Product Description

Our CNC Metal Machining Service delivers high-precision, custom-machined metal parts tailored to your exact specifications. Using state-of-the-art Computer Numerical Control (CNC) technology, we work with a wide range of metals—including aluminum, stainless steel, brass, copper, titanium, and more—to produce components that meet the highest standards of accuracy and durability.

Functional Features

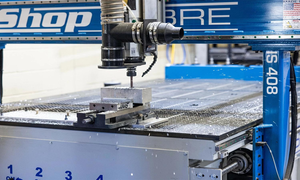

CNC Turning

| CNC Milling

|

Drilling

| Punching

|

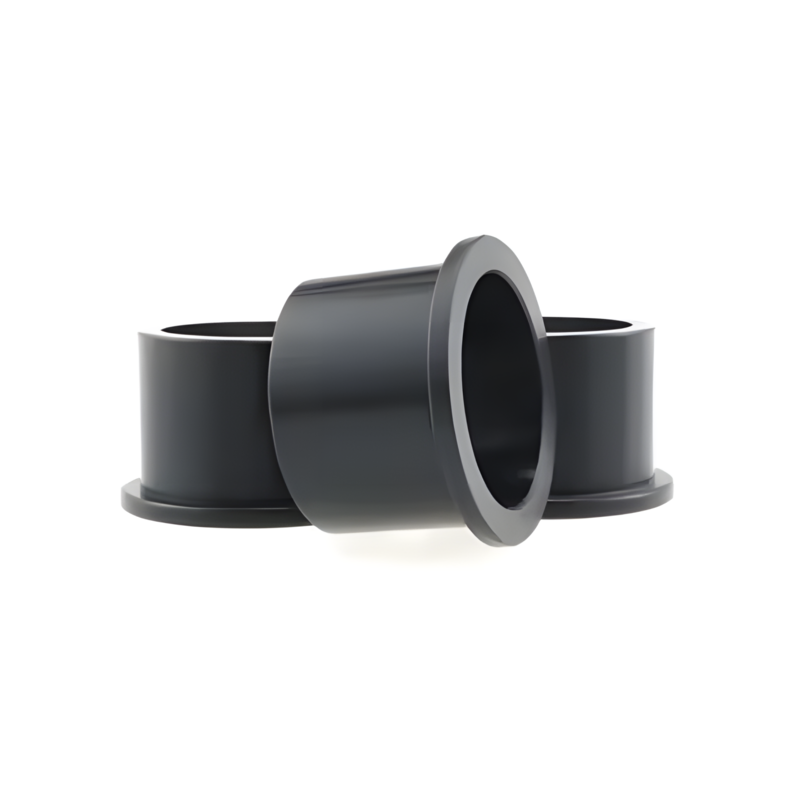

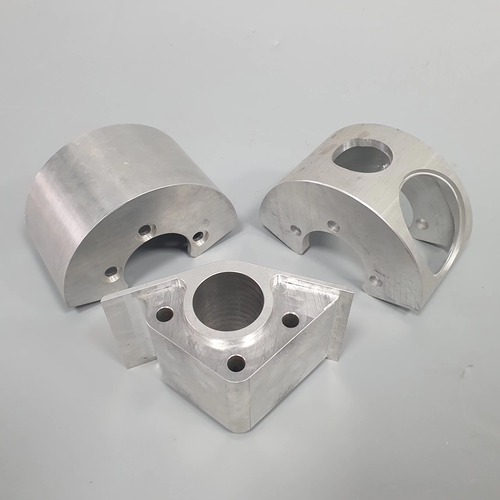

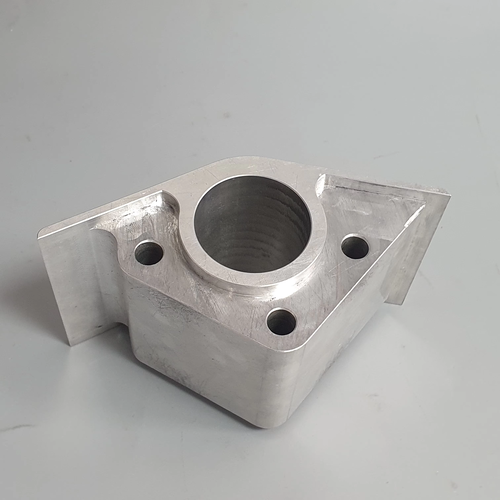

Product Display

Application

Our CNC Metal Machining Service provides high-precision custom parts manufactured from a wide range of metals. With cutting-edge 3-, 4-, and 5-axis CNC equipment, we offer unmatched accuracy, repeatability, and finish for demanding industries. Whether you need prototypes, low-volume production, or large-scale manufacturing, we ensure consistent quality and fast lead times.

| Feature | Specification |

| Supported Metals | Aluminum, Stainless Steel, Brass, Copper, Titanium, Steel Alloys |

| Machining Processes | Milling, Turning, Drilling, Boring, Tapping, Threading |

| Tolerance Range | ±0.005 mm (Standard), tighter upon request |

| Supported File Formats | DWG, DXF,STEP, IGES, STL |

| Minimum Order Quantity (MOQ) | No minimum for prototypes; scalable for high-volume |

| Surface Finishes | Anodizing, Powder Coating, Electroplating, Brushing, Polishing, Bead Blasting |

| Quality Control | In-process inspection, Final QC, CMM inspection, Material certification |

Industry Applications

|

|

|

|

|

| Aerospace & Defense | Automotive & Motorsport | Industrial Equipment & Automation | Medical & Dental | Electronics & Consumer Products |

Product parameters

| Parameter | Specification | Parameter | Specification |

| Material Options | Aluminum (6061, 7075, etc.), Stainless Steel (304, 316), Brass, Copper, Plastics | Thread Types | Metric, UNC, UNF, BSPT, or custom thread specifications |

| Machining Process | CNC Turning, CNC Milling, Drilling, Tapping, Threading, Boring, Surface Finishing | Inspection Methods | CMM, Calipers, Micrometers, Thread Gauges, Visual Inspection |

| Axis Configuration | 3-axis, 4-axis, 5-axis CNC Machines | Quality Control | 100% dimensional inspection with full traceability and reporting |

| Tolerance | ±0.01 mm standard, up to ±0.002 mm on request | Order Volume | From single prototype to high-volume mass production |

| Size Capacity | Up to Ø300 mm in diameter; Max length: 500 mm (customizable by part type) | Lead Time | 3–10 working days depending on complexity and quantity |

| Surface Finishes | Anodizing, Sandblasting, Polishing, Powder Coating, Electroplating, Brushing | Customization | OEM & ODM services available |

| Drawing Format | DWG, DXF,STEP, IGES, STL | Packaging | Anti-rust film + Bubble wrap + Protective carton or as per customer request |

Inspection equipment

Micrometer caliper |

Micrometer |

Digital height gauge |

Micrometer |

Three-coordinate measuring instrument |

Roughness meter |

Hardness tester |

Handheld spectrometer |

Custom Process

CONTACT

NEGOTIATION

MASS PRODUCTION

TRANSPORT

Quality Control

At our facility, Quality Control (QC) is an integral part of every stage of the CNC machining process to ensure that each product meets your exact specifications and industry standards. We adhere to strict inspection protocols and use advanced equipment to guarantee precision, consistency, and reliability.

Incoming Material Inspection

|

In-Process Inspection

|

First Article Inspection (FAI)

|

Final Inspection

|

Documentation & Traceability

|

Packaging Inspection

|

Service

From drawing analysis, process optimization to product delivery, we offer a one-stop solution. With strict quality control, fast delivery times and customized services, we help our customers enhance their product competitiveness. We are your reliable partner for precision manufacturing!

FAQ

1.How can I get CNC parts sample?

We also provide free samples in special conditions.

2.How about the lead time?

It depends on quantity, generally 7-20 days after order confirmation.

3.Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

4.I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

5.Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.