Product Description

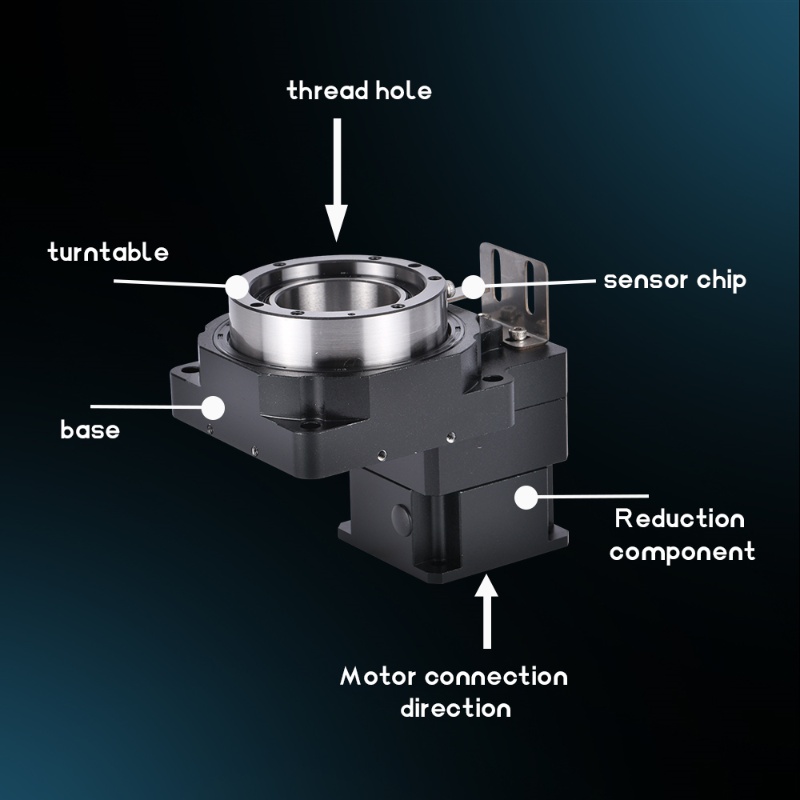

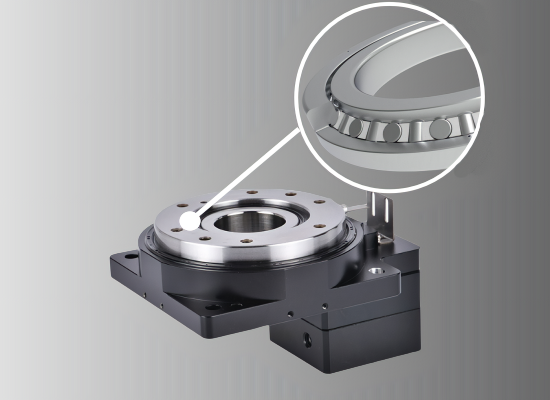

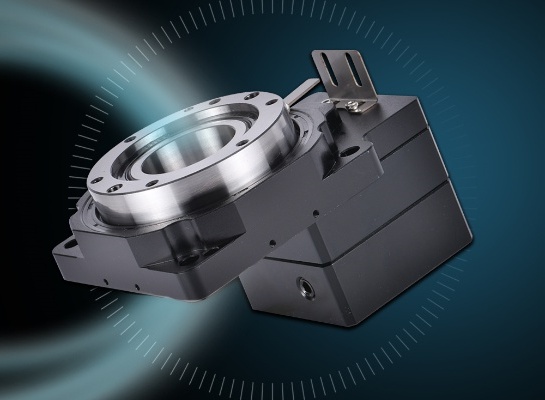

The KTN110 hollow rotary platform features a compact and lightweight design, equipped with a high-rigidity crossed roller bearing to ensure excellent radial, axial, and overturning load capacity. It offers two gear ratios (5:1 and 10:1), with a maximum permissible torque of 47 N·m and speed of up to 100 rpm. The platform achieves ±15 arcsec repeatability and has a precision lifespan of 20,000 hours. Its IP40 protection level makes it suitable for standard industrial environments. The hollow structure allows cables, air tubes, and optical fibers to pass through the center, simplifying integration. Compatible with various servo motors, KTN110 is ideal for high-precision motion applications.It has the following highlights:

1. High Positioning Accuracy – ±15 arcsec repeatability with low-backlash reduction design.

2. Hollow Shaft Design – Supports internal routing of air tubes, cables, and fibers.

3. Robust Load Capacity – Axial load up to 800N, suitable for demanding applications.

4. Flexible Motor Mounting – Compatible with various servo and stepper motor brands.

KTN110 Hollow Rotary Platform is a high-precision motion platform designed for compact, automated systems. It integrates a crossed roller bearing that provides exceptional rigidity and load-bearing performance, maintaining stability even during high-speed operation. With available gear ratios of 5:1 and 10:1, it delivers torque output of up to 47 N·m and allows a top rotational speed of 100 rpm.

The internal low-backlash gear system ensures accurate repeat positioning (±15 arcsec), making KTN110 suitable for tasks requiring precision indexing, synchronized rotation, or multi-axis motion control. The center hollow design simplifies the routing of electrical and pneumatic components, increasing system efficiency and reducing installation complexity.

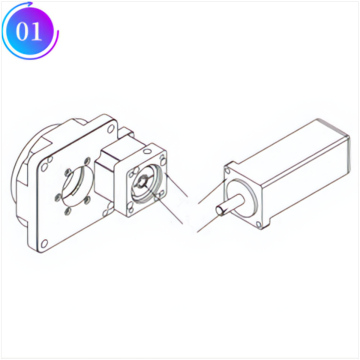

Motor Installation Instructions

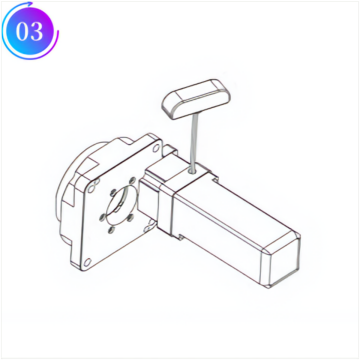

First, match the size of the motor and the hollow rotating platform and remove all foreign matter from the surface.

Remove the screw plug on the adapter flange and adjust the position until the fastening bolts can be seen.

Adjust the position of the motor and the adapter flange and gently tighten the fastening bolts. The paper locking ring will no longer rotate idly.

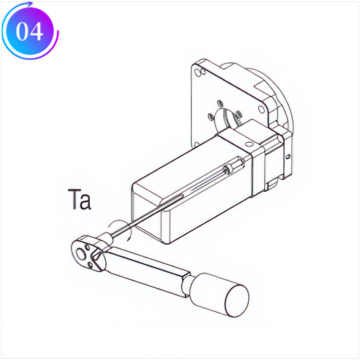

Preliminary tightening of the bolts diagonally, after completing step 5, refer to the tightening torque standard Ta and tighten the fastening bolts.

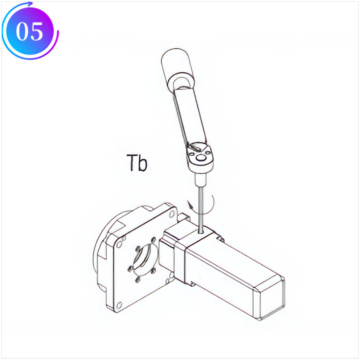

Refer to the tightening torque standard Tb and tighten the fastening bolts.

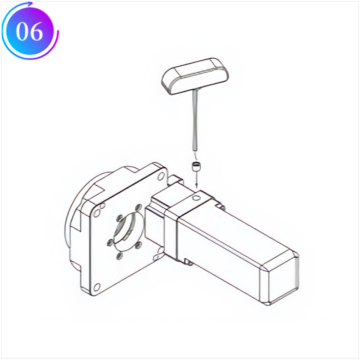

Tighten the screw plug.

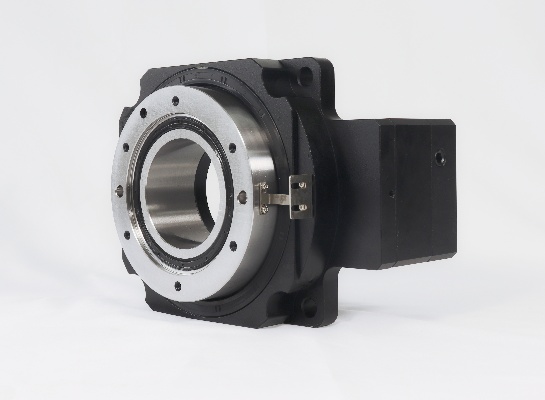

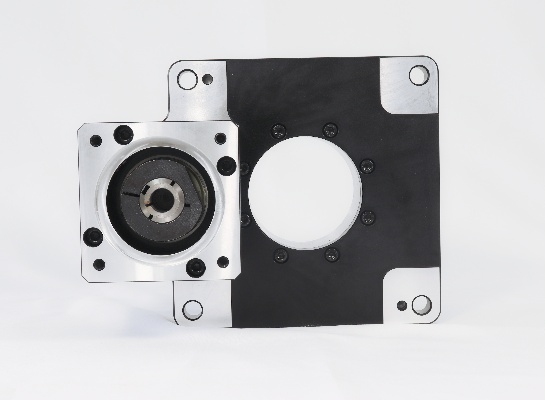

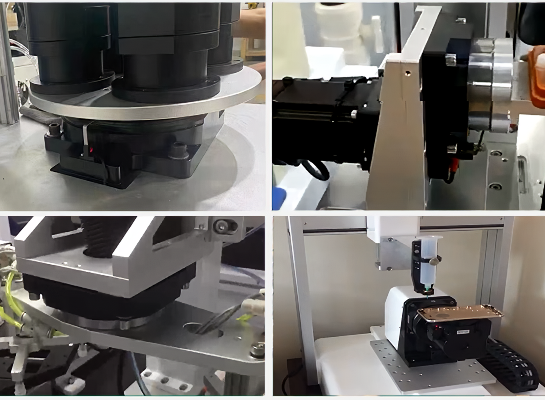

Product Display

Product parameters

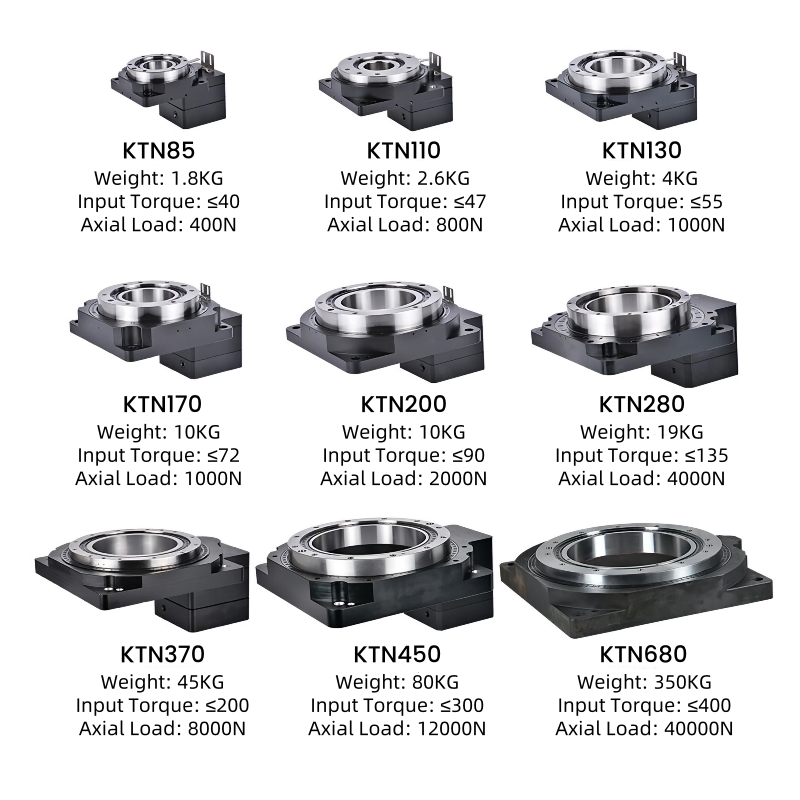

Model | KTN60-5K | KTN60-10K | KTN85-5K | KTN85-10K | KTN85-18K | KTN110-5K | KTN110-10K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:05 | 1:10 | 1:05 | 1:10 | 1:18 | 1:05 | 1:10 |

Allowable input torque(Nm) | ≤5.2 | ≤5 | ≤40 | ≤35 | ≤20 | ≤47 | ≤35 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 200 | 200 | 400 | 400 | 400 | 800 | 800 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 1.2 | 1.2 | 1.8 | 1.8 | 1.8 | 2.6 | 2.6 |

Model | KTN130-10K | KTN130-18K | KTN170-10K | KTN200-10K | KTN200-18K | KTN280-10K | KTN280-18K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:10 | 1:18 | 1:10 | 1:10 | 1:18 | 1:10 | 1:10 |

Allowable input torque(Nm) | ≤55 | ≤55 | ≤72 | ≤90 | ≤90 | ≤135 | ≤135 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 60 | 60 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 1000 | 1000 | 1000 | 2000 | 2000 | 4000 | 4000 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 4 | 4 | 10 | 10 | 10 | 19 | 19 |

Adaptive motor | 57 stepper motor | 57 stepper motor | 86stepper motor | 86stepper motor | 86stepper motor | 130frame servo motor | 130frame servo motor |

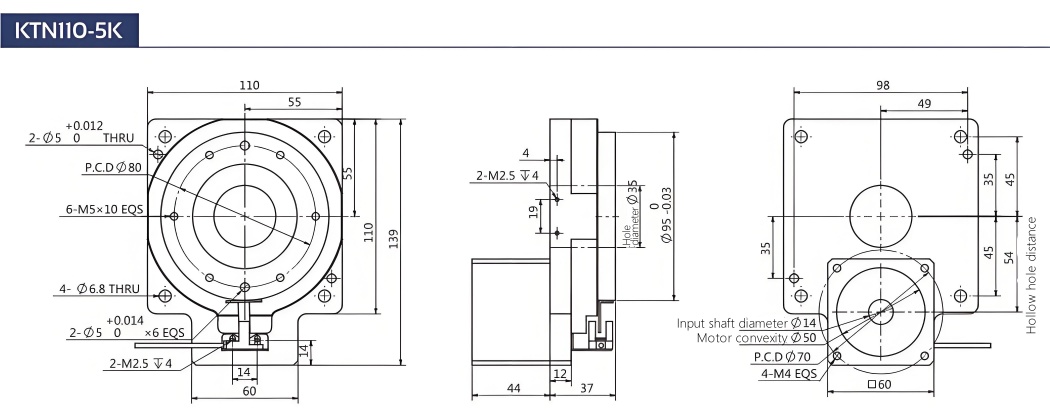

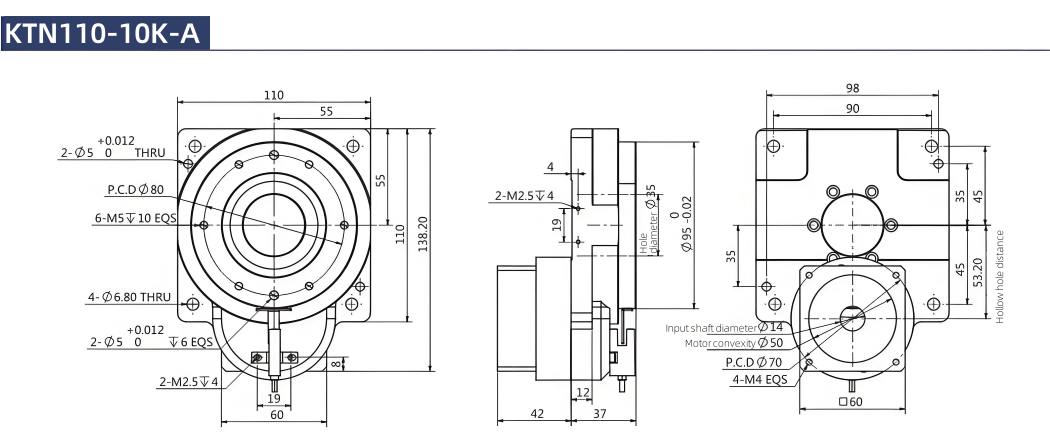

Dimensional drawing

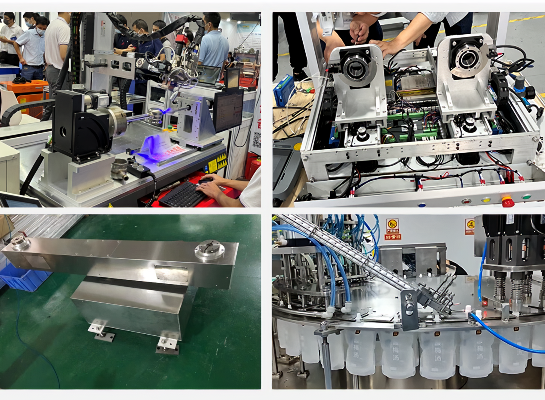

Application Case

KTN110 is widely used in precision automation scenarios including assembly lines, vision inspection systems, laser processing equipment, electronic manufacturing, medical devices, and indexing systems. Its high repeatability and hollow design make it ideal for systems that require center pass-through and high integration. Typical applications include rotating worktables, synchronized multi-axis motion setups, and compact robotic platforms in electronics or semiconductor industries.

Product Delivery

FAQ

Q1: Which motors are compatible with KTN110?

It supports popular brands such as Panasonic, Mitsubishi, Yaskawa, Delta, Xinje, and others. Custom motor flanges are available.

Q2: What is the maximum load it can handle?

The axial load capacity is 800N, and the maximum permissible torque is 47 N·m.

Q3: How long is its service life?

The precision service life is rated at 20,000 hours under standard working conditions.

Q4: What gear ratios are available?

5:1 for higher speed and 10:1 for higher torque and precision. Choose based on your application needs.

Q5: Can it be mounted in different orientations?

Yes, it supports horizontal, vertical, and inclined mounting configurations.

Q6: Is it suitable for harsh environments?

It has an IP40 rating, suitable for clean or light industrial environments but not recommended for wet or dusty areas.

Q7: Are 3D CAD files and motor adapter drawings provided?

Yes, 3D STEP files and interface drawings are available upon request.

Q8: How noisy is the platform during operation?

The unit operates with low noise, making it suitable for noise-sensitive environments.

Q9: Can cables and hoses be routed through the center?

Yes, the hollow shaft supports center pass-through for simplified system wiring.

Q10: What’s the lead time? Can it be customized?

Standard models ship in 3–7 days. Customizations such as flange, bore size, or motor interface are available.

Contact Us