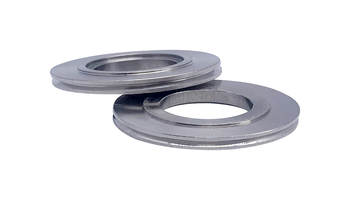

คำอธิบายผลิตภัณฑ์

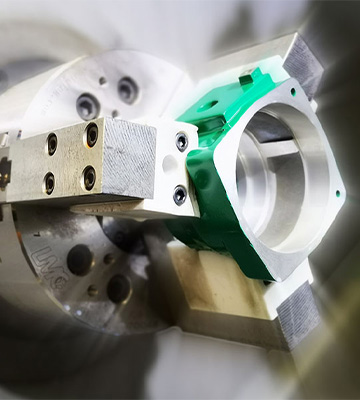

บริการเครื่องจักรกล CNC แบบ OEM ระดับพรีเมียม เพื่อความแม่นยำสูงและค่าความคลาดเคลื่อนที่ต่ำที่สุด

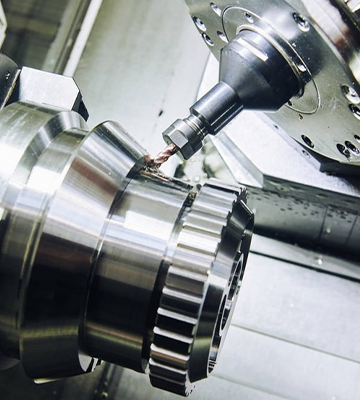

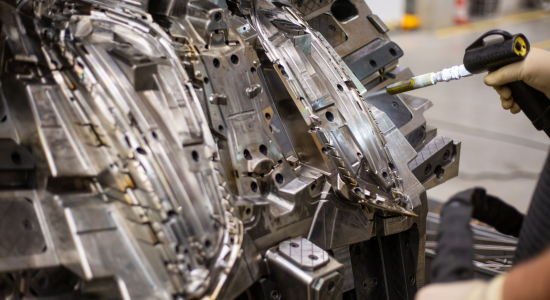

เรามีความเชี่ยวชาญในการผลิตชิ้นส่วนโลหะและพลาสติกแบบกำหนดเอง โดยใช้เครื่อง CNC แบบ 3 แกน, 4 แกน และ 5 แกน

เหมาะสำหรับอุตสาหกรรมการบินและอวกาศ, ยานยนต์, การแพทย์ และงานอุตสาหกรรมทั่วไป

ระยะเวลาการผลิตรวดเร็ว พร้อมกระบวนการที่ได้รับการรับรองมาตรฐาน ISO และตรวจสอบย้อนกลับวัสดุได้ 100%

รองรับตั้งแต่การสร้างต้นแบบ (Prototype) ไปจนถึงการผลิตในระดับอุตสาหกรรมขนาดใหญ่

เป็นพันธมิตรที่เชื่อถือได้สำหรับคุณภาพที่สม่ำเสมอและการจัดส่งตรงเวลา

พารามิเตอร์ผลิตภัณฑ์

| Brand Name | บริการเครื่องจักรกล CNC แบบ OEM สำหรับความแม่นยำสูง |

| Material Capabilities | รองรับวัสดุ: อะลูมิเนียม, ทองเหลือง, ทองแดงผสม, ทองแดง, สแตนเลส, โลหะผสม, โลหะแข็ง, โลหะมีค่า |

| Type | ประเภทงาน: คว้าน, เจาะ, แกะสลัก/กัดเคมี, เลเซอร์, กัด, งานเครื่องจักรอื่น ๆ, ตัวอย่างต้นแบบเร็ว, กลึง, ตัดด้วยลวด EDM |

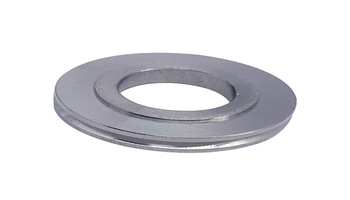

| Material | วัสดุ: ทองเหลือง / อะลูมิเนียม / สแตนเลส / พลาสติก / ทองแดง |

| Process | กระบวนการ: เจาะ / ดัด / กัด / กลึง / เลเซอร์ |

| Surface treatment | การเคลือบผิว: พ่นสี / เคลือบผง / ชุบ / ขัดเงา |

| Drawing Format | รูปแบบแบบ: 2D (PDF/CAD/DWG/DXF), 3D (IGES/STEP/VDA) |

| Tolerance | ค่าความคลาดเคลื่อน: 0.01 - ±0.005 มม |

| Service | บริการ: ผลิตตามแบบ OEM/ODM งาน CNC แบบกำหนดเอง |

กระบวนการที่กำหนดเอง

1. ส่งคำถาม

2. แบบแปลนหรือชิ้นตัวอย่าง

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. การผลิตจำนวนมาก

7. การทดสอบก่อนการบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

การกลึง

การเจาะ

บริการ CNC

วัสดุ

อลูมิเนียม

ทองเหลือง

ทองแดง

การควบคุมคุณภาพ

ใช้เครื่องมือตรวจสอบความแม่นยำสูง เช่น CMM, เวอร์เนียร์, ไมโครมิเตอร์ และอุปกรณ์วัดขั้นสูงอื่น ๆ

มีการตรวจสอบทั้งในกระบวนการผลิตและหลังการผลิตอย่างเข้มงวดในทุกขั้นตอน

เป็นไปตามมาตรฐาน ISO 9001 และมาตรฐานเฉพาะทางในแต่ละอุตสาหกรรม

มีบริการรายงานผลการตรวจสอบและใบรับรองวัสดุให้ตามคำขอ

มุ่งมั่นส่งมอบงานไร้ข้อผิดพลาด พร้อมพัฒนาและปรับปรุงคุณภาพอย่างต่อเนื่อง

ความสามารถในการประมวลผล

ขีดความสามารถในการผลิตที่ตอบโจทย์ชิ้นงานซับซ้อนและความแม่นยำระดับสูง

รองรับการกลึง CNC แบบ 3 แกน, 4 แกน และ 5 แกน สำหรับรูปทรงซับซ้อนและความละเอียดสูง

สามารถทำงานกับวัสดุต่าง ๆ เช่น อะลูมิเนียม, สแตนเลส, ไทเทเนียม, ทองเหลือง, พลาสติก และอื่น ๆ

ให้บริการกัด, กลึง, เจาะ, ต๊าปเกลียว, และการตกแต่งผิวขั้นสุดท้าย

รองรับค่าความคลาดเคลื่อนได้สูงสุดถึง ±0.005 มม. สำหรับชิ้นงานที่ต้องการความละเอียดระดับสูง

รองรับตั้งแต่การผลิตต้นแบบไปจนถึงการผลิตจำนวนมาก ด้วยปริมาณที่ยืดหยุ่น

เชื่อมต่อระบบ CAD/CAM อย่างมีประสิทธิภาพ เพื่อความรวดเร็วและแม่นยำในการผลิต