คำอธิบายผลิตภัณฑ์

บริการชุบเคลือบผิวโลหะ

SURFACE TREATMENT SERVICE

|

|

|

ชุบนิเกิ้ลแบบไม่ใช้ไฟฟ้า (EN/ELP/Ni-P) เป็นการชุบนิเกิ้ลที่เกิดจากปฏิกิริยาทางเคมี โดยไม่ใช้กระแสไฟฟ้า ในกระบวนการการจับตัวของโลหะที่ผิวหน้าวัตถุ เป็นโลหะผสมนิเกิ้ล-ฟอสฟอรัส ที่ผิวเคลือบมีความสม่ำเสมอเท่ากันทั้งชิ้นงาน | ชุบดีบุก (Sn) เป็นการชุบแบบใช้ไฟฟ้า การชุบดีบุกของเรามีการชุบ 2 แบบ คือ แบบเงา และแบบด้าน ซึ่งการชุบแต่ละแบบจะมีความแตกต่างกันที่เคมี และกระบวนการชุบ การชุบดีบุกเพื่องานด้านไฟฟ้า เช่น ตู้ไฟ สวิทซ์ไฟ ฯลฯ ช่วยป้องกันการกัดกร่อนของโลหะ และการนำไฟฟ้า | ชุบซิ้งค์ (Zn) เป็นการชุบโลหะด้วยไฟฟ้า การชุบซิ้งค์ส่วนใหญ่เป็นการชุบเพื่อความสวยงาม และป้องกันการเกิดสนิม การกัดกร่อนของชิ้นงาน ซึ่งของเราจะเป็นการชุบแบบ Zn ( Cr ³+ ) เป็นสูตร Alkaline โดยปราศจากไซยาไนด์ซึ่งเป็นมลพิษ |

|

|

|

ชุบนิเกิ้ลแบบใช้ไฟฟ้า (Ni) การชุบนิกเกิลด้วยไฟฟ้าเป็นกระบวนการชุบนิกเกิลบนชิ้นส่วนโลหะโดยใช้ตัวควบคุมกระแสไฟฟ้า | ชุบทอง (Au) การชุบทองเป็นทองคำชนิดแข็ง (Au 99.7%) มีคุณสมบัติการนำไฟฟ้าได้ดี บัดกรีได้ ทนต่อการกัดกร่อน ต้านทานการเกิดออกซิเดชัน | ชุบเงิน (Ag) การชุบเงินมีวัตถุประสงค์เพื่อป้องกันการกัดกร่อน และเพื่อความสวยงามของผิวโลหะ ซึ้งเงินมึคุณสมบัติเด่นคือ ไม่รวมกับออกซิเจน แต่ไวในการทำปฏิกิริยากับสารประกอบซัลไฟด์ และนำไฟฟ้าได้ดี มีทั้งแบบชุบเงินเงา และชุบเงินด้าน |

|

|

|

ชุบนิเกิ้ลดำ (BNi) เป็นการชุบโลหะแบบใช้ไฟฟ้า คุณสมบัตินิเกิ้ลดำ ป้องกันการเกิดสนิมที่ชิ้นงาน เพื่อความสวยงาม ใช้เพื่อไม่ให้เกิดการสะท้อนแสงของผิวชิ้นงาน | ชุบนิเกิ้ลโบรอน (Ni-B) ชุบนิเกิ้ลโบรอน ( Ni-B ) เป็นการชุบนิเกิ้ลที่เกิดปฏิกิริยาทางเคมี โดยไม่ได้ใช้กระแสไฟฟ้า ที่มีตัวเร่งปฏิกิริยาให้เกิดชั้นฟิล์มของโลหะ ผสมนิเกิ้ลโบรอนบนผิวชิ้นงานโลหะ | ชุบนิเกิ้ลเทปร่อน (Nickel/PTFE) การชุบนิเกิ้ลแบบไม่ใช้ไฟฟ้าแบบไม่ใช้ไฟฟ้าเป็นการชุบที่เติม PTFE เข้าไปในการชุบนิเกิ้ลที่มีความต้านทานการกัดกร่อนสูง การรวมอนุภาค PTFE บนพื้นผิวที่ชุบช่วยเพิ่มการหล่อลื่น |

|

|

|

ชุบทองแดง (Cu) การชุบทองแดงเป็นการชุบที่มีคุณภาพสูง เนื่องจากมีการนำไฟฟ้าที่ดีเยี่ยม และการชุบนั้นค่อนข้างจะสม่ำเสมอแม้ในรูปทรงที่ซับซ้อน | สังกะสีที่มีสีสัน ชั้นสังกะสีที่มีสีสันไม่เพียง แต่ให้การป้องกันสังกะสี แต่ยังแยกสื่อการกัดกร่อนผ่านชั้นฟิล์มสีเพิ่มความต้านทานการกัดกร่อน | การล้างด้วยกรด & การเคลือบผิว เป็นการล้างพื้นผิวด้วยกรด สำหรับกำจัดออกไซด์ออกจากโลหะและจะเป็นฟิล์มบาง ๆ บนพื้นผิวสแตนเลส |

วัสดุที่สามารถประมวลผลได้

ทองแดง,โลหะผสมสังกะสี, อลูมิเนียมและวัสดุฮาร์ดแวร์อื่น ๆ

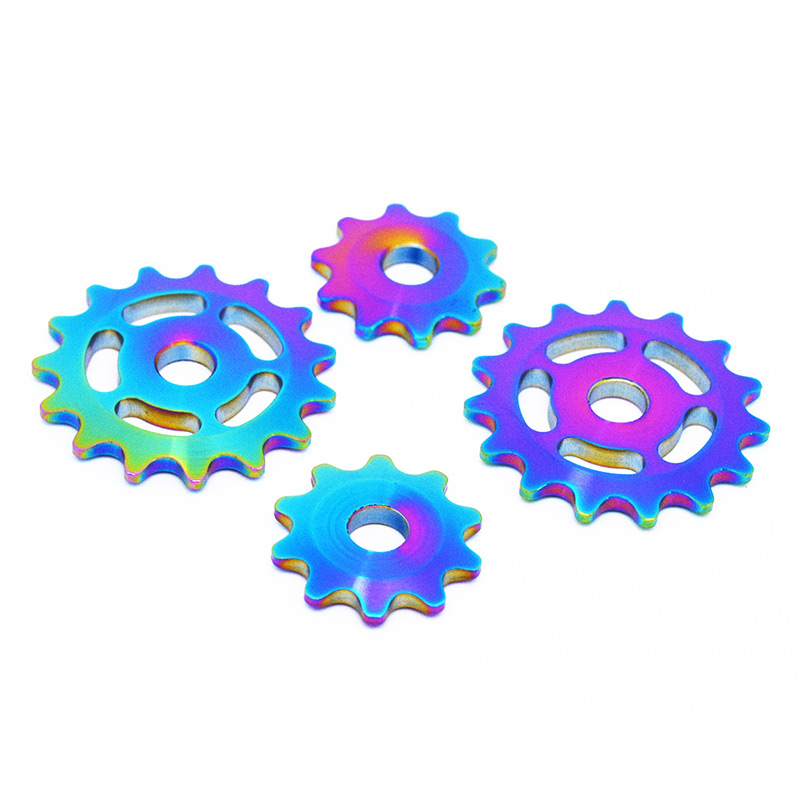

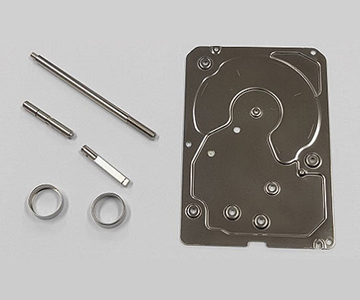

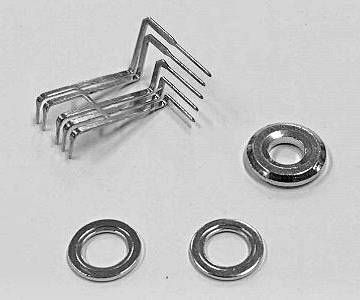

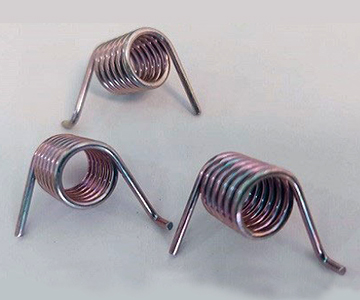

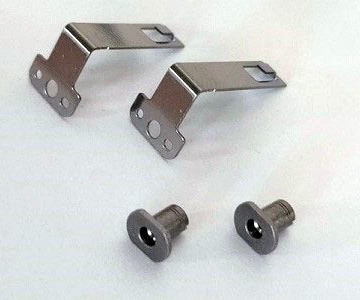

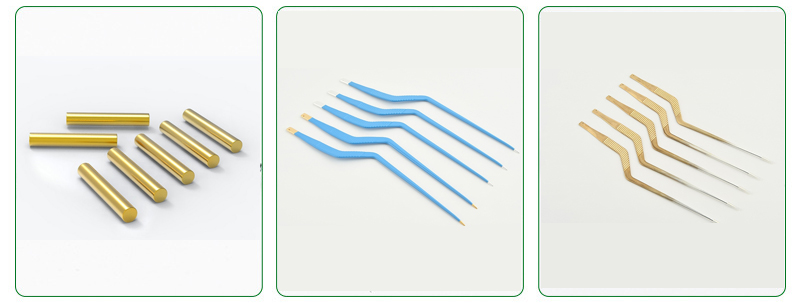

การแสดงสินค้า

Product Display

พารามิเตอร์ผลิตภัณฑ์

ขอบเขตธุรกิจของเรา

การรักษาพื้นผิว | บริการรักษาพื้นผิวครอบคลุมอโนไดซ์, ชุบ (ชุบสังกะสี, ชุบนิกเกิล, ชุบโครเมี่ยม ฯลฯ ), สเปรย์, passivation, การรักษาความร้อน, เคลือบ PVD ฯลฯ สามารถตอบสนองความต้องการของอุตสาหกรรมที่แตกต่างกัน |

อธิบายธุกิจ | การชุบและเคลือบผิวโลหะสำหรับชิ้นส่วนยานยนต์, ชิ้นส่วนHDD, ชิ้นส่วนอิเล็กทรอนิกส์, ชิ้นส่วนเครื่องไฟฟ้า, ชิ้นส่วนกล้องถ่ายรูป, ชิ้นส่วนอากาศยาน และชิ้นส่วนเครื่องมือแพทย์ (การชุบแบบใช้ไฟฟ้า, ไม่ใช้กระแสไฟฟ้า และทำความสะอาดชิ้นงานด้วยสารเคมี) |

ใบรับรอง | ISO 9001:2015, 14001:2015 |

กระบวนการที่กำหนดเอง

ความต้องการของลูกค้า

ปรับแต่งตามความต้องการ

ตัวอย่าง ส่งตัวอย่าง

ตัวอย่างยืนยัน

โลจิสติกส์แบบ door-to-door

การตรวจสอบการจัดส่งแบบเต็มรูปแบบ

การผลิตสินค้าขนาดใหญ่

ยืนยันการสั่งซื้อ

การควบคุมคุณภาพ

อุปกรณ์ควบคุมขั้นสูงเครื่องมือตรวจสอบและเทคโนโลยีกระบวนการชุบสามารถตอบสนองความต้องการด้านคุณภาพที่หลากหลายของลูกค้า

เครื่องมือวิเคราะห์

|

|

|

|

|

|

DIGITAL MICRO SCOPE VHX-7000 | X-RAY FLUORESCENCE FILM THICKNESS METER XRF-XDAL | ATOMIC ABSORPTION SPECTROPHOTOMETER AA-7000F | DIGITAL MICRO SCOPE VHX-6000 | FE-SEM-EDX JSM-IT300HR | SALT SPRAY TEST SALT-SPRAY |

ได้รับการรับรองมาตรฐานสากล ISO9001: 2015 (ระบบการจัดการคุณภาพ) และ ISO14001: 2015 (ระบบการจัดการสิ่งแวดล้อม) และเราจะปรับปรุงระบบการจัดการของเราอย่างต่อเนื่องโดยการประเมินและตรวจสอบอย่างสม่ำเสมอ