Product Description

Aluminum

Material: 2024, 5052, 5083, 6061, 6061-T6, 6063, 6082, 7075, etc.

Tolerance: +/- 0.01~0.002mm

Key Features

Lightweight, corrosion-resistant

High thermal and electrical conductivity

Clean surface finish

Machining Notes

High spindle speeds and feed rates possible

Requires sharp tools for best finish

Chips easily, good for high-speed CNC milling

Applications: Aerospace parts, automotive components, electronics housings

Stainless Steel / Steel

Material: SUS303, SUS304, SS316, SS316L, 420, 430,17-4PH, 1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance: +/- 0.01~0.002mm

Key Features

Strong, corrosion- and heat-resistant

Durable and wear-resistant

Machining Notes

Requires lower speeds, high-quality carbide tooling

Generates more heat and tool wear

Coolant is essential to prevent work hardening

Applications: Medical devices, marine hardware, food processing equipment

Brass / Copper / Bronze

Material: HPb63, HPb62, HPb61, HPb59, H59, H62, H63, H65, H68, H70, H80, H90, C110, C120, C220, C260, C280, C360 etc.

Tolerance: +/- 0.01~0.002mm

Key Features

High electrical and thermal conductivity (especially copper)

Brass: Easy to machine, aesthetic appeal

Bronze: Strong, wear- and corrosion-resistant

Machining Notes

Brass: Minimal tool wear, great for precision parts

Copper: Requires sharp tools, generates burrs

Bronze: Good surface finish with proper tooling

Applications: Electrical connectors (copper) / Decorative fittings, valves (brass) / Bearings, bushings (bronze)

CNC Turning

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes

material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations

used.

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing

the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece

into a finished product.

CNC Drilling

CNC drilling is a machining process involving rotating cutting tools for producing round holes in a stationary workpiece. The

purposes of drilling are aesthetic ones or for further accommodating of screws and bolts.

Product Display

|

|

|

|

|

|

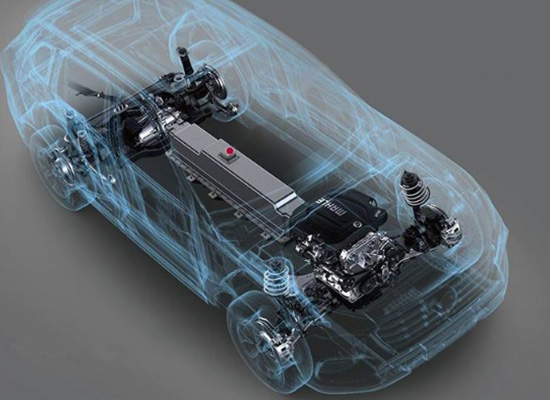

Application

Automotive Industry |

Electronics Industry |

Aerospace Industry |

Medical Devices |

Robotics & Automation |

Industrial Machinery |

Product parameters

Parameter | Specification | Parameter | Specification |

Material | Aluminum (6061, 7075, or per customer specification) | Application | Automotive, Aerospace, Electronics, Machinery, Medical Equipment |

Process | CNC Turning + CNC Milling | Drawing Format | PDF, DWG, DXF, STEP, IGS |

Tolerance | ±0.01 mm (custom tolerances available upon request) | Quality Control | 100% inspection; CMM, Calipers, Micrometers |

Surface Finish | Anodizing, Sandblasting, Polishing, or as required | Lead Time | 3–10 working days (depending on complexity and quantity) |

Size Range | Diameter: Ø1 mm – Ø300 mm; Length: up to 500 mm | Customization | Available (OEM/ODM supported) |

Thread Types | Metric, UNC, UNF, or custom | Packaging | Anti-rust bag + Bubble wrap + Carton or per customer requirement |

Custom Process

Contact

Negotiation

Mass Product

Transport

Quality Control

Incoming Material Inspection | Check Material Certification (e.g. 6061/7075 aluminum compliance) |

Visual inspection for surface defects, cracks, or deformation | |

Chemical and mechanical testing (if required) | |

In-Process Inspection | Dimensional checks using calipers, micrometers, gauges, and height meters |

First Article Inspection (FAI) for new production runs | |

Real-time process monitoring to detect tool wear or machine errors | |

Final Inspection | 100% dimensional inspection for critical parts |

Use of CMM (Coordinate Measuring Machine) for high-precision tolerance verification | |

Surface finish and thread quality checked according to customer specs | |

Hardness testing (if specified) | |

Documentation | Full Inspection Reports and Material Test Reports (MTRs) available upon request |

Certificates of Conformance (CoC) included with shipments | |

Traceable batch number system for all parts | |

Packaging Inspection | Ensure no damage, contamination, or oxidation before packing |

Cleanroom or anti-static packaging for sensitive parts (on request) |

Service

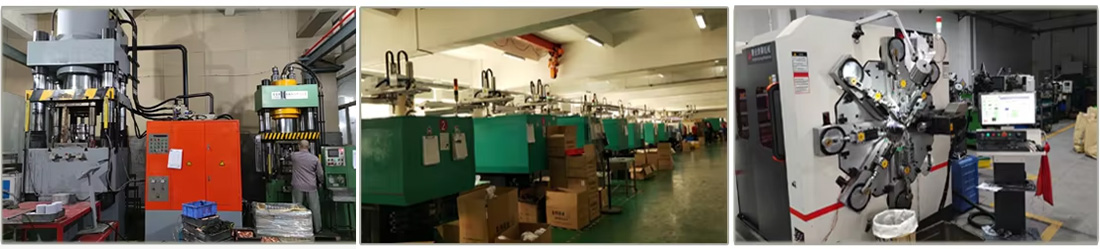

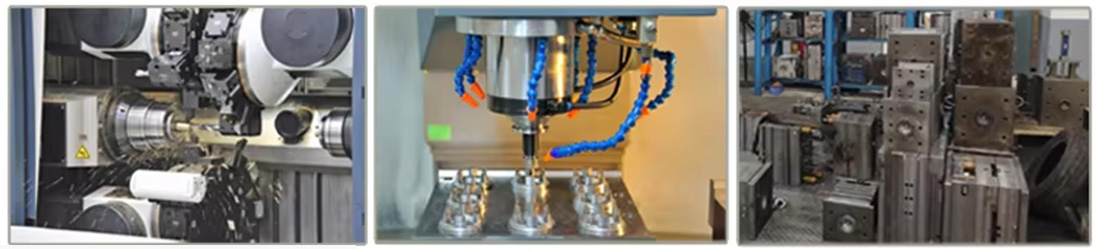

WORKSHOP FACILITY

Automatic Lathe CNC Machining Sheet Metal Stamping

Cold Extruding Plastic Injection Springs Machines

OUR SERVICE

CNC Turning CNC Milling Mold

Laser Cutting Stamping Cold Extruding

Spring Die Casting Plastic Injection

INSPECTON EQUITMENT

>Packing & Shipping

FAQ

Question | Answer |

What materials can you work with besides aluminum? | We primarily machine aluminum (6061, 7075, etc.), but we also handle stainless steel, brass, copper, titanium, and certain plastics like POM and PTFE. |

What is your typical lead time for production? | Lead times vary based on complexity and quantity. For standard parts, it’s usually 3–10 working days. Urgent orders can be expedited. |

Can you produce according to my drawings or samples? | Yes, we accept 2D/3D drawings in formats like STEP, IGES, DWG, or PDF. We can also reverse-engineer from physical samples. |

What surface finishes are available for aluminum parts? | We offer anodizing (clear, black, color), sandblasting, brushing, polishing, and powder coating, depending on your requirements. |

How do you ensure the quality of my parts? | We perform 100% inspection on critical dimensions using CMM, calipers, micrometers, and provide inspection reports and material certificates upon request. |