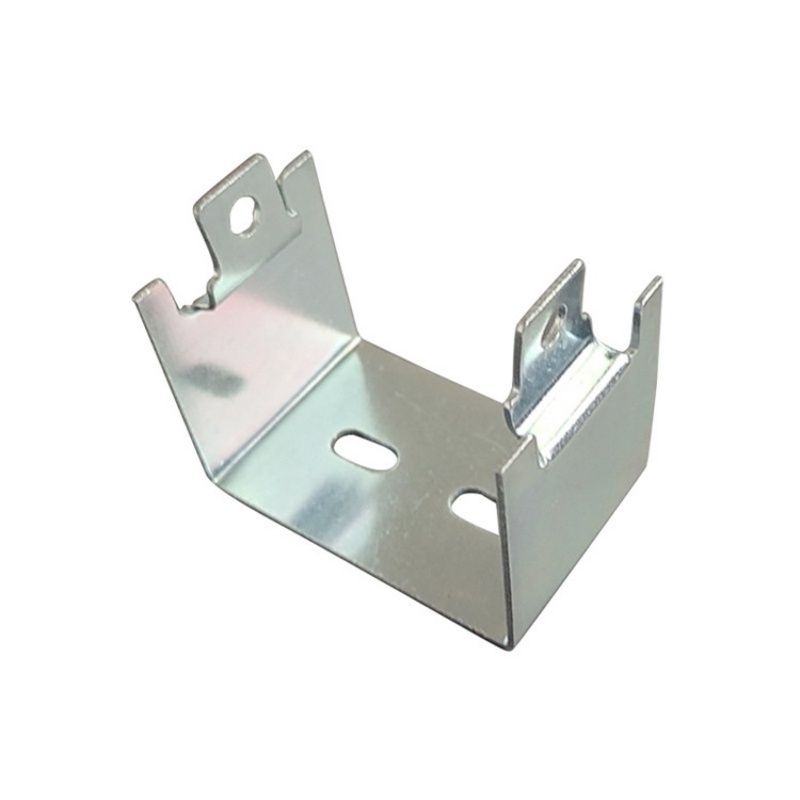

Product Description

We have extensive experience in stamping and can meet your needs based on your drawings.

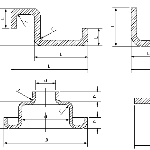

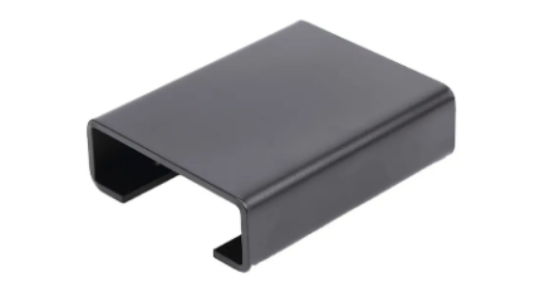

Stamping involves placing a flat sheet of metal into a press where tool and die surfaces form the metal into a net shape. Stamping includes a variety of sheet metal forming manufacturing processes such as punching, blanking, embossing, bending, flanging and coining using a mechanical press or punch. This may be a single-stage operation, where each stroke of the press produces the desired shape on the sheet metal part, or it may be done in a series of stages.

Product parameters

| Mold Life Time | 300K times |

| Product Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide |

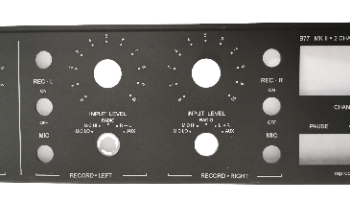

| Size | 1) According to customers' drawings 2) According to customers' samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Material

brass

aluminum

steel

stainless steel

Processing capability

We have extensive processing capabilities, including the ability to produce high-precision parts through metal forming techniques such as progressive stamping, deep drawing and blanking. We have advanced machinery, including CNC punching machines, hydraulic presses and servo-driven equipment, which enables it to process a variety of materials such as steel, aluminum, copper and other alloys. The process is highly flexible and can produce complex shapes and intricate designs with tight tolerances.

We specialize in precision customized stamping, offering tailored solutions that meet the unique requirements of each client. Using advanced technology and expert craftsmanship, we can produce highly accurate, intricate stamped parts that adhere to tight tolerances.

Whether it's for small, complex components or large-scale production runs, our stamping services are designed to deliver exceptional quality and performance, ensuring that every product meets the highest standards of precision and reliability.

Additional processes

In addition to precision customized stamping, we offer a range of complementary processes to enhance the functionality and quality of stamped parts. These additional processes include:

Deburring and Finishing: To ensure smooth edges and surfaces, we provide deburring and finishing services, removing any sharp edges or imperfections from the stamped components.

Forming and Bending: For parts that require shaping or altering their dimensions, we offer precise forming and bending capabilities to meet specific design requirements.

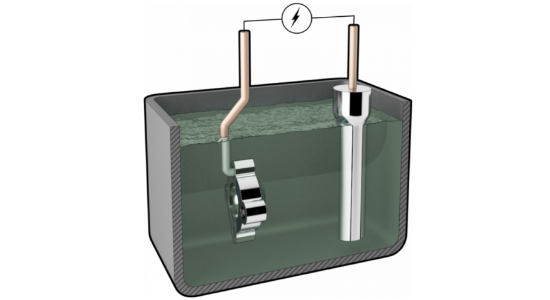

Coating and Plating: We can apply protective coatings or plating, such as powder coating, zinc plating, or anodizing, to improve corrosion resistance, enhance appearance, or provide additional surface properties.

These additional processes allow us to deliver fully customized, high-quality stamped products tailored to meet the exact needs of our customers across a variety of industries.