Product Description

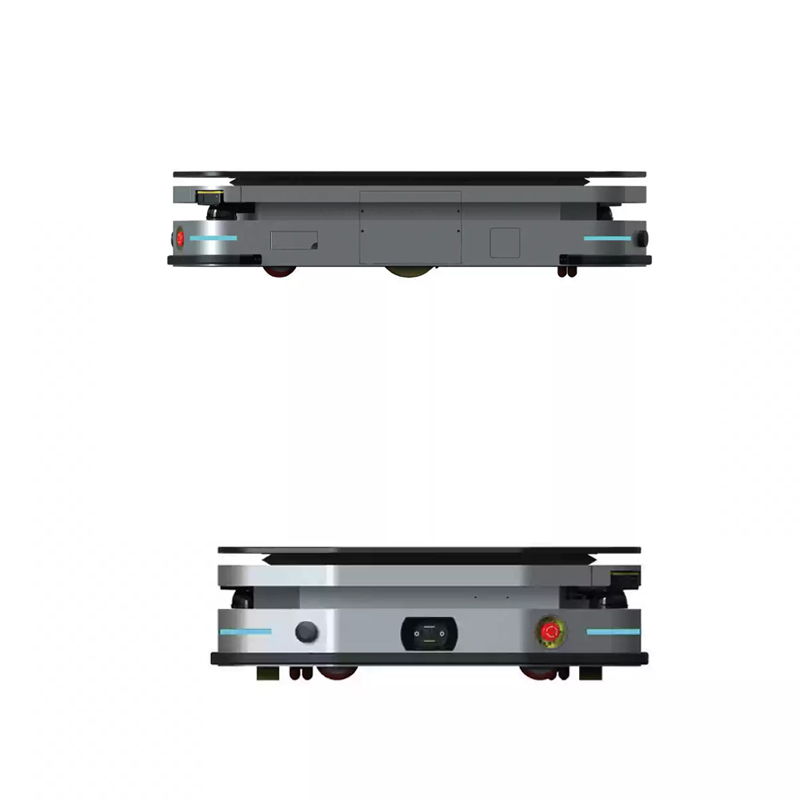

Lifting transport robot WWAGV-JS

The jack-up transport robot is an automated and intelligent device designed specifically for the warehousing and logistics industries. It integrates advanced navigation technology, machine vision and intelligent algorithms, and can autonomously complete tasks such as cargo identification, handling, positioning and stacking, significantly improving the efficiency and accuracy of warehousing and logistics operations.

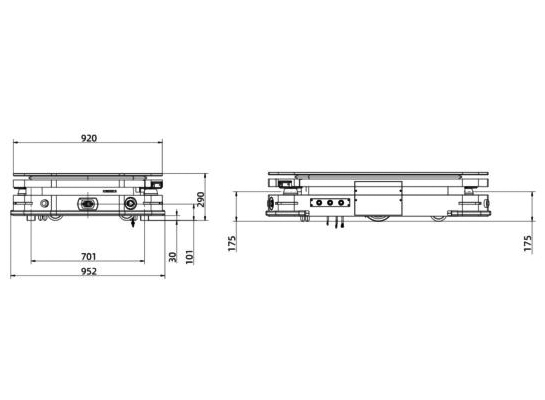

Product parameters

| Basic parameters | Product Name | Laser SLAM safe lifting and transporting robot |

| Navigation | Laser SLAM | |

| Machine size | 1330 x952 x 290 mm | |

| Rotation diameter | 1460 mm | |

| Weight (including battery) | 265 kg | |

| Maximum load | 500/1000 kg | |

| Chassis ground clearance | 30 mm | |

| Lifting platform size | 1300 x 920 mm | |

| Maximum lifting stroke | 60±1 mm | |

| Navigation laser scanning altitude (reference) | 175 mm | |

| Ambient temperature and humidity range | Temperature: 0℃~50℃/Humidity: 10%~90%, no compression condensation |

| Performance parameters | Passability (slope/step/gap) | ≤5%/5 mm/10 mm |

| Minimum passage width | 1050 mm | |

| Navigation position accuracy | ±5 mm | |

| Navigation angle accuracy | ±1° | |

| Travel speed | ≤1.5 m/s |

| Battery parameters | Battery Specifications | 48V/40 Ah(Lithium Iron Phosphate) |

| Comprehensive battery life | 7h | |

| Charging time (10%~80%) | ≤2 h | |

| Charging mode | Manual/Automatic |

Technological Innovation

CE certification: Passed CE safety certification (ISO 3691-4:2020) and other related certifications.

Super cost-effective: 10,000-level super cost-effective general-purpose vehicle chassis, accurate cost reduction and efficiency improvement.

More intelligent algorithm: shelf identification and correction, QR code secondary positioning, hybrid navigation, automatic following, fifth-order Bessel path.

Full load and strong endurance: The charging pile can choose 40 A fast charging, charging for 1 hour, and full load endurance of 7-8 hours.

Wide-area rack identification: Supports wide-area all-round identification of racks at a distance of ≥7cm on one side, automatic correction, and improves the success rate of loading.

Complete system software: A full set of system software can easily realize AMR deployment, scheduling, operation, information management, etc. throughout the factory.

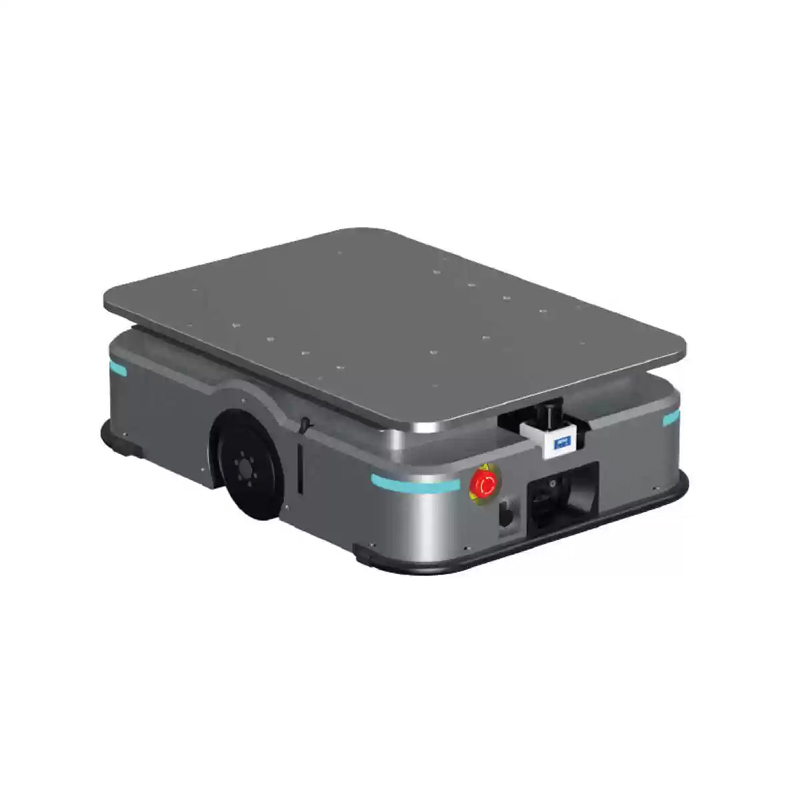

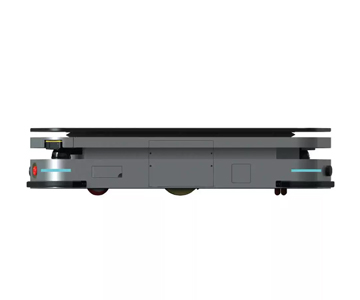

Product Display

Highly automated

Robots can work 24 hours a day without interruption, reducing human intervention and improving the continuity and stability of warehousing and logistics operations.

Intelligent navigation and positioning

Using laser SLAM navigation technology, precise positioning is achieved to ensure that the goods arrive at the destination accurately.

Powerful lifting capability

Equipped with a lifting mechanism, it can easily carry and stack heavy objects to meet the operating requirements of shelves of different heights.

Flexible adaptation to multiple scenarios

Compact in size and highly flexible, it can adapt to various complex storage environments and production line layouts.

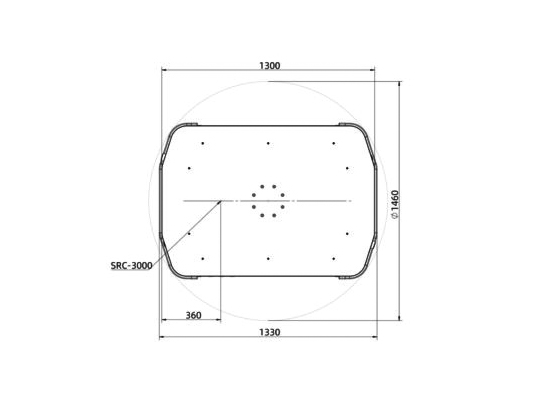

Size & Interface

Application Cases

Company Information

About Oneway

Changsha Oneway Robotics Co., Ltd. was founded by former members of the National University of Defense Technology’s robotics team. The company focuses on security patrol robots and inspection robots and system solutions, aiming to enhance operational efficiency in security tasks through the use of security robots and control systems. The company possesses advanced technology in robot chassis control, low-speed unmanned driving, and image processing algorithms. It has vertically applied these technologies in areas such as park security, port patrols, specialized industry inspections, industrial distribution, and military applications. Meanwhile, Oneway robotics, under its main robot business, has incubated two internal sectors—Oneway Intelligent Control and Oneway IoT (Internet of Things), forming a business line with Oneway Robotics at its core and Oneway Intelligent Control and Oneway IoT as complementary components. This structure allows us to consistently create competitive value and services for our clients.

Cooperative partner