Product Description

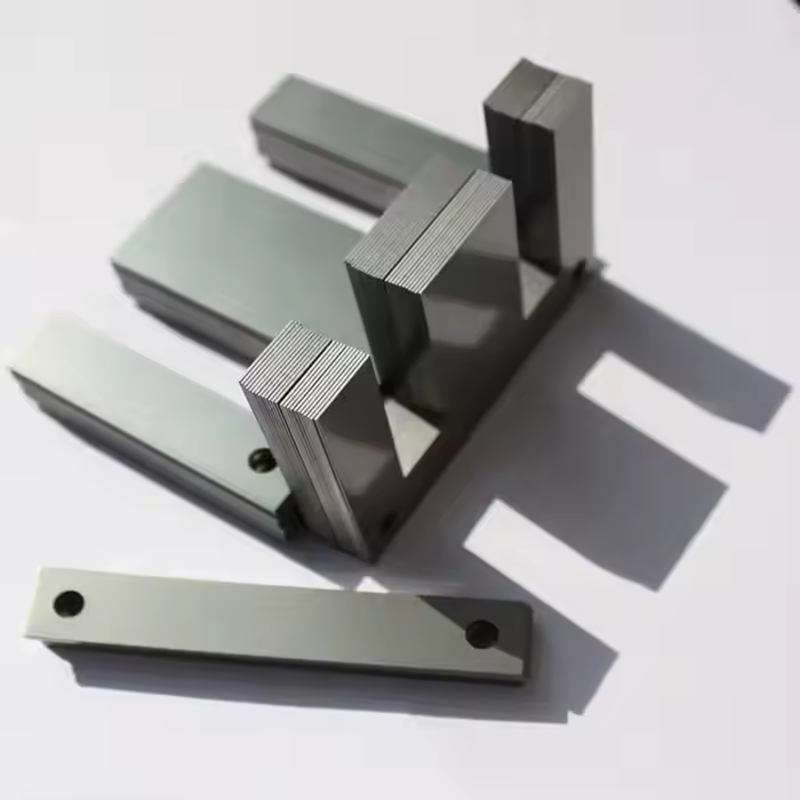

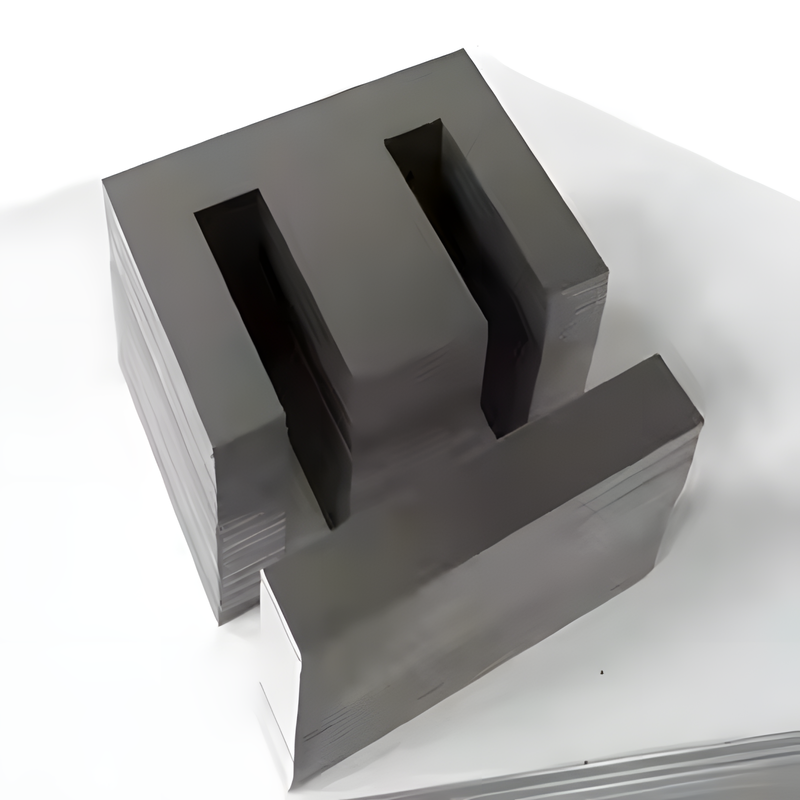

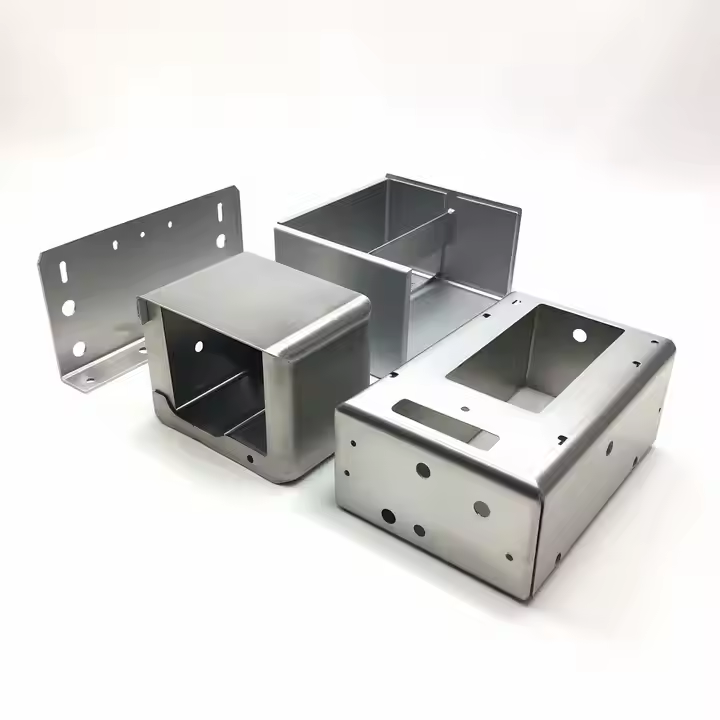

We provide custom sheet metal fabrication services, specializing in aluminum and stainless-steel materials. Our offerings include precision laser cutting, bending, welding, and powder coating, designed to meet the specific needs of your projects. Whether it's creating custom enclosures, protective cases, or other intricate components, we ensure high-quality, durable, and accurate results. With our advanced equipment and expert craftsmanship, we deliver tailored solutions that are both cost-effective and built to last.

Product parameters

| List | Details |

|---|---|

| Product name | Sheet Metal Fabrication Stamping Bending Welding Turnning Parts |

| Materials Avaliable | Stainless Steel Aluminum Metals Copper |

| Tolerance | 0.01-0.05mm |

| MOQ | Small Orders Accepted |

| Surface treatment | Painting\Powder Coat\Polish\Anodize |

| Process | Laser Cutting Bending Stamping |

| Drawing format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Single package size | 30X20X20 cm |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

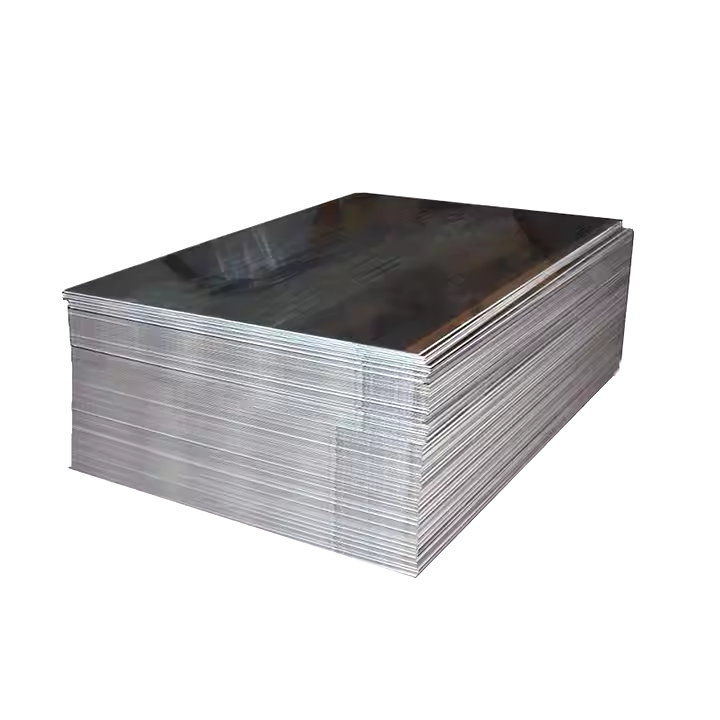

Material

Stainless steel

Aluminum alloy sheet

Galvanized sheet

Carbon steel

Quality Control

Our QC process ensures the highest standards of quality throughout each stage of fabrication. We conduct thorough inspections of all materials before production to verify compliance with specifications. Laser cutting, bending, and welding operations are monitored for precision, with real-time measurements taken to ensure tight tolerances. Post-production, all parts undergo final inspection for surface finish, dimensional accuracy, and functionality. Only parts that pass rigorous quality checks are approved for delivery, ensuring consistency and performance in every product.

Processing capability

Our processing capabilities include a wide range of services to meet diverse project needs. We specialize in precision laser cutting for intricate designs and tight tolerances, using advanced CNC machines to cut aluminum, stainless steel, and other metals with exceptional accuracy. Our bending capabilities allow for the formation of complex angles and shapes, ensuring a perfect fit for custom enclosures and cases. Welding is performed by skilled technicians using TIG and MIG techniques for strong, clean joints, and ensuring structural integrity. For added durability and aesthetic appeal, we offer powder coating to provide a smooth, protective finish on metal parts. We also handle punching and stamping for high-volume production, delivering uniform and precise cuts.

Additional processes

Our CNC machining services allow for further customizations and intricate detailing. We have the capacity to handle both prototype and large-scale production runs with quick turnaround times. Each project is backed by rigorous quality control to ensure all components meet industry standards and customer specifications. With our versatile machinery and expert team, we provide comprehensive solutions for a wide range of industries and applications.