Product Description

Our Surface Spray Treatment service provides advanced protective and decorative coatings for metal components across a wide range of industries, including aerospace, automotive, electronics, and industrial equipment. This process involves the application of high-performance coating materials such as epoxy, polyurethane, fluoropolymers, and powder coatings, designed to enhance corrosion resistance, wear durability, UV protection, and aesthetic appeal.

Functional Features

| Material Compatibility | Suitable for aluminum, magnesium, titanium, zinc alloys, and other metal substrates |

| Customizable Finishes | Matte, satin, glossy, or textured finishes in a variety of standard or custom-matched colors |

| Precision Application | Coatings applied in controlled environments using industry-standard spray equipment and techniques |

| Durability | Excellent resistance to abrasion, chemicals, salt spray (ASTM B117), and temperatures up to 200°C |

| Environmentally Compliant | RoHS and REACH-compliant coatings, with low-VOC options available |

Why Choose Us

1. Expert Surface Coating Specialists

With years of experience in industrial coating, our team understands the chemistry, techniques, and standards required to deliver consistent, high-performance spray finishes for even the most demanding applications.

2. Strict Quality Control

Every project follows a detailed QC process, including real-time process monitoring, coating thickness validation, adhesion testing (ASTM D3359), and salt spray resistance (ASTM B117), ensuring durability and reliability.

3. Customization & Flexibility

From color matching (Pantone), gloss level, and surface texture to performance coatings tailored to chemical, UV, or thermal resistance—we provide custom solutions to match your exact design and performance needs.

4. Compliance & Sustainability

We offer RoHS- and REACH-compliant coatings, including low-VOC options, supporting your environmental goals and product compliance requirements.

5. Fast Turnaround & Full Traceability

With efficient processing, cleanroom application environments, and ISO 9001:2015-certified workflows, we deliver high-quality results with complete batch traceability—on time, every time.

Application

Protective coatings for machined parts, castings, and fabricated assemblies

Decorative finishes for consumer electronics, architectural hardware, and automotive trim

Functional coatings for non-stick, insulative, or anti-corrosive performance

Quality Assurance

Every part undergoes rigorous quality checks including:

Adhesion testing |

Coating thickness measurement |

Visual and gloss level inspections |

Salt spray testing for selected samples |

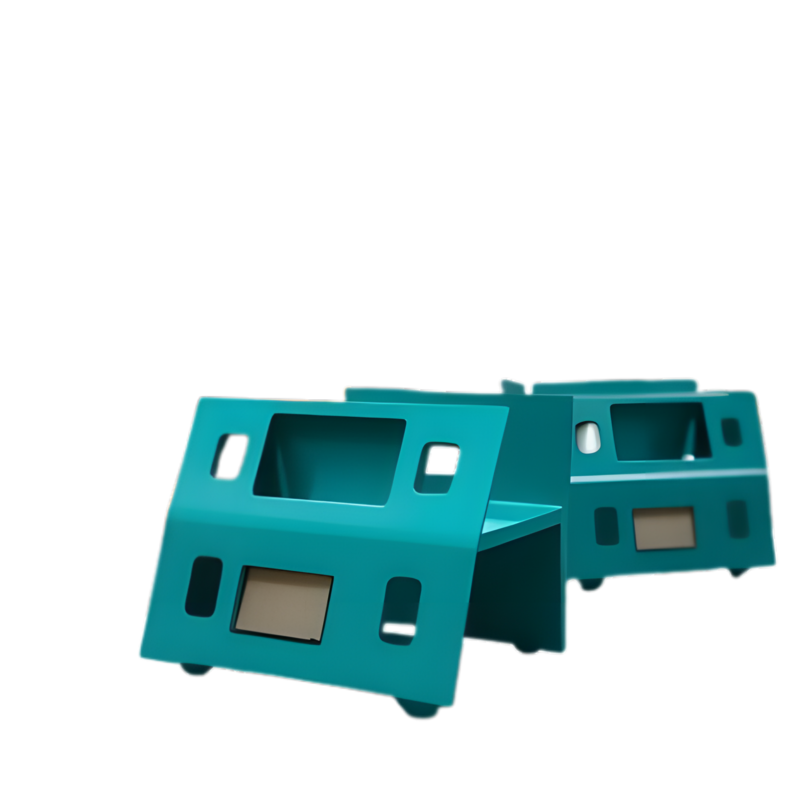

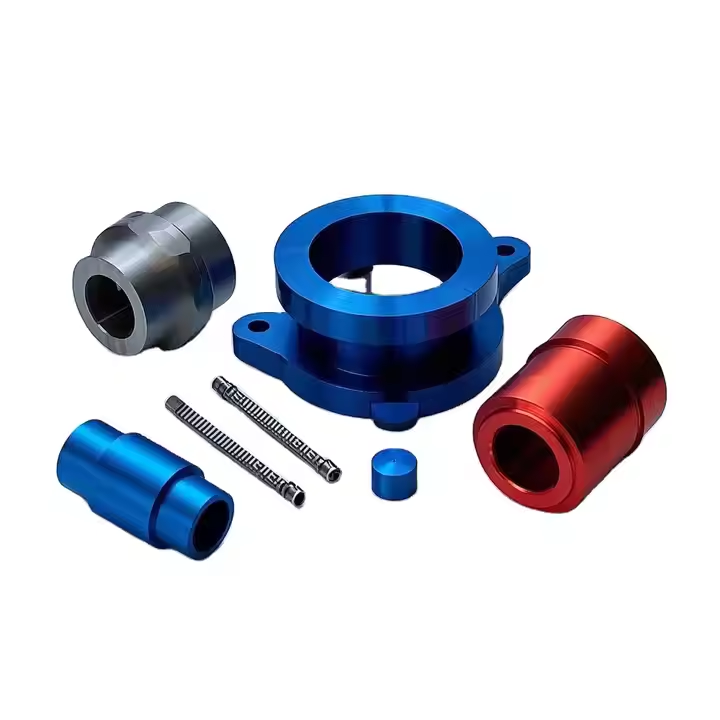

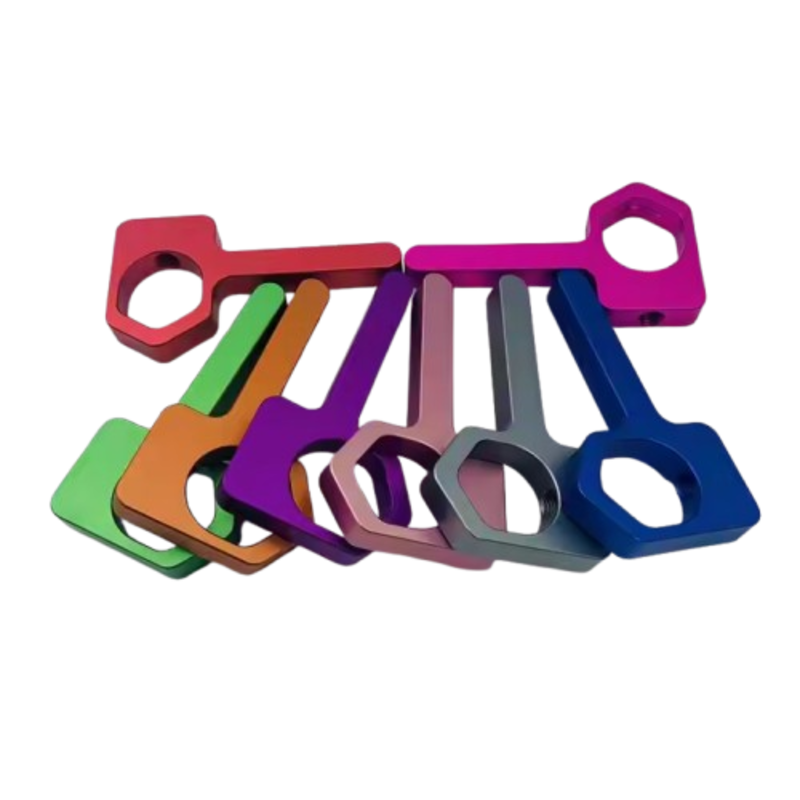

Product Showcase

|

|

|

|

Product parameters

| Parameter | Specification |

| Base Materials | Aluminum, Magnesium, Titanium, Zinc alloys |

| Surface Finish | Matte, Satin, Glossy, Textured |

| Max Workpiece Size | Up to 2.5m x 1.5m x 1.5m (custom sizes on request) |

| Spray Coating Type | Epoxy, Polyurethane, Fluoropolymer, Powder Coating |

| Color Options | Clear, Black, Bronze, Gold, Red, Blue, Custom Pantone |

| Adhesion Strength | ≥ 5B (ASTM D3359 standard |

| Hardness | Up to 200–300 HV (depends on coating type; lower than anodizing) |

| Corrosion Resistance | ≥ 336 hours (ASTM B117 Salt Spray Test; varies with coating system) |

| Temperature Resistance | Up to 200°C (depending on coating formulation) |

| Environmental Compliance | RoHS, REACH, Low-VOC coatings available |

Custom Process

CONTACT

NEGOTIATION

SENT SAMPLE

TRANSPORTATION

Quality Control

Our Spray Surface Treatment service is supported by a rigorous Quality Control (QC) process to ensure consistent coating performance, durability, and visual quality across every production batch.

Incoming Material Inspection

All base metals are verified for alloy composition, surface integrity, and cleanliness prior to spray coating.

Surface pre-treatment (e.g., degreasing, sandblasting, or chemical etching) is inspected to ensure optimal coating adhesion.

In-Process Quality Checks

Spray parameters (e.g., gun pressure, distance, spray angle, and environment conditions) are monitored and controlled in real time.

Cure cycle parameters (oven temperature, time) are validated to ensure complete cross-linking of coating materials.

Cleanroom or dust-controlled environments used where required to prevent contamination of coated surfaces.

Post-Treatment Inspection

Adhesion testing (ASTM D3359 – Cross Hatch or Pull-Off Test)

Coating thickness verification (ASTM D7091 using magnetic or eddy current gauges)

Color matching and gloss level verification per customer or Pantone specification

Salt spray corrosion test (ASTM B117) on representative samples for durability assessment

Surface appearance check for uniformity, defects (e.g., runs, orange peel, pinholes)

Documentation & Traceability

Full batch traceability with coating parameters, inspection logs, and material lot records

Certificates of Conformance (CoC) provided upon request

Process complies with ISO 9001:2015 and relevant coating standards (e.g., ISO 12944, ASTM standards)

Continuous Improvement

QC team collaborates with production and R&D to:

Implement lean and Six Sigma practices

Reduce coating defects and rework

Improve coating performance based on feedback, testing, and benchmarking

FAQ

1. What materials are suitable for spray surface treatment?

Answer:

Spray coating can be applied to a wide range of metals, including aluminum, magnesium, titanium, zinc alloys, and steel. Proper surface preparation (e.g., cleaning, degreasing, blasting) is essential to ensure adhesion and coating performance.

2. What types of coatings are available?

Answer:

We offer various types of spray coatings including:

Epoxy – Excellent chemical resistance and adhesion

Polyurethane – UV-resistant and flexible

Fluoropolymer (e.g., PTFE-based) – Non-stick and corrosion-resistant

Powder Coating – Durable, environmentally friendly, with a wide color range

3. How is coating thickness controlled and measured?

Answer:

Coating thickness is controlled by adjusting spray parameters and monitored using non-destructive gauges, in accordance with ASTM D7091. Typical thicknesses range from 30–150 µm, depending on the application.

4. What is the typical turnaround time for spray surface treatment?

Answer:

Standard turnaround time is 5–7 working days, depending on part complexity, coating type, and batch size. Expedited services may be available upon request.

5. How durable are spray coatings in terms of corrosion and wear resistance?

Answer:

Durability depends on the coating system used. Properly applied coatings can achieve:

≥ 336 hours salt spray resistance (ASTM B117)

Good impact and abrasion resistance

Temperature tolerance up to 200°C

For enhanced protection, multi-layer primer/topcoat systems can be used.