Product Description

Cast iron stainless steel combines the strength and durability of cast iron with the corrosion resistance and sleek appearance of stainless steel. This material is ideal for heavy-duty applications, offering high resistance to wear and extreme temperatures while maintaining a long lifespan. Commonly used in industries such as automotive, construction, and manufacturing, it is perfect for components requiring both strength and protection from environmental elements.

Product parameters

| Material | steel, stainless steel, aluminum, copper, brass, alloy, etc. |

| Thickness | 0.1mm to 12mm, as your request |

| Sizes | 1) According to customers' drawings 2) According to customers' samples |

| Surface treatment | zinc, nickle, chrome plating, powder coating, painting, etc. |

| Packing | Polybag+Carton box+Wooden case/Pallet, according to customer's request |

| Shipment | 1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive 2) By air to air port, usually, 3-4 days to arrive 3) By Sea port, usually 15-30 days to arrive |

| Delivery Time | depend on the quantities, usually around 10 days. |

| Payment Term | T/T, L/C, Trade Assurance |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

Process Type

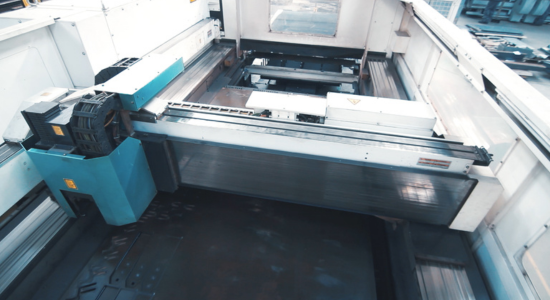

Machinery Parts

In heavy machinery, components such as gears, housings, and bearings are often made from cast iron stainless steel. The material’s toughness and resistance to wear and tear are crucial for ensuring that machinery operates smoothly and lasts for extended periods

Structural Supports

In construction, cast iron stainless steel is used for structural supports such as beams, columns, and brackets because of its high tensile strength and durability. This material provides reliable support for buildings and infrastructure, especially in environments subject to heavy loads and corrosive conditions

Home Appliances

Sheet metal is used in the production of home appliances such as storage cabinets, shelves, and various household items because it offers durability and aesthetic appeal. It can withstand long-term use, is easy to clean, and is ideal for items that undergo frequent handling or movement in the home

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control of cast iron stainless steel involves rigorous testing to ensure the material meets required standards for strength, durability, and corrosion resistance. This includes inspecting surface finishes, dimensional accuracy, and structural integrity through various methods like non-destructive testing and hardness testing. The process ensures that components are reliable and perform well under extreme conditions.

Processing capability

The processing capability of cast iron stainless steel includes casting, machining, and finishing techniques. It allows for the creation of complex shapes and precise components with high durability. Various processes like welding, heat treatment, and surface coating are also used to enhance its strength and resistance to corrosion, making it suitable for demanding industrial applications.

Additional processes

Additional processes for cast iron stainless steel include heat treatment to improve strength and hardness, surface coating to enhance corrosion resistance, and machining for precise dimensional control. These processes ensure the material's performance in harsh environments and extend its lifespan in applications like automotive, manufacturing, and heavy machinery.