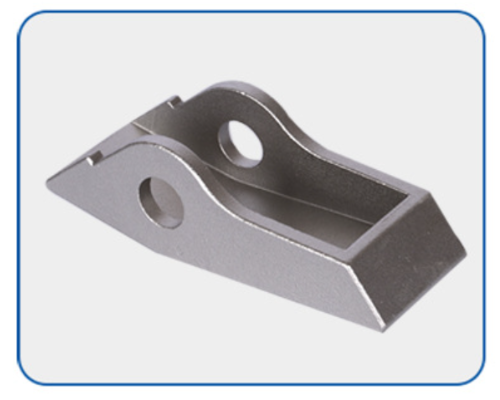

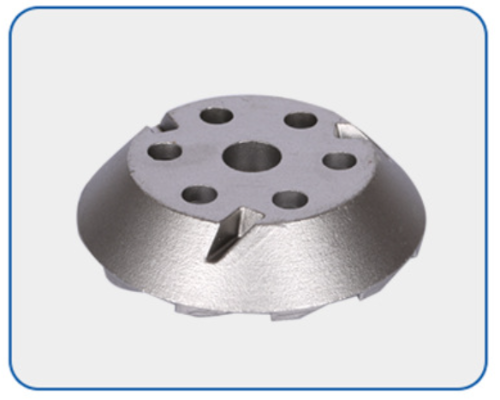

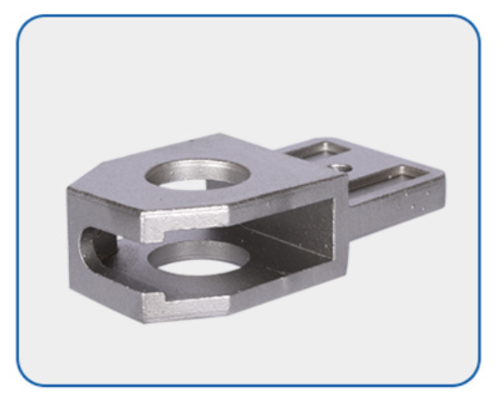

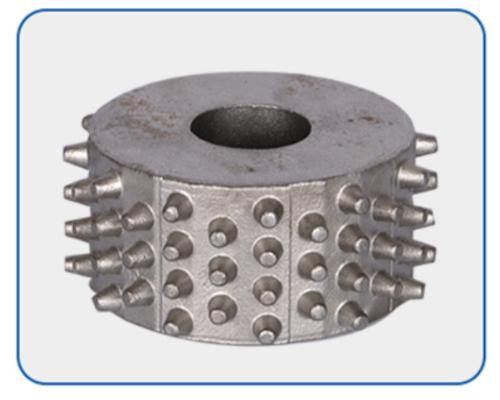

Product Display

Processing Product Case

Application

Aerospace

Automobile industry

Medical Devices

Agricultural machinery

Product parameters

Sand casting types | Silica Sol | Surface treatment process | Electrolysis, shot blasting, polishing, pickling |

Assembly service | Available | Processing materials | Stainless steel、Brass、Aluminum alloy |

Maximum diameter | 500 (mm) | Minimum length | 10 (mm) |

Tolerance | ±0.2mm | Surface roughness | 0.01 |

Sample production time | 4-7 workdays | Processing time | 8-15 workdays |

Annual remaining processing capacity | 1,000,000 (items) | Annual maximum processing capacity | 1,000,000 (items) |

Custom Process

1. Send drawings

2. Quotation

3. Sample confirm

4. Cooperation

Factory Display

Casting Process/ Factory Show

Foundry workshop

We have two casting production lines and can undertake large-volume production and processing.

Wax injection workshop

Silica sol wax injection workshop, with more than 10 equipment

Slurry dipping workshop

Large constant temperature slurry dipping workshop

Post-processing workshop

Casting surface post-treatment precision polishing

Why choose us?

1. With many years of experience in precision casting, we guarantee consistent quality and reliable service.

2. Our factory is equipped with advanced facilities and skilled technicians, ensuring every casting meets high industry standards.

3. Trusted by clients worldwide, we specialize in producing complex and high-precision metal parts.

4. From mold design to final inspection, we provide end-to-end manufacturing solutions.

5. We are committed to delivering precision, durability, and value in every product we manufacture.

6. Partner with us for stable quality, fast lead times, and responsive service.

7. Our expertise in investment casting allows us to serve various industries, including automotive, robotics, and aerospace.

8. Customer satisfaction is our top priority—your success is our success.