Product Description

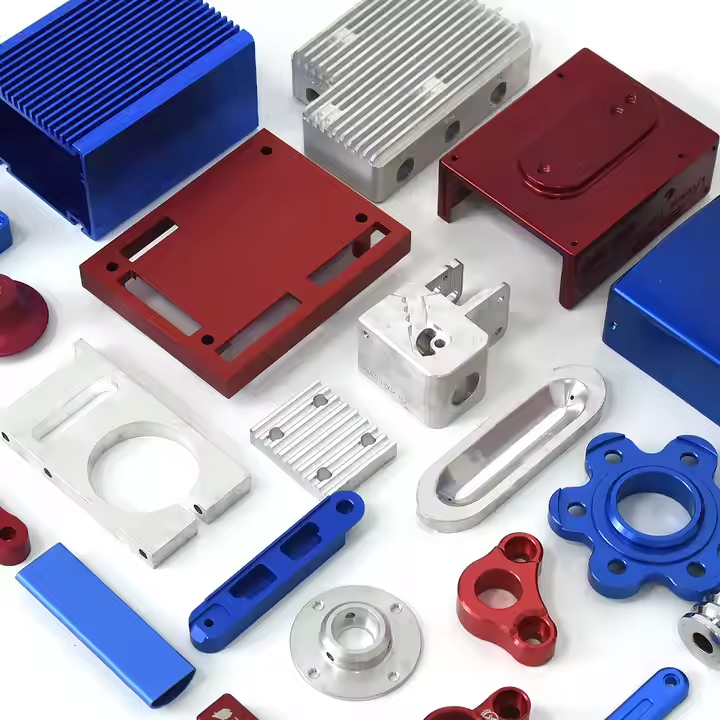

This spray surface treatment enclosure highlight

Surface treatment service with a focus on professional spray coating. Designed to enhance both protection and appearance, the enclosure features a clean, uniform finish that improves durability and offers a refined, modern look. It ensures excellent heat dissipation, corrosion resistance, and long-term reliability — making it an ideal solution for custom electronic housings, control boxes, and various industrial electronics applications.

Factory Strengths & Service Highlights

Your Trusted Partner for Professional Surface Treatment Solutions

1. Professional Expertise & Skilled Team

Over 10 years of experience in surface finishing and spray coating, with a dedicated team of engineers and quality controllers.

2. Full Customization Capability

Spray coating processing is a key method in non-standard manufacturing to achieve surface protection

3. Advanced Equipment & Quality Control

Equipped with modern spray booths, ovens, and inspection tools. Each product undergoes strict quality checks before delivery.

4. Stable Production & On-Time Delivery

Efficient production system ensures fast lead times and consistent output — suitable for both small batch and large-scale projects.

5. Responsive Customer Service

Friendly, multilingual support team ready to assist you from design consultation to after-sales service.

Functional Features

|

|

|

| Surface Protection | Provides durable coatings that resist corrosion, abrasion, moisture, and UV exposure, extending the service life of components in harsh environments. |

| Aesthetic Enhancement | Offers a wide range of color options, gloss levels, and surface textures (e.g., matte, high-gloss, metallic), allowing precise visual customization for product branding and appeal. |

| Material Versatility | Compatible with metals, plastics, composites, and engineered surfaces, ensuring consistent adhesion and performance across different substrates. |

| Application Flexibility | Supports small-batch customizations to large-scale industrial production, with adjustable spray processes tailored to product shape, complexity, and usage environment. |

| Functional Finishes | Enables special surface properties such as anti-fingerprint, soft-touch, high hardness, or electrostatic resistance — critical for electronic and high-touch products. |

| Environmental Adaptability | Offers eco-friendly formulations and energy-efficient curing options (e.g., UV curing), meeting industrial standards for sustainability and compliance. |

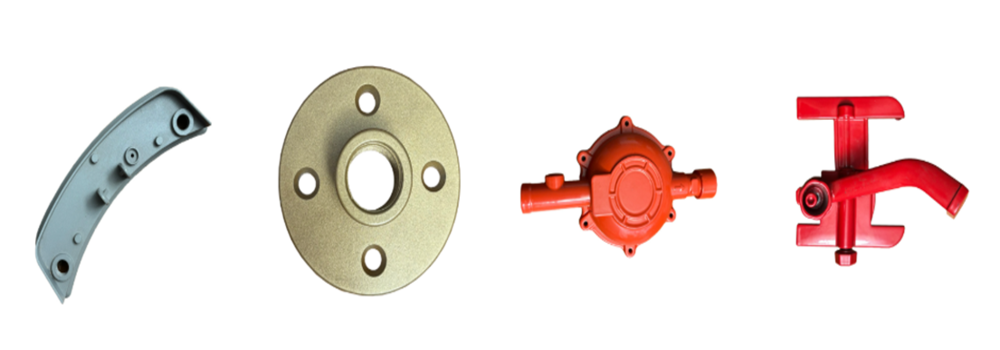

Application

| Agricultural | Outer box baking paint | Auto parts | Various casing shells | Household electrical |

| Building materials | Metal brackets | Drones | Balance scooters | Plastic toys |

Product parameters

Parameter | Description |

Material Type | Aluminum alloy, stainless steel, plastic, or other specified substrates |

Product Dimensions | Overall size, thickness, and surface area to be coated |

Surface Preparation | Options include degreasing, sandblasting, or etching (if required) |

Coating Type | Polyurethane, epoxy, acrylic, or other specified spray materials |

Finish Type | Glossy, matte, semi-gloss, or textured finish |

Color | Standard RAL or Pantone colors, or custom color matching |

Coating Thickness | Typically 10–30 microns (can be adjusted based on requirement) |

Packaging Method | Individual wrap, foam insert, or bulk packaging as specified |

Information requested from customers

Information Type | Details |

1. Design Files | Supported formats: STEP, IGS/IGES, STL, DWG, PDF, or high-resolution image with dimensions |

2. Quantity Requirements | Total number of units to be processed (including prototype or mass production) |

3. Material and Tolerance Specs | Specify base material (e.g., aluminum alloy) and required dimensional tolerance |

4. Surface Treatment Details | Type of spray coating, desired finish (e.g., glossy/matte), and color code (RAL/Pantone) |

5. Special Processing Instructions | Any specific notes such as threaded sections, masked areas, surface roughness, etc. |

Custom Process

Requirement Consultation

Drawing or Sample Submission

Coating Method Selection

Color & Texture Confirmation

Sample Production

Surface Preparation

Spray Coating & Curing

Final Inspection & Delivery

Quality Control Process

01 Order ConfirmationCustomer Requirement Confirmation: Discuss requirements and quality standards, ensuring every detail is considered. Technical Evaluation and Confirmation:Evaluate drawings and technical requirements, confirm feasibility, and develop a quality control plan. | 02 Incoming InspectionSupplier Selection and Evaluation: Choose qualified raw material suppliers to ensure supply chain stability and material quality. Incoming Material Inspection:Strictly test the chemical composition and mechanical properties of raw materials to meet standards. | 03 In-Process ControlProcess Planning and First Part Inspection: Develop process flow and thoroughly inspect the first article’s dimensions, shape, surface, and performance. Process Monitoring and Statistical Process Control:Monitor production data in real-time, implement SPC, and ensure production stability and quality consistency. |

04 Final InspectionFinal inspection: Final inspection of finished products to ensure that the size and performance meet the standards. Packaging and compliance inspection:Develop and implement packaging specifications to ensure transportation safety. | 05 DeliveryPre-shipment Inspection: The quality technician performs random checks to ensure high product quality. Shipping Preparation:Customer representative confirms shipping details to ensure timely and safe delivery. | 06 Consistent UpgradingCustomer Feedback Handling: Collect and address customer feedback and complaints. Quality Improvement:Analyze feedback and data, implement improvements, and enhance quality and satisfaction. |

|

|

|

|

2.5D Measuring Instrument | Coordinate Measuring Machine | Salt Spray Test Machine | UV Resistance Testing Equipment |

|

|

|

|

| Rockwell Hardness Tester | Color Difference Meter Tester | Digital Roughness Tester | Coating Thickness Gauge |

Company Display

| Office corner | Vacuum plating machine | Incoming materials inspection area |

| Vacuum plating furnace | IQC quality inspection area | Spray coating operation area |

| Automatic spray coating line | Finished product storage area | Performance testing area |

After-Sales Guarantee

Focus on the stability of non-standard processes, eliminating concerns with professional after-sales service, ensuring every product remains glossy and durable.

All products undergo strict inspection before shipment. Minor imperfections that do not affect functionality are not quality issues; your understanding is appreciated. Our products are rigorously quality-checked before shipping. Please inspect carefully upon receipt and contact us promptly if there are any issues. For quality problems, please provide product photos to our online customer service. After confirmation, we will cover return shipping costs. Returns due to non-quality issues require the buyer to bear shipping costs. Thank you for your understanding.