Product Description

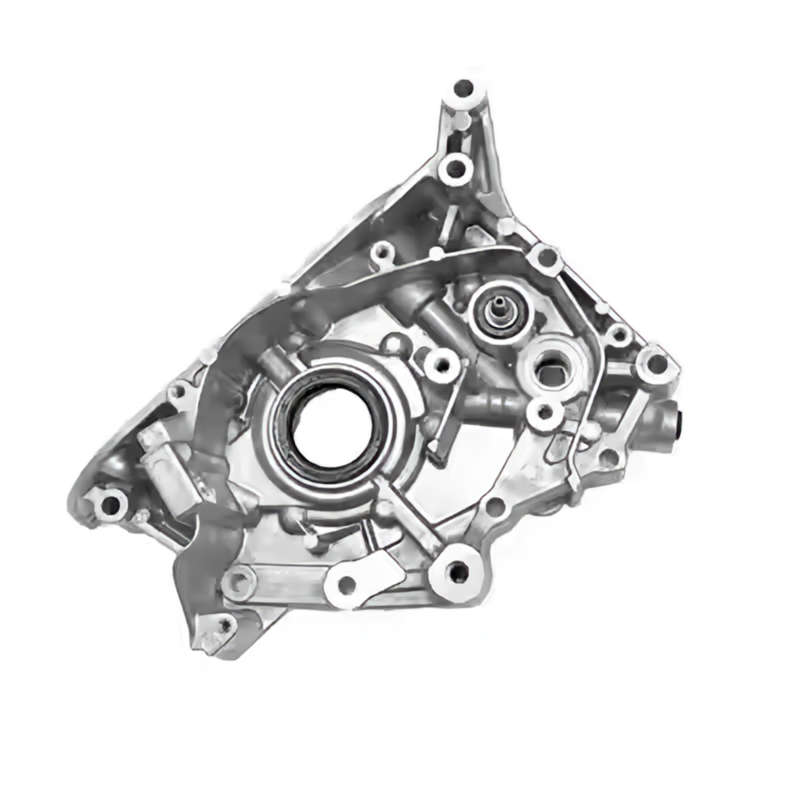

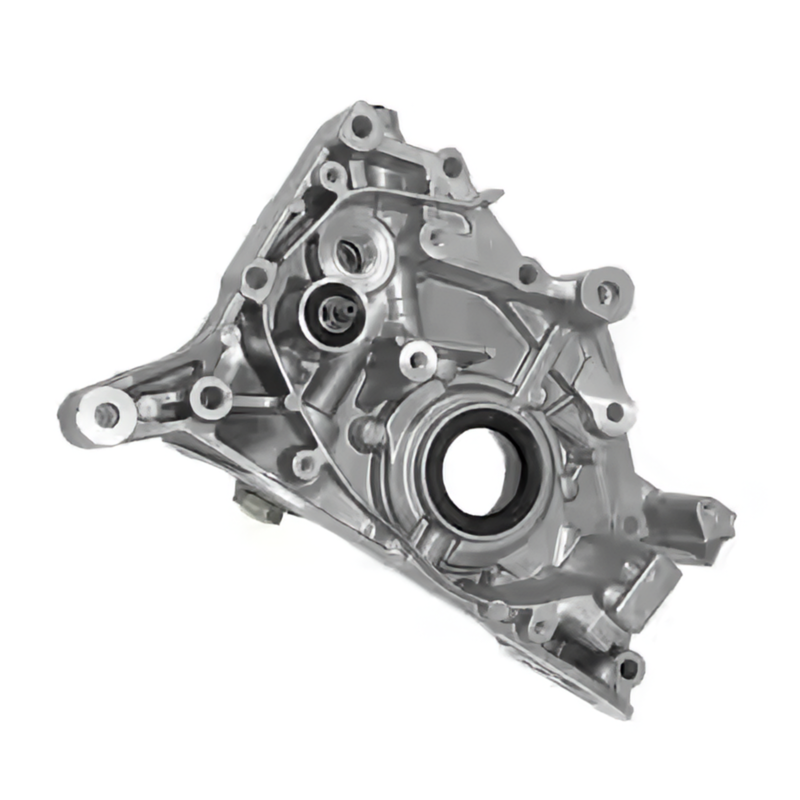

Aluminum car housing parts are lightweight, durable, and corrosion-resistant. Designed for optimal heat management and performance, they help reduce vehicle weight, improve fuel efficiency, and ensure long-lasting reliability in engine housings, transmission cases, and other key automotive components

Product parameters

| Service | Investment Casting | Die Casting | Sand Casting | Stamping/Forging |

|---|---|---|---|---|

| Weight | 5g-50kg | 0.5kg-1000kg | 0.5kg-1ton | - |

| Capacity | 200ton/month | 500ton/month | 1000ton/month | 200ton/month |

| Surface roughness | 6.4 Raum/254 Rauinches | 3.2 Raum/125 Rauinches | 12.5 Raum | - |

| MOQ | 200 pcs | 1000 pcs | 200 pcs | 1000 pcs |

| Material for cast | 304 316 stainless steel carbon steel | aluminum | aluminum | brass |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Transmission Cases

Aluminum housing is commonly used in automatic and manual transmission systems for its lightweight and durability

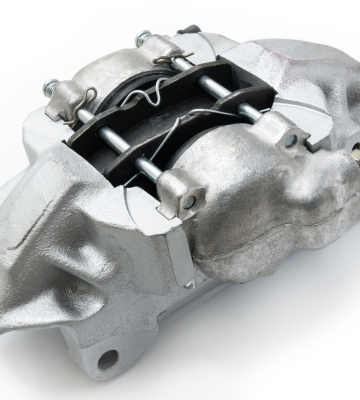

Brake Calipers

Aluminum brake calipers are used in high-performance vehicles to reduce weight while maintaining strength and durability

Air Intake Manifolds

These are often made from aluminum to reduce weight and improve the airflow efficiency of the engine

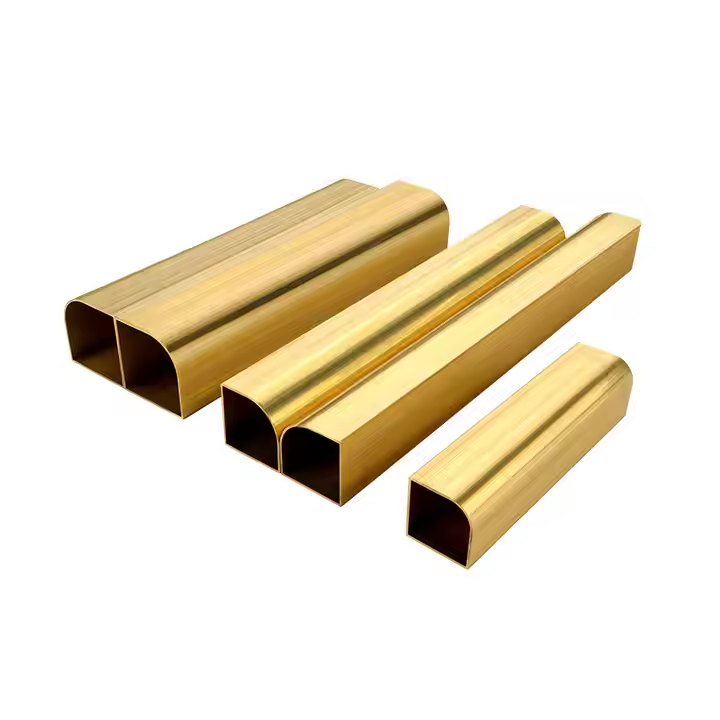

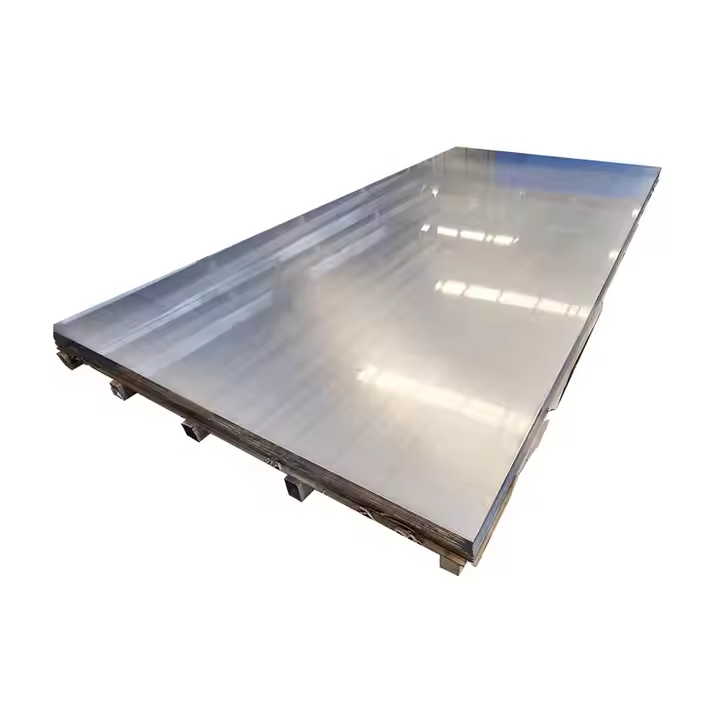

Material

brass

Aluminum

Quality Control

Controlling the temperature of the molten metal and mold is key to avoiding defects like cracking or warping. Ensuring mold accuracy before casting prevents size errors. Managing pouring speed and pressure prevents air bubbles that could weaken the part. Measuring the size and shape of the cast ensures they meet standards. Checking metal purity avoids contamination. Monitoring cooling and post-casting stages ensures consistent quality, as small changes can impact the final product

Processing capability

Processing capability reflects a manufacturing process’s ability to consistently meet quality standards. Key elements include:

Production Capacity: Maximum output within a set timeframe.

Accuracy and Tolerance: Maintaining precise dimensions.

Material Suitability: Compatibility with various materials.

Adaptability: Adjusting to different designs and sizes.

Quality Assurance: Measures to monitor and ensure quality.

Additional processes

Manufacturing involves additional processes such as precision machining, heat treatment for strengthening materials, surface finishing to improve aesthetics and resilience, welding and assembly, as well as quality inspection, protective coating, and packaging to ensure safe transport. These steps enhance product quality and streamline production, aligning with customer expectations effectively