Product Description

Our Stamping Die and Progressive Press Stamping Services offer high-precision sheet metal part manufacturing through advanced tooling and automation. Utilizing progressive dies in high-speed stamping presses, we deliver complex, multi-stage metal parts with tight tolerances and consistent quality. This solution is ideal for high-volume production across various industries, including automotive, electronics, appliances, and industrial equipment.

Each stamping die is custom-engineered for the client’s part specifications, ensuring optimal material usage, efficient cycle times, and reliable repeatability. With in-house tool design, die maintenance, and quality control, we provide a complete turnkey solution from prototyping to mass production.

Key Highlights

| Progressive Die Stamping | Multiple forming operations (blanking, piercing, bending, coining) performed in a single press stroke for high efficiency and consistency. |

| Custom Tooling Design | Dies are designed and manufactured in-house using CAD/CAM to meet exact part geometry and production needs. |

| Material Flexibility | Compatible with a wide range of metals including carbon steel, stainless steel, aluminum, copper, and brass. |

| Tight Tolerance Capability | Up to ±0.01 mm, depending on part and material. |

| Scalable Production | Suitable for both prototype development and high-volume runs. |

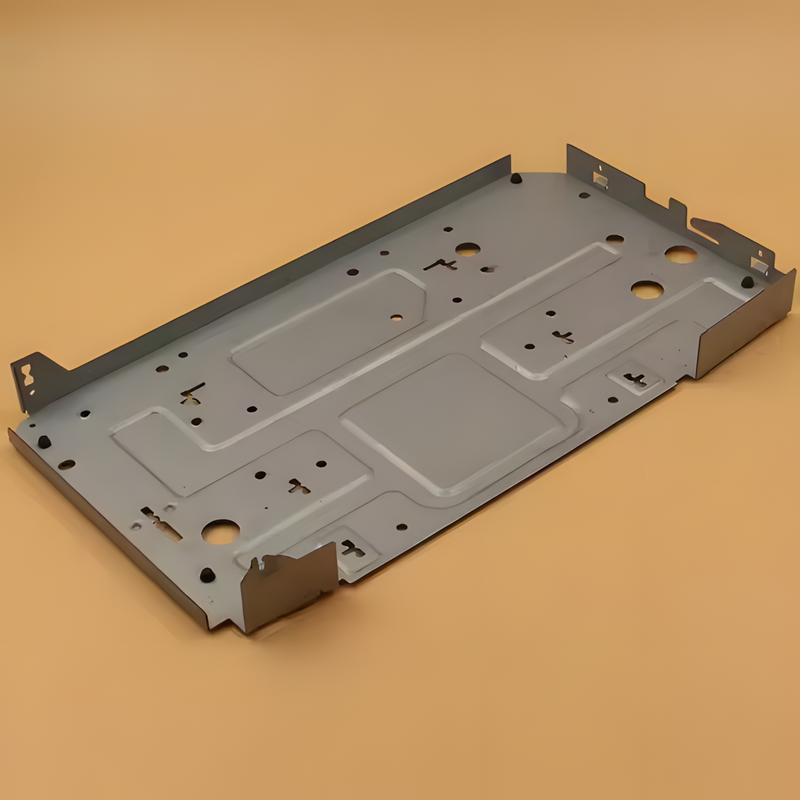

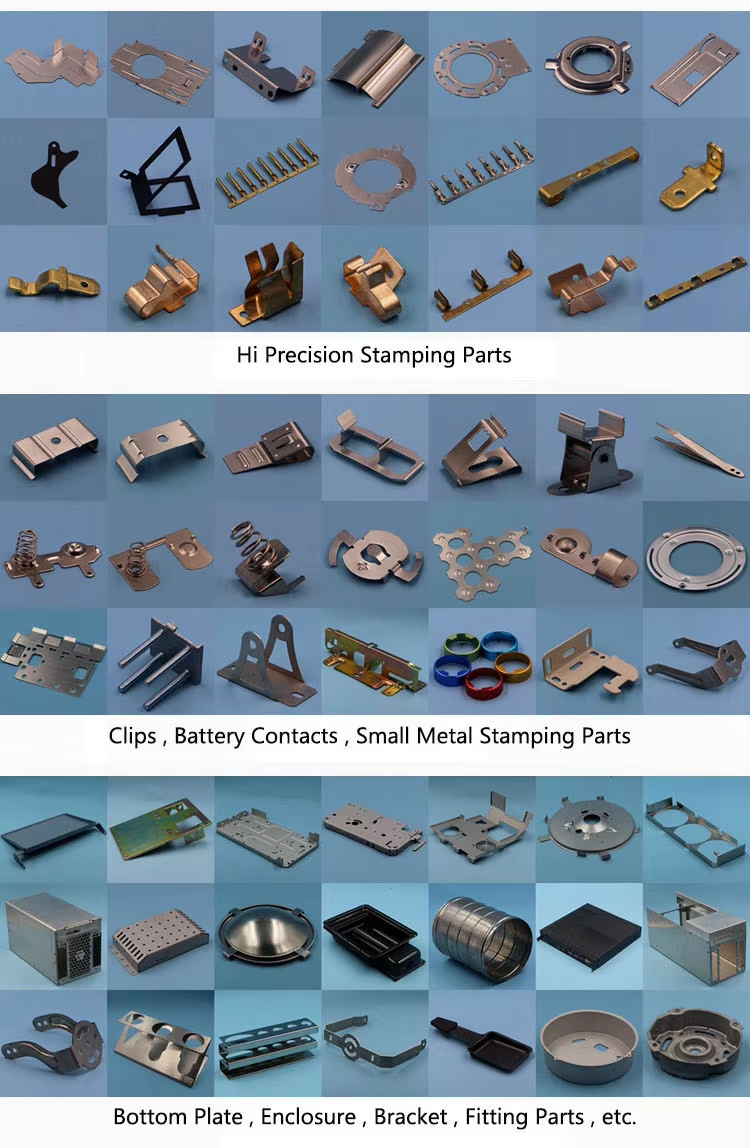

Product Display

Application

AUTOMOTIVES |

ROBOTICS |

AERODYNAMIC |

INDUSTRIAL |

Power equipment ,New energy, Electronic equipment, Household items, Medical industry

Why Choose Us?

Over 10 years of experience in precision metal stamping

In-house tooling design and manufacturing

ISO-certified quality control systems

Fast lead times and responsive technical support

Product parameters

| Parameter | Details | Parameter | Details |

| Product Name | Customizable Stamping Die Sheet Metal Progressive Press Stamping Parts | Production Capacity | Up to 1,000,000 pieces/month (depending on part size and complexity) |

| Process Type | Progressive Die Stamping | Lead Time | 7–25 days (based on order quantity and customization) |

| Material Options | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, or Custom | Quality Standard | ISO 9001:2015 / IATF 16949 (optional for automotive) |

| Material Thickness | 0.2 mm – 6.0 mm | Design Support | CAD/3D Models, Prototyping, Reverse Engineering Available |

| Tolerance | ±0.01 mm (varies based on design and material) | MOQ (Minimum Order) | Varies by part complexity; typically 1,000 pcs |

| Surface Treatment | Zinc Plating, Nickel Plating, Chrome Plating, Anodizing, Powder Coating, Polishing | Packaging | Cartons, Pallets, or Custom Packaging Available |

| Tooling Type | Custom Progressive Die | Application Industries | Automotive, Electronics, HVAC, Home Appliances, Machinery, Aerospace |

Custom Process

Contact customer service Confirm specifications Place order and make payment

Confirm receipt of goods Factory delivery Custom processing

Quality Control

We implement a strict and comprehensive quality control system throughout every stage of production to ensure our sheet metal progressive stamping parts meet or exceed customer expectations.

| Stage | Inspection Method | Purpose |

| Incoming Material Check | Raw material certification, thickness and hardness testing | Ensure material conforms to specifications |

| Tooling Inspection | Die dimension verification, test stamping | Validate accuracy of progressive die before production |

| In-Process Inspection | First article inspection, real-time sampling, SPC monitoring | Detect defects early, ensure consistency during stamping |

| Dimensional Check | Calipers, micrometers, height gauges, CMM (if required) | Verify precision tolerances are met |

| Surface Quality Check | Visual inspection, coating thickness test, salt spray test | Confirm surface treatment quality and appearance |

| Final Inspection | Full batch inspection, customer-specific checklists | Ensure finished products meet client requirements |

| Packaging Inspection | Quantity verification, packaging integrity check | Prevent damage during transportation |

Factory Real shot

Die Processing Workshop,Die Asseblly Workshop,Stamping Workshop,Ultrasonic Cleaning Line,Laser Cutting Machine,CNC Bending Machine

FAQ

Q: Do you sell ready-made products?

A: No, we don’t sell spot goods. We only customize non-standard metal parts.

Q: What information is required for an inquiry?

A: To give an accurate quotation, we need detailed information such as drawings, pictures, physical samples, quantity needed, and other specific requirements of the product.

Q: Can I get a sample for metal stamping parts?

A: Yes, we can prototype samples in a simple way before mass production.

Q: What is your payment term?

A: Deposit plus balance payment. The payment should be settled before shipment.