Product Description

ABS/PC Plastic UV Vacuum Coating Process

The ABS/PC plastic UV vacuum coating process combines UV curing technology with vacuum coating technology. It is mainly used for electrical product accessories, decorative parts, toys, gifts, daily necessities, cosmetics, and other surfaces to form a coating that offers both a metallic texture and high protection. Any plastic surface that requires beautification can be achieved!

Plated Parts for Various Products

The plated parts can be used for various products such as: power bank cases, wireless Bluetooth earphones, wired earphones, electric toothbrush handles, beauty device buttons, RF device decorative parts, eye massagers, facial cleansing device parts, fascia guns, rice cooker buttons, water heaters, keyboard shells, mouse shells, desk lamps, chandeliers, spotlights, reflector cups, makeup brush handles, paintbrush handles, gold foil branches, lipstick cases, eyeshadow palettes, eyebrow pencil barrels, eyeliner bottles, lip balm containers, skincare product caps, electronic pens, ballpoint pens, phone cases, combs, mirrors, keychains, car decoration accessories, key protectors, children’s watch cases, watch protectors, toy accessories, toy car wheel hubs, voice recorder buttons, projector accessories, drawer handles, suitcase handles, collectible dolls, clothing decoration accessories, and more.

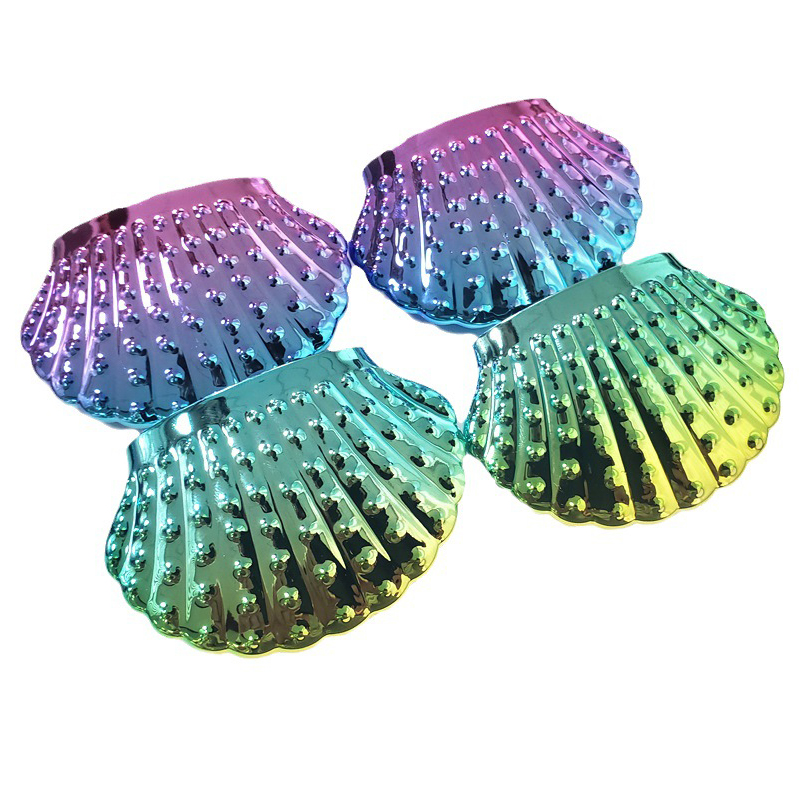

Example

Functional Features

Plastic UV Vacuum Coating

Bright colors Stable performance Rust-resistant surface

| Features of Vacuum Coating |

Special Notes:

Mold opening, injection molding, and plating processing can be integrated with customer cooperation for one-step forming of plastic parts.

All product quotations are based on actual samples.

Plastic product dimensions that can be processed: within 2440mm x 1200mm.

Various surface treatment effects for plastic products can be customized according to customer requirements. Please provide size specifications, material, and sample reference when requesting a quote.

Product parameters

| Item | Parameter | Item | Parameter |

| Process | UV Vacuum Coating | Treatment Type | Plastic Surface Treatment |

| Product Name | Plastic Shell Plating Processing | Product Color | Customizable upon request |

| Material | ABS/PC | Product Size | Customizable |

| Product Size | Various customizable sizes | Product Features | Bright gloss / delicate texture |

Customization Process

| Communicate requirements | Confirm style | Place order and make paymen | Mass production |

| After-Sales Service | Positive reviews upon receipt | On-time delivery | Final payment |

Process Stages and Key Steps

| Stage | Core Steps | Key Role | Main Parameters / Methods |

| Pre-treatment | 1. Degreasing and Cleaning | Remove oil, mold release agents, and | Ultrasonic / spray cleaning, 40-60°C |

| 2. Surface Activation | Improve surface tension of low surface energy | Plasma treatment / flame treatment | |

| 3. Drying | Completely remove moisture to ensure | Hot air drying at 60-80°C, | |

| Primer Coating | 1. Spray UV Primer | Fill substrate defects, provide smooth base, | Film thickness 5-15μm, automatic spray / electrostatic spray |

| 2. UV Pre-curing | Partially cure primer (70%-80%), | UV lamp (365 nm), energy | |

| Vacuum Coating | 1. Loading and | Create high vacuum environment to | Vacuum degree 1×10⁻³ - 5×10⁻⁴ Pa |

| 2. Metal Deposition (PVD) | Form metal textured coating | Thermal evaporation (Al target) or | |

| Topcoat Layer | 1. Spray UV Topcoat | Protect coating, increase hardness, | Film thickness 10-30μm, transparent |

| 2. UV Final Curing | Fully cure topcoat to form protective film | UV lamp, energy 1500-3000 mJ/cm² | |

| Post-treatment | 1. Cooling and Unloading | Prevent thermal deformation, remove parts | Natural cooling or air cooling |

2. Quality Inspection / | Ensure appearance and performance | Cross-cut test, pencil hardness test, |

Core Logic:

Ensure the substrate is clean and activated through pre-treatment → primer layer connects substrate and coating → vacuum coating achieves metallic texture → topcoat protects and enhances performance, ultimately forming a surface coating that is both beautiful and durable.

UV Iridescent Vacuum Coating Line

Mainly used for plastic electronic accessories, decorative parts, electrical accessories, toys, gifts, etc. The vacuum coating includes evaporation, sputtering, gold plating, silver plating, gunmetal color, titanium color, etc.

UV plastic vacuum coating is mainly for digital products (mobile phones, MP3 players, cameras, etc.) buttons, shells, decorative parts with UV vacuum sputtering.

Special vacuum coating includes vacuum sputtering on window lenses, panels (PC, PMMA) with different light transmittance, and vacuum coating on lighting fixtures (plastic/metal reflector cups, reflectors, etc.).

Automatic Spray Coating Line

Using brand new mechanized automatic spray coating line technology, producing more stable lines, more uniform and stable performance, and higher production capacity.

Outstanding Performance, Vacuum Environmental Protection

Fine color matching and correction, excellent adhesion resistance, specializing in plastic UV vacuum coating.

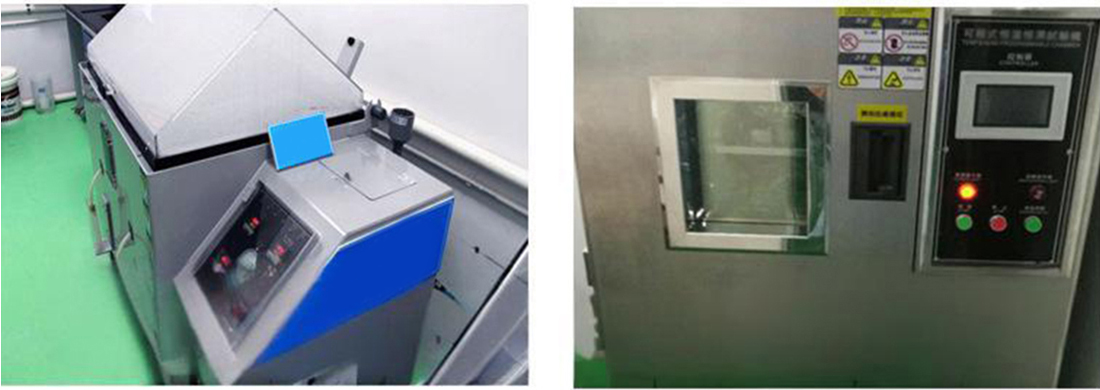

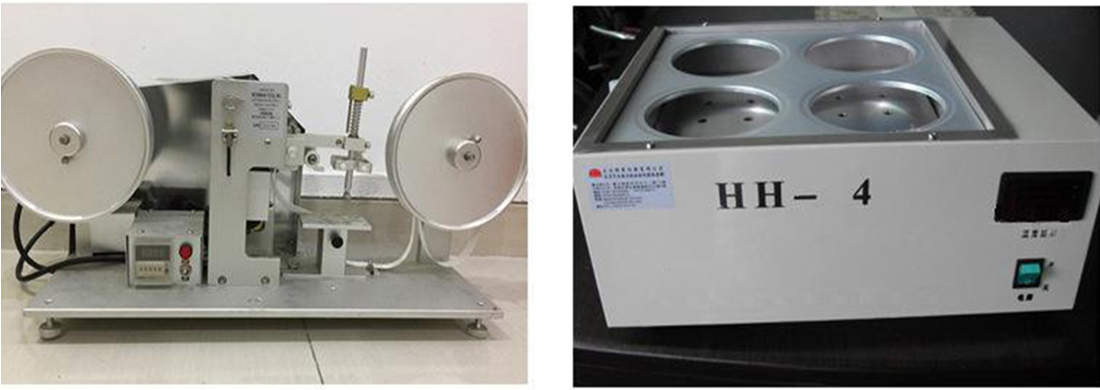

Plating Test Equipment

Professional testing instruments are crucial checkpoints for quality control, mandatory standards for surface treatment, none can be omitted.

| Salt Spray Test | Constant Temperature Test |

| RCA Abrasion Test | Cross-cut Test |

Workshop Actual Photos

| Office corner | Vacuum plating machine | Incoming materials inspection area |

| Vacuum plating furnace | IQC quality inspection area | Spray coating operation area |

| Automatic spray coating line | Finished product storage area | Performance testing area |

After-Sales Guarantee

Focus on the stability of non-standard processes, eliminating concerns with professional after-sales service, ensuring every product remains glossy and durable.

All products undergo strict inspection before shipment. Minor imperfections that do not affect functionality are not quality issues; your understanding is appreciated. Our products are rigorously quality-checked before shipping. Please inspect carefully upon receipt and contact us promptly if there are any issues. For quality problems, please provide product photos to our online customer service. After confirmation, we will cover return shipping costs. Returns due to non-quality issues require the buyer to bear shipping costs. Thank you for your understanding.