Product Description

This series of incremental encoders features a built-in ASIC device, combining high reliability, long life, and strong anti-interference characteristics. The stainless steel spindle ensures operational stability and protection, the metal casing is impact-resistant, and the metal interface at the output end is waterproof, making it suitable for complex industrial environments.

Product parameters

GHB38 | GHB58 | |

Maximum speed (rpm) | 6000 | |

Starting torque | <0.05Nm | |

Maximum shaft load | Radial force 50N,Axial force 20N | |

Shock resistance | 50G/11ms | |

Vibration resistance | 10G 10~2000HZ | |

Moment of inertia | 4×10⁻8kg·m² | |

Operating temperature | -30~85℃ | |

Storage temperature | -35~95℃ | |

IP rating | IP51 | |

Weight | 100g | 300g |

Wiring table

Signal | A | B | Z | A- | B- | Z- | Vcc | GND |

Color | Green | White | Yellow | Brown | Gray | Orange | Red | Black |

No inverted signal | Green | White | Yellow | - | - | - | Red | Black |

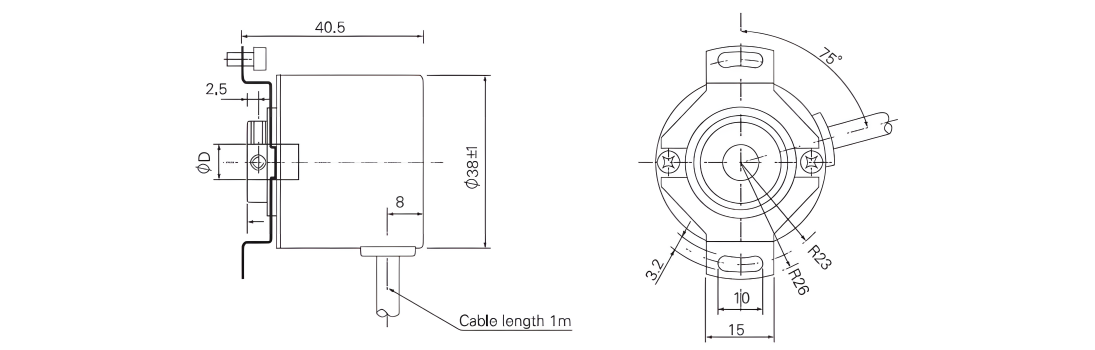

GHB38

Selection Guide

GHB38 | 08 | G | - | 1024 | B | M | - | L | 5 | · | C03 | |||||

↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ||||||||

Shell size | Output shaft | Cable Outlet | Resolution P/R | Output phase | Zero signal | Output Type | Working voltage | Special Code | ||||||||

Ø38mm | 05=Ø05mm | C = Side Outlet | 100~3600 | A=A | S=No Z signal | T = Voltage Output | 5=+5V | |||||||||

06=Ø06mm | G = Cable Outlet | B=A,B | M=Z signal output "1" | C = NPN | 526=5~26V | |||||||||||

08=Ø08mm | H = Rear Outlet | N=Z signal output "0" | CP = PNP | |||||||||||||

E = Cable Outlet | P = PNP+NPN | |||||||||||||||

J = Computer Socket Side Outlet (Pin) | L = Line Driver | |||||||||||||||

T = Computer Socket Rear Outlet (Pin) |

Output circuit | Open collector output | Voltage output | Complementary output | Long-line drive output |

Power supply voltage Vcc | 5~26 | 5±0.25, 5~26 | ||

Current consumption | ≤80mA | ≤150mA | ||

Load current | 40mA | 60mA | ||

Output H high level | Minimum Vcc*70% | Minimum Vcc - 2.5V | Minimum Vcc - 1.5V | Minimum 3.4V |

Output low high level | Maximum 0.4V | Maximum 0.8V | Maximum 0.4V | |

Rise time Tr | MAX 1us | MAX 200ns | ||

Fall time Tf | MAX 1us | MAX 200ns | ||

Maximum frequency response | 300kHz | |||

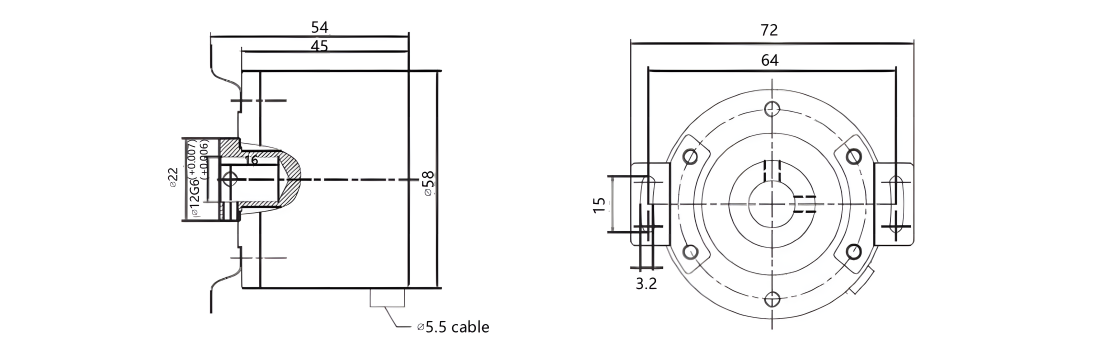

GHB58

Selection Guide

GHB58 | 08 | G | - | 1024 | B | M | - | L | 5 | · | C03 | |||||

↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ||||||||

Shell size | Output shaft | Cable Outlet | Resolution P/R | Output phase | Zero signal | Output Type | Working voltage | Special Code | ||||||||

Ø58mm | 08=Ø08mm | C = Side Outlet | 100~3600 | A=A | S=No Z signal | T = Voltage Output | 5=+5V | |||||||||

10=Ø10mm | G = Cable Outlet | B=A,B | M=Z signal output "1" | C = NPN | 526=5~26V | |||||||||||

12=Ø12mm | H = Rear Outlet | N=Z signal output "0" | CP = PNP | |||||||||||||

E = Cable Outlet | P = PNP+NPN | |||||||||||||||

J = Computer Socket Side Outlet (Pin) | L = Line Driver | |||||||||||||||

T = Computer Socket Rear Outlet (Pin) |

Output circuit | Open collector output | Voltage output | Complementary output | Long-line drive output |

Power supply voltage Vcc | 5~26 | 5±0.25, 5~26 | ||

Current consumption | ≤80mA | ≤150mA | ||

Load current | 40mA | 60mA | ||

Output H high level | Minimum Vcc*70% | Minimum Vcc - 2.5V | Minimum Vcc - 1.5V | Minimum 3.4V |

Output low high level | Maximum 0.4V | Maximum 0.8V | Maximum 0.4V | |

Rise time Tr | MAX 1us | MAX 200ns | ||

Fall time Tf | MAX 1us | MAX 200ns | ||

Maximum frequency response | 300kHz | |||

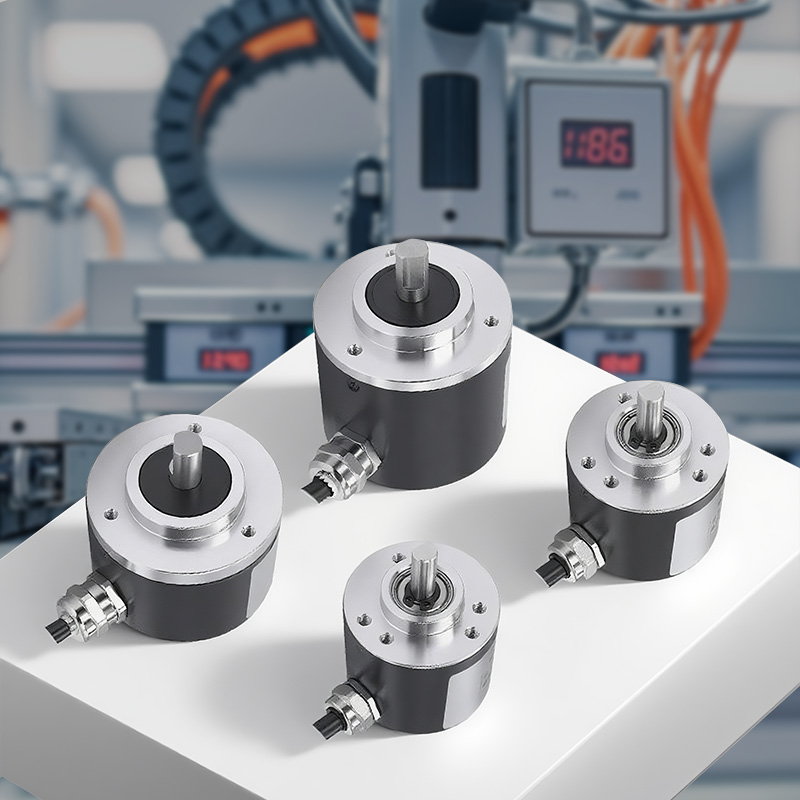

Product Display

Compatible Specifications: Available in 38/58mm diameters to accommodate various installation requirements.

Core Performance: Built-in ASIC for high reliability and strong

anti-interference capabilities.

Protection Advantages: Stainless steel spindle and metal housing for durability under harsh conditions.

Output Compatibility: Multiple output circuits, compatible with automation systems.

Flexible Customization: Aperture and protection level customization available.

Application Coverage: Covers automation, CNC, and other

high-precision applications.

Quality Control

The quality of encoders is directly related to the stability and reliability of industrial automation systems. We have built a full-process quality control system, strictly screening suppliers from raw material procurement to ensure that the performance of core components meets standards; in the production process, we use high-precision equipment and standardized processes, and cooperate with online detection technology for real-time monitoring; in the finished product stage, we conduct rigorous tests such as high and low temperature, electromagnetic compatibility, and life aging to eliminate performance risks. Each encoder has passed multiple quality inspection levels, and its excellent quality has laid a solid foundation for intelligent manufacturing, providing customers with long-term and stable use guarantees.

Application Cases

It covers scenarios such as automatic control, precision measurement, robotic motion, X-Y axis positioning, as well as printing and packaging production lines, computer equipment signal feedback, and CNC machining centers. It can operate stably in dusty, humid, and vibrating conditions, meeting high-precision and high-reliability requirements.