Product Description

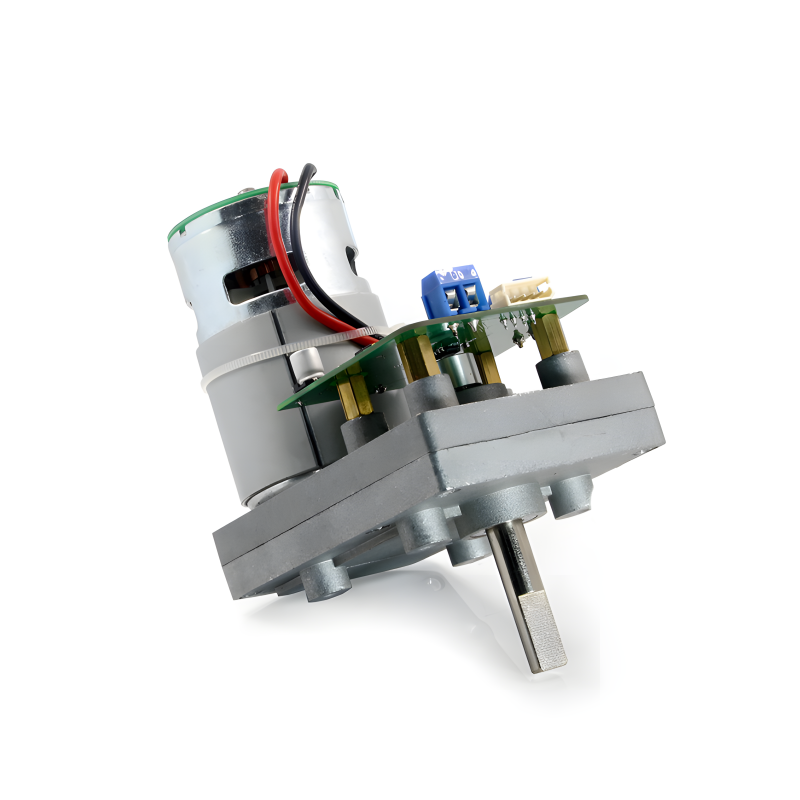

The SM1000/SM1500 are intelligent servos that integrate a reduction gear, brushless motor, magnetic encoder sensor, control board, and RS485 bus communication. They feature high precision, multi-turn rotation, multiple feedback and protection mechanisms, and support various control modes. Suitable for a variety of applications, including robotics, smart devices, healthcare, and logistics, they offer flexible installation, efficient debugging, and stable performance

|

|

Product parameters

Product Name | 12V 100kg.cm RS485/Magnetic Coded Serial Control BUS Servo | 12V 180kg.cm RS485/Magnetic Coded Serial Control BUS Servo | |

Model | SM-1000-C001 | SM-1500-C001 | |

Apply Environmental Condition | Storage Temperature Range | -30℃~80℃ | |

Operating Temperature Range | -15℃~70℃ | ||

Standard Test Environment | Temperature range | 25℃ ±5℃ | |

Humidity range | 65%±10% | ||

Mechanical Specification | Size | 95.5×65×85(mm) | |

Weight | 860g ±0.2 | ||

Gear type | Metal Gear | ||

Limit angle | 360degree (4096) | ||

Position range | -360°*7~360°*7 | ||

Bearing | 2 Ball bearings | ||

Horn gear spline | D shape dia=8.0mm | ||

Horn type | No | ||

Case | metal | ||

Connector wire | 150mm ±5 mm | ||

Motor | carbon motor | ||

Splash water resistance | NO | ||

Electrical Specification | Operating Voltage Range | 9~16V | |

Idle current (at stopped) | 15mA@12V | ||

No load speed | 0.25sec/ 60degree 40RPM| | 0.67sec/ 60degree 15RPM | |

200mA@12V | |||

Stall current | 4500mA@12V | ||

Peak stall torque | 120kg.cm(12N.m)@12V | 180kg.cm(18N.m)@12V | |

1669.4oz.in | 2504.1oz.in | ||

Rated torque | 40kg.cm(4N.m)@12V | 60kg.cm(6N.m)@12V | |

Stall current | 4500mA@12V | ||

Note: * is the average value when the servo is running with no load. | |||

Control Specification | Sensor | 12-bit high-resolution magnetic encoder | |

Control mode | Position servo / Speed control / PWM control | ||

Command signal | Bus Packet Communication RS485 | ||

Control frequency | 333Hz | ||

Protocol type | Half duplex Asynchronous Serial Communication | ||

ID range | 0-253 | ||

Communication baud rate | 38400bps ~ 1 Mbps | ||

Rotation angle | 360°(when4096) | ||

Feedback Feedback | Load,Speed,Input Voltage,Current | ||

Position Sensor Resolution | Magnetic Coded(360°/4096) | ||

(1) Under static working current, the SM1000/1500 servo is powered but does not move.

(2) Under no-load current working condition, the SM1000/1500 servo moves under no load.

(3) Under stall current working condition, the current of the SM1000/1500 servo when it outputs maximum torque.

(4) The baud rate can be modified to 500K, 250K, 128000, 115200, 76800, 57600, 38400.

(5) The maximum number of bus nodes that can be used depends on the power supply capacity and the allowable current specification of the cable. It is recommended to set one power supply for 8 groups of servos.

(6) The stall torque is the maximum stall torque of the servo. The actual working torque is 1/3-1/5 of this value as the suitable working point.

Mechanical dimensions (SM1000 and SM1500 have the same appearance and structure)

Product Display

Any-angle installation:

No intermediate position calibration is required, supporting software or manual calibration, simplifying installation and maintenance.

Multi-turn high-precision rotation:

Supports up to ±7 turns (0.088° resolution), expandable to over ±100 turns.

Real-time feedback on all parameters:

Monitors temperature, load, speed, current, voltage, and position, with overheat, overload, overvoltage, and overcurrent protection.

Open PID debugging:

Supports customizable parameters such as motor stiffness, error compensation, and overshoot for more precise motion control.

Magnetic encoder + bus control:

12-bit contactless absolute encoder, RS485 daisy-chain networking, up to 254 IDs.

Multiple control modes:

Position servo, speed control, PWM constant force output, supporting standalone or group control.

Quality Control

This product undergoes rigorous quality control before leaving the factory. From the meticulous selection of core components to the high-precision manufacturing and assembly of the motor and gear train, every detail is ensured to be tight and reliable. Comprehensive performance testing precisely verifies torque, angular accuracy, and response speed, and verifies stability in harsh environments such as high and low temperatures, humidity, and vibration. All products undergo long-term endurance cycling and numerous electrical tests, including voltage, current, and electromagnetic compatibility tests, ensuring that each servo delivers superior performance and durability, providing you with a reliable and secure motion control experience.

Application Cases

Robotics:

Driving bionic arms and robot joints

Smart home:

Pan/tilt tracking and silent opening and closing

Industrial automation:

High-precision grasping and sorting positioning

Smart logistics:

Shuttle positioning and high-speed sorting

Precision medicine:

Micromanipulators and surgical robots

Educational innovation: Teaching robots and

scientific research prototypes