Product Description

Our CNC Machining Service for Shrapnel Cosmic offers high-precision milling and turning using computer-controlled machinery. It is ideal for producing complex parts with micron-level accuracy, supporting both prototyping and high-volume production.

Machine Types: CNC Milling, CNC Turning, Multi-axis machining (3, 4, and 5-axis)

Supported Materials: Aluminum, Stainless Steel, Titanium, Engineering Plastics, Copper, Specialty Alloys

Tolerances: ±0.005 mm or as specified

Production Capability: From prototyping to large-scale manufacturing

Processing features

High Precision: All components are machined with the utmost accuracy based on CAD/CAM designs

Design Flexibility: Supports production of intricate geometries and hard-to-reach features

Smooth Surface Finishes: Finishing and polishing services available to meet industrial standards

Reduced Lead Time: CNC processes ensure faster production with consistent precision

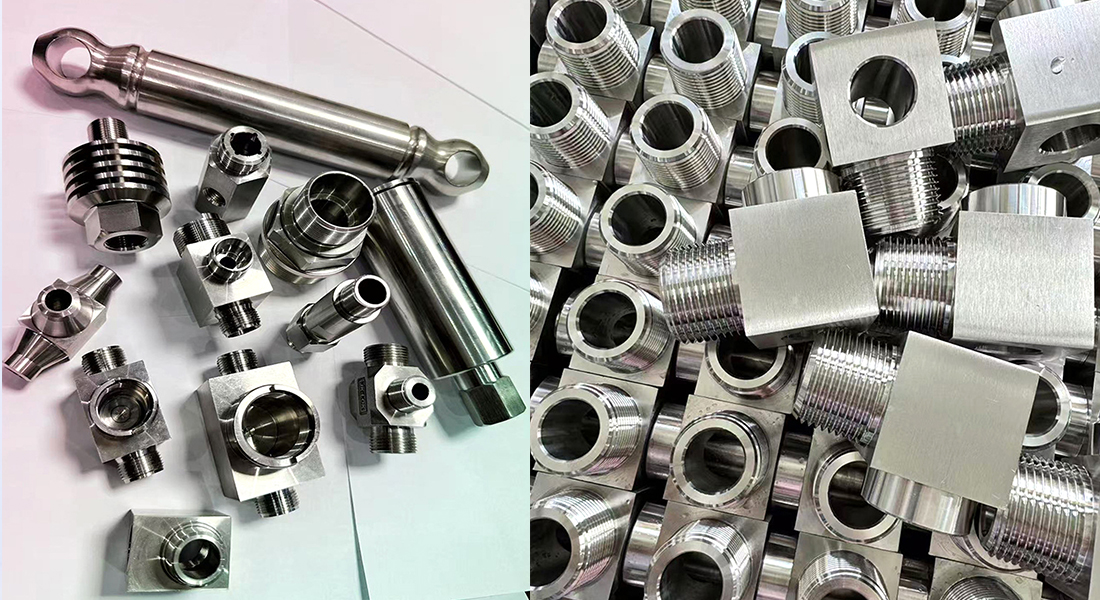

Product Display

Application

| Aerospace | Turbine blades, engine casings, landing gear parts | High precision, lightweight, heat resistance |

| Aerospace | Engine blocks, gear components, brake system parts | Durability, tolerance control, mass production capability |

| Medical | Surgical tools, bone implants, dental prosthetic | Biocompatibility, micro-machining, surface finish |

| Electronics | Heat sinks, device enclosures, connectors | Fine detail, thermal control, small form factor |

| Industrial Machinery | Shafts, gears, housings, custom fasteners | Strength, custom design, wear resistance |

| Defense/Military | Weapon components, drone frames, armored fittings | Strength, reliability, classified standard |

| Oil & Gas | Valve bodies, drill heads, pipeline connectors | Corrosion resistance, pressure tolerance |

| Robotics | Joints, brackets, end effectors | Precision, strength-to-weight ratio |

| Consumer Products | Watch cases, eyewear frames, custom housings | Aesthetic finish, compact design |

| Prototyping | Concept models, test parts, rapid iteration components | Speed, flexibility, design accuracy |

Product application

Mainly used in aerospace/semiconductor manufacturing/medical devices and bioengineering/precision instrument and equipment/industrial automation and robotics/mechanical industries, etc.

Aerospace Semiconductor Medical devices Mold industry

manufacturing

Product parameters

| Material | Aluminum, Stainless Steel, Brass, Titanium, Plastics |

| Processing Type | Turning, Milling, Drilling, Grinding, Threading |

| Tolerance | ±0.01 mm (or customized based on client requirements) |

| Surface Finish | Anodizing, Polishing, Sandblasting, Powder Coating, Electroplating |

| Size Range | Diameter: 1–300 mm, Length: up to 1000 mm (depending on machine capability) |

| Drawing Format | PDF, STEP, IGES, DWG, DXF |

| MOQ (Minimum Order Qty) | 1 piece (for samples) or based on project requirements |

| Lead Time | 3–15 days (depending on quantity and part complexity) |

| Inspection | CMM, Caliper, Gauge, Surface Roughness Tester |

| Application Industry | Automotive, Medical, Electronics, Aerospace, Machinery |

Custom Process

CONTACT

DRAWING

MASS PRODUCTION

TRANSPORT

Quality Control

| Dimensional Check | Use of Calipers, Micrometers, and CMM to ensure precise dimensions. |

| Visual Inspection | Check for surface defects, burrs, scratches, and finish quality. |

| Surface Roughness Measurement | Measured with a roughness tester according to required Ra values. |

| Thread Inspection | Use of thread gauges to verify internal and external threads. |

| Hardness Testing | Optional test for critical parts using Rockwell or Vickers methods. |

| Material Certification | Provide raw material certificates upon request. |

| Final Quality Review | 100% inspection for high-precision or critical parts before delivery. |

Factory shooting footage

Quality Assurance

| Certified Material Sourcing | All raw materials are sourced from verified suppliers with traceable certifications. |

| Process Standardization | All machining processes follow ISO or customer-defined procedures to ensure consistency. |

| Operator Training | Machine operators are trained and certified to handle complex CNC operations with precision. |

| Preventive Maintenance | Machines are regularly maintained to avoid breakdowns and ensure optimal machining accuracy. |

| Documentation and Traceability | Full documentation for each production batch including inspection reports, material certificates, and process records. |

| Continuous Improvement | Regular quality reviews and customer feedback are used to improve processes and product performance. |

| Compliance with International Standards | Adherence to ISO 9001, ISO 13485 (for medical), or other relevant industry standards. |

FAQ

Q: What materials can you machine?

A: We work with metals such as aluminum, stainless steel, brass, titanium, and plastics like POM, ABS, and nylon.

Q: What is your typical lead time?

A: Lead time varies by complexity and quantity, but typically ranges from 3 to 15 working days.

Q: What file formats do you accept for CNC machining?

A: We accept STEP, IGES, DWG, DXF, and PDF formats.

Q: Do you provide prototype and small batch machining?

A: Yes, we support prototypes, small-batch production, and high-volume orders.

Q: What is your tolerance capability?

A: Our general tolerance is ±0.01 mm, and tighter tolerances are available upon request.

Q: Can you provide surface treatments?

A: Yes, we offer anodizing, powder coating, polishing, plating, and more.

Q: Do you offer quality reports or certifications?

A: Yes, we can provide inspection reports, material certificates, and RoHS compliance upon request.