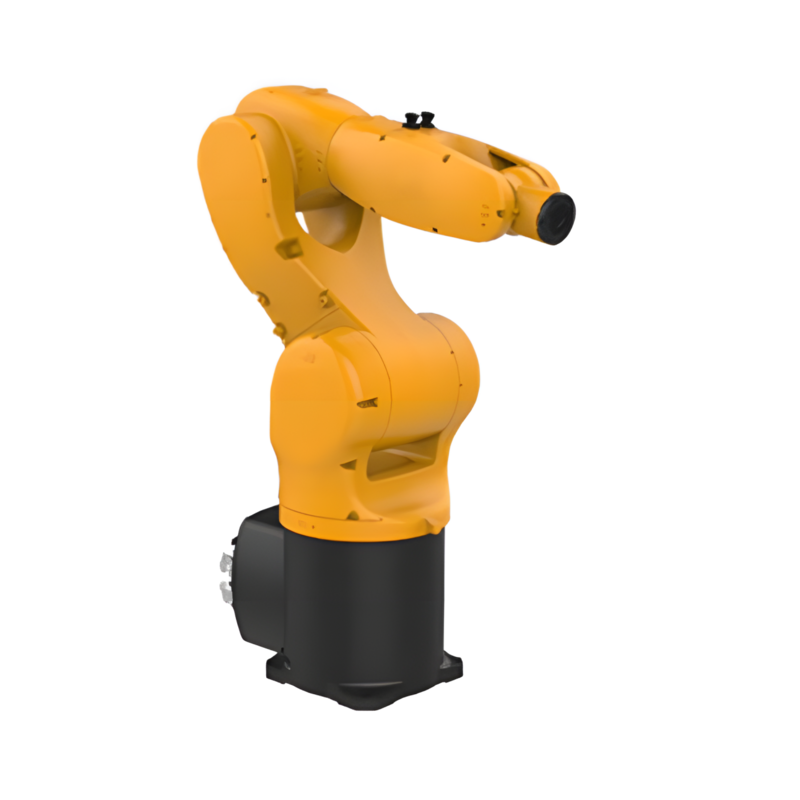

Deskripsi Produk

FlexiArm R3 adalah lengan robot industri berperforma tinggi dan ringan yang dirancang untuk fleksibilitas, presisi, dan kecepatan dalam proses manufaktur modern. Dengan kapasitas payload 3kg, robot ini dioptimalkan untuk tugas seperti penanganan material, pengelasan, penggerindaan, dan perakitan, khususnya di industri seperti elektronik, otomotif, pengolahan makanan, dan pemrosesan logam.

Meskipun berukuran kompak, FlexiArm R3 menawarkan kekuatan dan presisi yang luar biasa. Desain fleksibelnya memungkinkan pengendalian multi-sumbu, pemasangan cepat, dan pemrograman yang mudah, menjadikannya pilihan ideal untuk meningkatkan konsistensi produksi, menurunkan biaya tenaga kerja, dan meningkatkan efisiensi operasional.

Skenario Aplikasi

| Industri | Contoh Aplikasi |

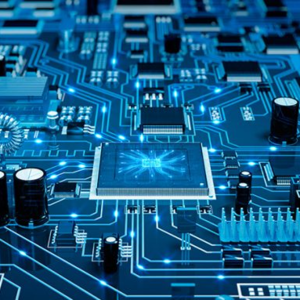

| 3C (Komputer, Komunikasi, Elektronik Konsumen) | Penanganan PCB, pemasangan sekrup, perakitan, penyolderan presisi |

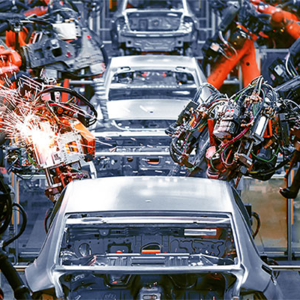

| Otomotif | Pemindahan komponen, aplikasi sealant, inspeksi |

| Energi Baru | Penanganan sel baterai, perakitan panel, pengepakan modul |

| Kimia | Pengambilan botol, pemasangan tutup, penanganan bahan berbahaya |

| Manufaktur Kaca | Pemolesan, penggerindaan tepi, pemindahan bagian kaca |

| Pengolahan Makanan | Penyortiran, pick and place, pengepakan |

| Pemrosesan Logam | Pengelasan, pemotongan, penggerindaan |

| Karet & Plastik | Pemangkasan hasil injeksi, penyortiran komponen, penghilangan gerigi |

| Mesin Konstruksi | Penanganan komponen, pemasangan baut, pergantian alat |

Fitur Produk

Desain Kompak & Ringan dengan Kapasitas 3kg

Meskipun memiliki jejak yang kecil, FlexiArm R3 memberikan presisi dan stabilitas tinggi—ideal untuk ruang kerja terbatas dan aplikasi yang membutuhkan penanganan komponen kecil atau siklus kerja cepat.

Manfaat: Hemat ruang, hemat energi, dan mudah diintegrasikan ke lini produksi yang ada.

Contoh Penggunaan: Perakitan komponen kecil, penanganan elektronik, otomasi presisi.

ompatibel Multi-Fungsi & Integrasi Plug-and-Play

FlexiArm R3 mendukung berbagai jenis end-effector seperti gripper, suction cup, torch pengelasan, dan alat penghalus. Didesain untuk pemasangan cepat dan integrasi lancar dengan perangkat lunak pihak ketiga serta sistem penglihatan mesin.

Manfaat: Mengurangi waktu setup, meminimalisasi downtime, dan mudah dialihfungsikan.

Contoh Penggunaan: Perubahan lini produksi cepat, inspeksi berbasis AI, lini produk campuran.

Parameter produk

| Spesifikasi | Detail |

| Model | FlexiArm R3 |

| Kapasitas Payload | 3 kg |

| Radius Jangkauan | ±650 mm (dapat disesuaikan) |

| Jumlah Sumbu (DOF) | 6 |

| Repeatability | ±0.02 mm |

| Kecepatan Maksimum | 2.5 m/s |

| Opsi Pemasangan | Lantai, dinding, langit-langit |

| Sumber Daya | AC 220V / 50Hz |

| Metode Kontrol | Teach pendant / PC / API |

| Protokol Komunikasi | Modbus, Ethernet/IP, RS485 |

| Lingkungan Operasional | 0–45°C, Kelembapan < 85% |

| Rating IP | IP54 (opsional IP65) |

| Berat Unit | ±17 kg |

Kasus Pelanggan

Manufaktur Elektronik (3C)

Pengelasan Komponen Otomotif

Penyortiran Makanan di Jalur Produksi

Pertanyaan yang Sering Diajukan

| Question | Answer |

| Apakah robot ini bisa diintegrasikan dengan sistem kamera atau AI? | Ya, FlexiArm R3 mendukung integrasi dengan kamera industri dan sistem penglihatan berbasis AI untuk pengenalan objek dan inspeksi otomatis. |

| Berapa umur operasional robot ini? | Dengan perawatan rutin, FlexiArm R3 dapat beroperasi selama lebih dari 30.000 jam, tergantung pada beban kerja dan kondisi lingkungan. |

| Apakah perlu pelatihan khusus untuk mengoperasikan robot ini? | Tidak perlu pelatihan rumit. FlexiArm R3 dilengkapi antarmuka pengguna yang intuitif. Kami juga menyediakan pelatihan online dan langsung di lokasi. |

| Apa jenis end-effector yang kompatibel? | Kompatibel dengan gripper (elektrik/pneumatik), suction cup, torch pengelasan, alat trimming, dan tool kustom lainnya melalui flensa ISO standar. |

| Apakah robot ini bisa digunakan di ruang bersih atau lingkungan makanan? | Ya, dengan bahan bersertifikasi food-grade dan opsi penyegelan IP khusus, robot ini cocok digunakan di lingkungan yang higienis seperti dapur industri atau ruang bersih. |