Product Description

Professional OEM CNC Machining Services – Non-Standard Precision Turning & Milling for Aluminum, Brass, and Automotive Components

We specialize in providing high-precision, non-standard CNC machining services tailored to complex requirements and tight tolerances. Our expertise includes both CNC turning and milling processes, allowing us to manufacture intricate aluminum, brass, stainless steel, and automotive parts with exceptional accuracy and repeatability. Whether it’s prototyping or low-to-medium volume production, we are fully equipped to handle custom geometries, non-standard dimensions, and special finishes.

Product details No fear of magnification

| Fine workmanship The whole is made of high-quality materials Not easy to wear and tear, long service life |

| Rigorous craftsmanship Use excellent inspection equipment Strict inspection of product dimensions Comply with product standards |

| Beautiful and practical Years of industry experience, fine workmanship Sturdy and durable, smooth and burr-free Long service life |

| Multiple specifications Various product specifications can be customized according to customer requirements |

Application Areas

Pump & Valve Industry |

Aerospace |

Navigation & shipping |

Building materials industry |

Medical industry |

Machinery industry |

Automotive industry |

Home appliance industry |

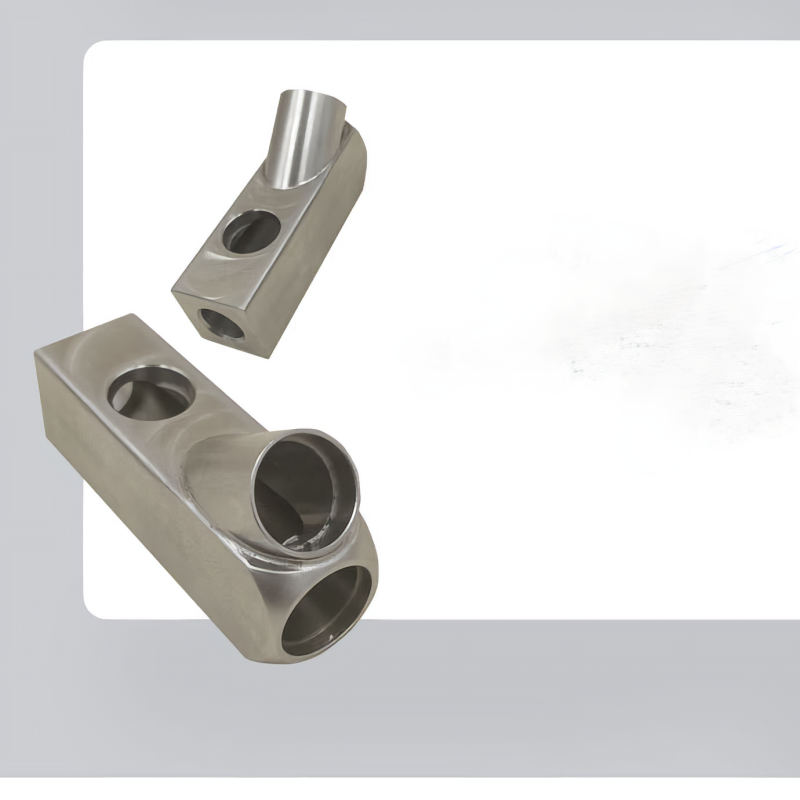

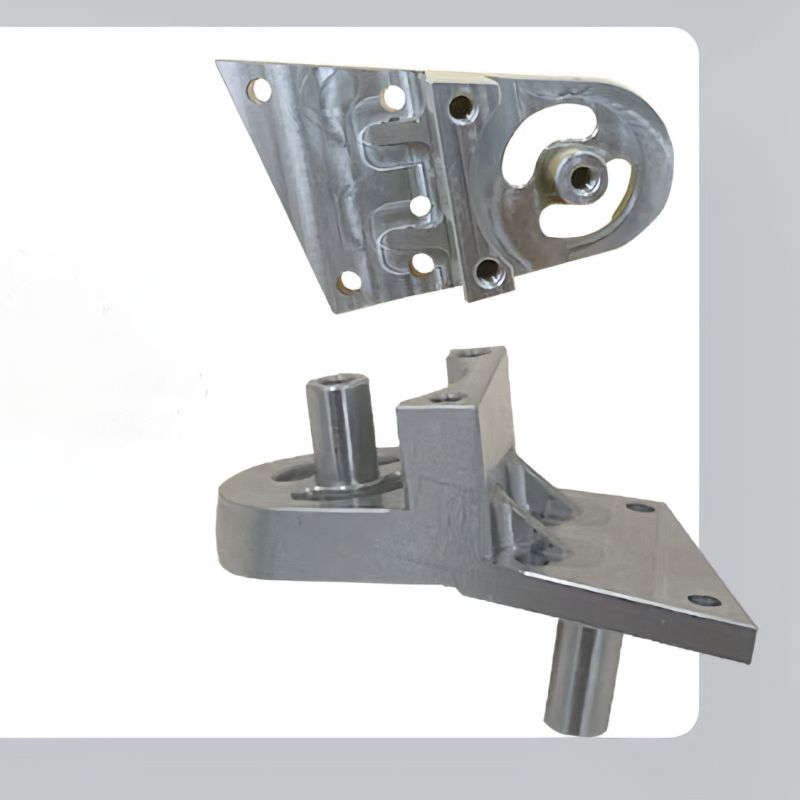

Product Display

CNC parts CNC turning parts Splice shafts-smooth shafts

Factory Advantages & Strengths

With over 10 years of experience in precision machining, our factory specializes in producing high-quality custom metal parts in both small and large batches. We are equipped with advanced machinery including 5-axis CNC machines and 3-coordinate measuring systems (CMM), allowing us to handle complex geometries and tight tolerances with confidence. Our commitment to fast, reliable quality inspection ensures that each product meets strict standards before delivery. Certified under the ISO 9001 Quality Management System (if applicable), we offer full-service support from initial design consultation to mass production—delivering dependable, turnkey manufacturing solutions tailored to your needs.

product images

Processing cases support customization

Strict testing, insisting on creating a platform with quality

Product parameters

Category | Customizable Details |

Material | Stainless Steel (e.g. 304, 316), Aluminum (e.g. 6061, 7075), Brass, Copper, Alloy Steel |

Machining Process | CNC Turning, CNC Milling, Drilling, Tapping, Grinding, Wire EDM |

Size Range | Customized per drawing (Max approx. 1000mm depending on equipment) |

Tolerance | Up to ±0.01–0.05 mm (depending on complexity) |

Surface Finish Options | Anodizing, Polishing, Sandblasting, Electroplating, Powder Coating |

Supported File Types | PDF, DWG, DXF, STEP, IGS, STL, etc. |

Minimum Order Quantity | 1 piece (varies with part complexity) |

Lead Time | 7–15 working days (based on quantity and complexity) |

Additional Services | Assembly, Special Packaging, Quality Reports (e.g., CMM, QC Inspection) |

Required Information from Customer Before Customization

Item | Description |

1. Machining Drawing | Technical drawing or 3D model in supported formats: STEP, IGS, STL, DWG, PDF, etc. |

2. Quantity Requirement | Specify the number of pieces required for production. |

3. Material & Tolerance | Specify the material (e.g. 304 SS, 6061 Aluminum) and dimensional tolerance. |

4. Surface Finish | Desired surface treatment: anodizing, polishing, powder coating, etc. |

5. Special Process Notes | Any special requirements such as thread types, hole dimensions, flatness, geometric tolerances, etc. |

Focus creates high quality Customer satisfaction is everything to us

Business scope

1. Material: Stainless steel, iron, copper, aluminum, titanium, alloy, plastic, and other engineering materials.

2. Processing Procedures: We offer one-stop non-standard precision machining services including CNC turning, CNC milling, drilling, tapping, knurling, flattening, grinding, and more.

3. Processing Equipment: Equipped with advanced CNC lathes, CNC machining centers, CNC turning and milling compound machines, automatic lathes, milling machines, drilling machines, grinders, etc.

4. Note: We specialize in the production of various standard and non-standard precision metal components, serving industries such as fishing hardware, electrical and electronic hardware, medical device components, instrumentation, automotive, aerospace, naval applications, and military manufacturing — with thousands of product types available for customer selection.

Purchase Notice

1、Our company specializes in non-standard customization, processing according to drawings and samples, no stock, please be advised!

2、The prices of all products in this store are not the actual prices of the products. Please consult the customer for quotation verification before placing an order. Orders placed without contact will be deemed invalid orders and will not be shipped. Please be aware of this and thank you for your cooperation.

3、If the customer does not respond to you in time, you can leave a message with your email and phone number and we will contact you later, or you can call us.

4、If it is not customized according to the customer's drawings, we will replace it for free and bear the domestic round-trip freight.

5、Quickly make samples in 3 days, and the minimum batch trial production can be 5 days, with fast delivery.

6、Customize strictly according to the dimensions on the drawings. If there are tolerance problems, we will replace it free of charge.

Cooperation Process

|

|

|

Contact customer service | Send drawings | Confirm drawings |

|

|

|

Shipping logistics | Customized production | Place order and pay |