Product Description

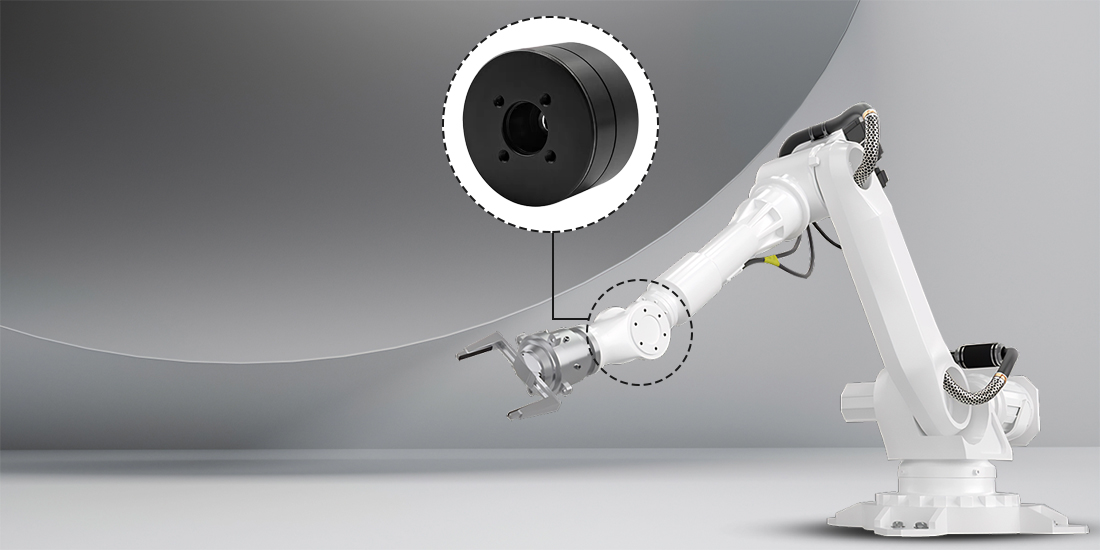

4Nm direct drive joint motor, high torque, zero backlash, fast response, integrated encoder, suitable for robots and automation equipment, accurate and reliable

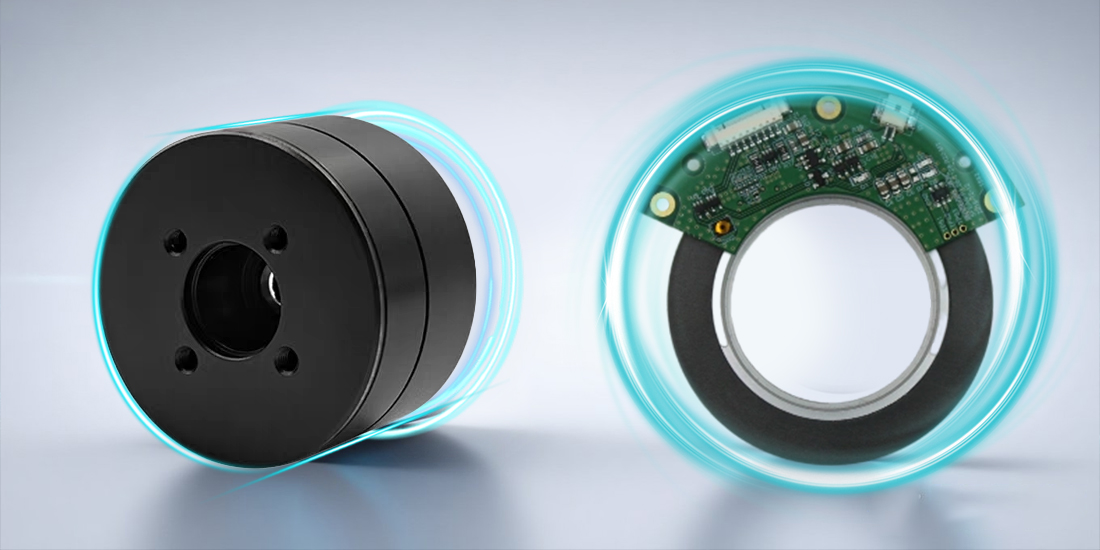

Compact structure, light weight

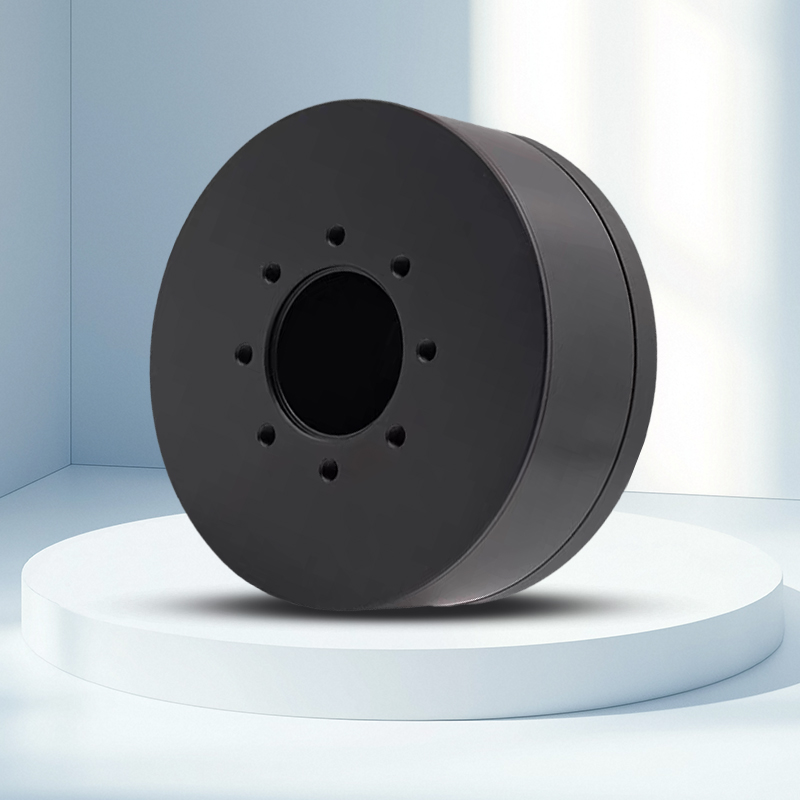

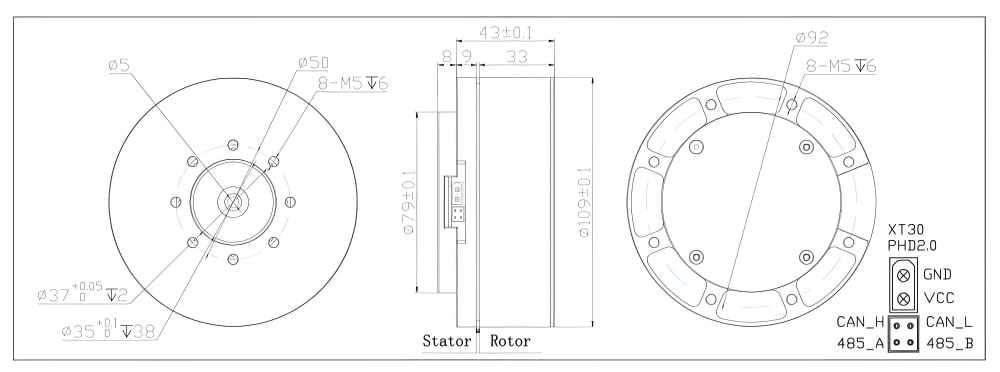

Height 43 mm, diameter 109 mm, weight 1028g

Features

This direct drive rotor adopts a low-inertia design.

Achieve millisecond-level response

and ultra-high acceleration performance.

Ultra-high-resolution single-turn absolute encoder to achieve precise positioning

Product parameters

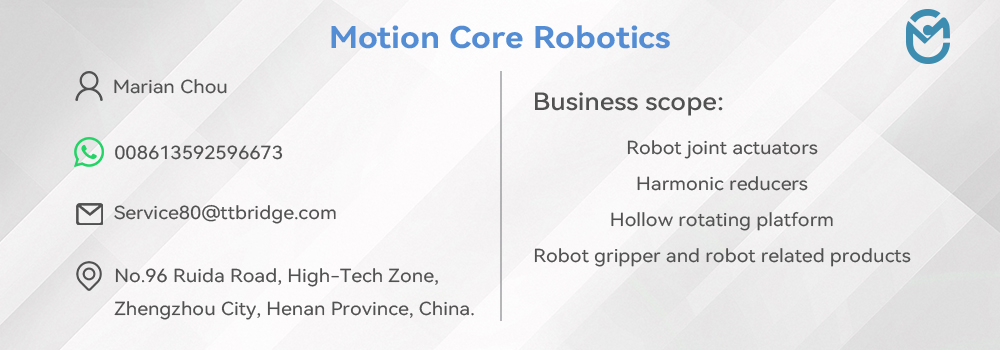

Parameters | Unit | DD4006-7 | DD5010-10 | DD6015-6 | DD7010-2 | DD7010-11 | DD8015-2 | DD9015-1 | DD9015-4 | DD11025-3 |

Nominal voltage | V | 12 | 24 | 24 | 24 | 36 | 24 | 24 | 36 | 36 |

Voltage range | V | 10~28 | 10~28 | 12~40 | 12~40 | 12~40 | 12~40 | 12~40 | 12~40 | 12~40 |

Nominal current | A | 1.1 | 0.9 | 1.6 | 3.1 | 1.3 | 2.9 | 5.8 | 2.1 | 3.8 |

Nominal power | W | 13.2 | 21.6 | 38.4 | 74.4 | 46.8 | 69.6 | 139.2 | 75.6 | 136.8 |

Nominal torque | N.M | 0.09 | 0.2 | 0.65 | 0.8 | 0.8 | 1.2 | 1.1 | 1.26 | 4 |

Nominal speed | RPM | 467 | 504 | 264 | 618 | 294 | 354 | 954 | 372 | 168 |

No-load max speed | RPM | 1412 | 828 | 558 | 924 | 564 | 516 | 1146 | 534 | 330 |

Peak torque | N.M | 0.15 | 0.49 | 1.26 | 1.93 | 1.59 | 3.7 | 5.17 | 4.11 | 8.5 |

Peak current | A | 1.9 | 1.9 | 3.2 | 16 | 2.7 | 16 | 33.1 | 6.6 | 16 |

Speed constant | rpm/v | 117 | 34.4 | 23.3 | 38.5 | 15.5 | 21.5 | 47.8 | 14.8 | 9.2 |

Torque constant | N.M/A | 0.08 | 0.23 | 0.43 | 0.22 | 0.61 | 0.41 | 0.19 | 0.67 | 1.03 |

Rotor inertia | gcm² | 65 | 195 | 504 | 672 | 672 | 1555 | 2574 | 2574 | 7796 |

Number of pole pairs | Pairs | 11 | 14 | 14 | 14 | 14 | 21 | 21 | 21 | 21 |

Phase resistance | Ω | 3.17 | 5.16 | 5.77 | 0.83 | 5.29 | 1 | 0.33 | 3.89 | 1.5 |

Phase inductance | mH | 0.54 | 1.63 | 3.82 | 0.68 | 3.68 | 0.63 | 0.23 | 3.14 | 1.13 |

Motor weight | g | 70 | 134 | 251 | 261 | 261 | 418 | 534 | 534 | 1028 |

Communication | / | RS485/CAN | ||||||||

Encoder type | / | Single turn absolute value | ||||||||

Resolution | bit | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

Working temperature | ℃ | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 | -20~80 |

ID of encoder magnetic steel) | mm | Ø5 | Ø5 | Ø5 | Ø5 | Ø5 | Ø5 | Ø5 | Ø5 | Ø5 |

Motor size | mm | Ø40*24*Ø12.6 | Ø49*29*Ø12.6 | Ø60*34*Ø22 | Ø68*31*Ø22 | Ø68*31*Ø22 | Ø79*36*Ø35 | Ø89*38*Ø35 | Ø89*38*Ø35 | Ø109*51*Ø35 |

DD11025

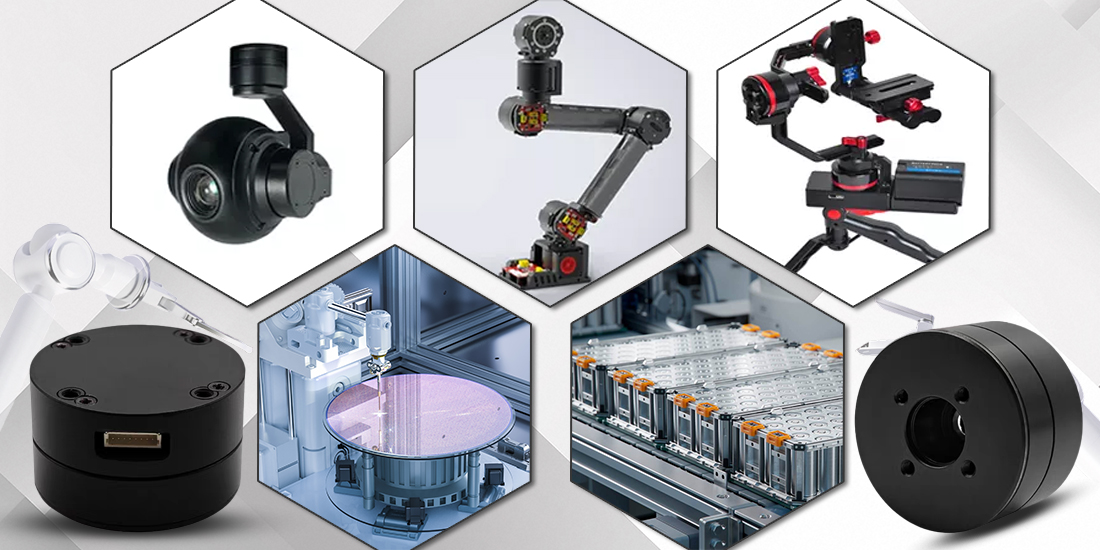

Application

The 4Nm direct-drive joint motor is used in high-precision direct drive scenarios such as collaborative robots, precision turntables, and medical equipment, and has zero backlash and high response characteristics.

Note

1. Do not disassemble the motor privately;

2. All interfaces do not support hot plugging. You need to plug in the wires before powering on.

At the same time, the ground wire of the control signal needs to be connected;

3. The motor is not allowed to suddenly stall during high-speed operation;

4. Do not use overvoltage;

5. Monitor the motor temperature in time, and make the motor work in a reasonable temperature range by reducing power or increasing heat dissipation;

6. Before installing the device, it is recommended to use the host computer to debug the same working conditions first;

7. Update the firmware in time to obtain better motor performance.

Contact Us