Product Description

Our Machining Aluminum Milling Parts Service provides high-precision CNC milling tailored to your exact specifications. We work with a wide range of aluminum materials, including 2024, 5052, 6061-T6, 6082, and 7075, ensuring the right material properties for your application. Using advanced CNC milling machines (3-axis, 4-axis, and 5-axis), we offer tight tolerances ranging from ±0.01 mm to ±0.002 mm, suitable for critical components in aerospace, automotive, electronics, medical devices, and industrial machinery.

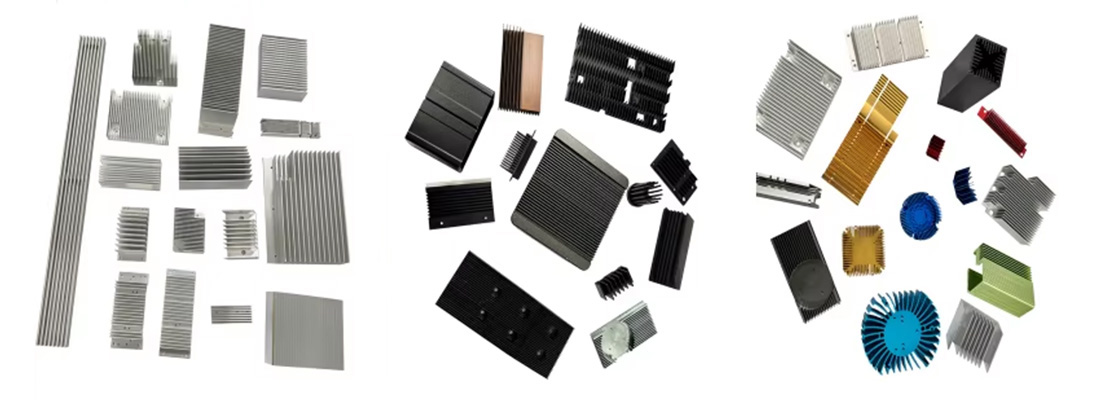

Surface finishes are fully customizable, including anodizing (color anodizing, black, or custom colors), sandblasting, polishing, powder coating, and more, to meet functional and aesthetic requirements. We accept 2D and 3D drawing formats such as PDF, STEP, IGS, DWG, and DXF. All parts undergo strict quality control using CMMs, calipers, micrometers, and thread gauges to ensure accuracy and consistency.

With flexible order quantities starting from just one piece, fast lead times of 3–10 working days, and full OEM/ODM support, we deliver both prototyping and mass production solutions. Each product is securely packaged using anti-corrosion materials and bubble wrap, with optional custom packaging available.

|

|

|

|

WHY CHOOSE US

Professional Team

| Expert Engineering Support

|

Economical Solutions

| High Quality

|

Feature

High Precision Machining | CNC (Computer Numerical Control) turning and milling machines provide exceptional accuracy—typically within ±0.01 mm or better. This ensures consistent part quality, tight tolerances, and perfect repeatability even for complex geometries. |

Multi-Axis Capability | CNC machines are often equipped with 3-axis, 4-axis, or 5-axis control, enabling the fabrication of intricate components from multiple angles in a single setup. This reduces the need for repositioning, improving both speed and dimensional accuracy. |

Versatile Material Compatibility | Supports a wide range of materials, including: |

Metals: Aluminum, steel, stainless steel, brass, copper, titanium | |

Plastics: ABS, POM, nylon, PTFE, PC | |

Composites and exotic alloys for aerospace or medical applications | |

Complex Geometries & Custom Shapes | CNC turning (for cylindrical parts) and milling (for flat and contoured surfaces) enable the creation of custom parts with internal bores, threaded features, undercuts, pockets, slots, and contours. |

Efficient Prototyping & Production | Ideal for both rapid prototyping and high-volume production runs. CNC machining allows for fast turnaround times without needing complex molds or dies. |

Automated & Repeatable Process | Programmed through CAD/CAM software, CNC machining ensures repeatability across thousands of parts, with minimal human error. |

Excellent Surface Finish | Offers high-quality surface finishes (Ra 0.8–1.6 µm typically), suitable for parts that require post-processing or tight cosmetic standards. |

Tolerance Control | CNC machining services can hold tight tolerances, depending on the application, as low as ±0.005 mm, meeting the requirements for aerospace, automotive, and precision medical parts. |

Cost-Efficient for Low to Medium Volumes | Compared to injection molding or die casting, CNC machining is more economical for small to medium batch sizes, especially when frequent design changes are involved. |

CAD/CAM Integration | Seamlessly integrates with 3D CAD models for direct-to-machine programming, improving efficiency and reducing errors during the transition from design to manufacturing. |

Product Display

CNC Machining

Heatsink

Metal Enclosure

Application

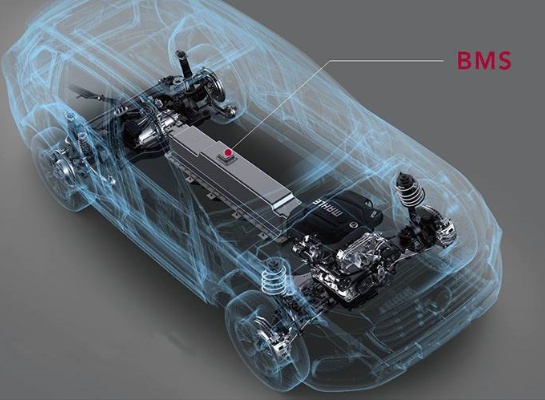

Automotive parts |

Aero dynamic parts |

Robotic parts |

Electric parts |

Medical parts |

Industry parts |

Product parameters

Parameter | Specification | Parameter | Specification |

Material | Aluminum (6061, 7075, or per customer specification) | Application | Automotive, Aerospace, Electronics, Machinery, Medical Equipment |

Process | CNC Turning + CNC Milling | Drawing Format | PDF, DWG, DXF, STEP, IGS |

Tolerance | ±0.01 mm (custom tolerances available upon request) | Quality Control | 100% inspection; CMM, Calipers, Micrometers |

Surface Finish | Anodizing, Sandblasting, Polishing, or as required | Lead Time | 3–10 working days (depending on complexity and quantity) |

Size Range | Diameter: Ø1 mm – Ø300 mm; Length: up to 500 mm | Customization | Available (OEM/ODM supported) |

Thread Types | Metric, UNC, UNF, or custom | Packaging | Anti-rust bag + Bubble wrap + Carton or per customer requirement |

Custom Process

CONTACT

NEGOTIATION

MASS PRODUCTION

LOGISTICS

Quality Control

QC Stage | Inspection Activities | Tools/Equipment Used | Purpose |

Incoming Material Check | - Verify material grade (e.g. 6061, 7075) | Material certificates, visual inspection | Ensure correct material and surface condition |

- Check for surface defects, oxidation, or damage | |||

In-Process Inspection | - Check dimensions during milling | Calipers, micrometers, gauges | Prevent errors during production |

- Monitor for tool wear or deviation | |||

First Article Inspection (FAI | - Full check on first part of each batch | CMM, height gauge, digital calipers | Approve setup before mass production |

- Confirm all dimensions match drawing | |||

Final Inspection | - 100% check on critical dimensions | CMM, thread gauge, micrometers, hardness tester | Verify part accuracy and meet customer requirements |

- Thread & surface finish inspection | |||

- Optional hardness test | |||

Documentation & Traceability | - Generate Inspection Report & Material Test Report | QC report forms, MTRs, CoC | Support traceability and documentation |

- Assign traceable lot numbers | |||

Packaging Check | - Ensure clean, undamaged parts | Visual inspection, cleanroom packaging (optional) | Protect parts during shipment |

- Anti-corrosion packing for sensitive parts |

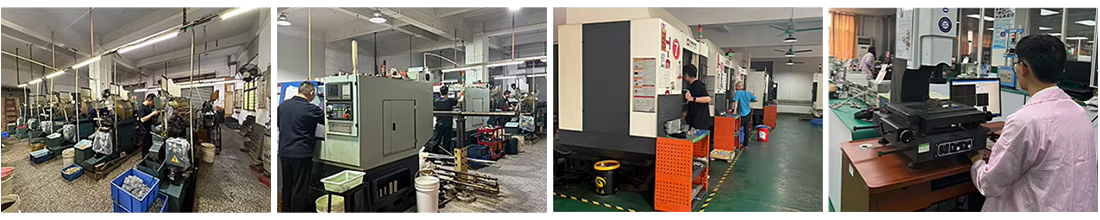

Production Workshop

1、LATHE CENTER 2、CNC TURNING CENTER 3、CNC MILLING CENTER 4、TESTING CENTER

FAQ

Q1.How long can I get the quotation?

A1: We are trying to quote within 24 hours, however it depends on drawing quantity and product complicated or not. If urgent, freely ask us to quote in priority.

Q2.How fast can I get samples?

A2: If the metal sample can be made without tooling, 3-7days. Otherwise, 7-15days.

Q3.Can I start trial order with small quantity before series production?

A3: Absolutely.

Q4.What’s the payment terms for mass production?

A4: 30% deposit, balance before shipping.

Q5.Is it possible to know my products producing status without a visit?

A5: Yes, we can email you with pictures or video frequently.

Q6.Can you keep my design safe? A6: Of course, non-disclosure agreement is available.