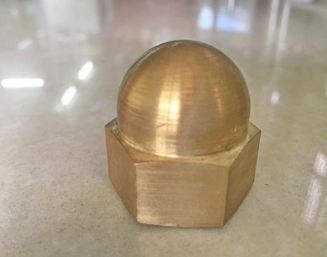

Product Description

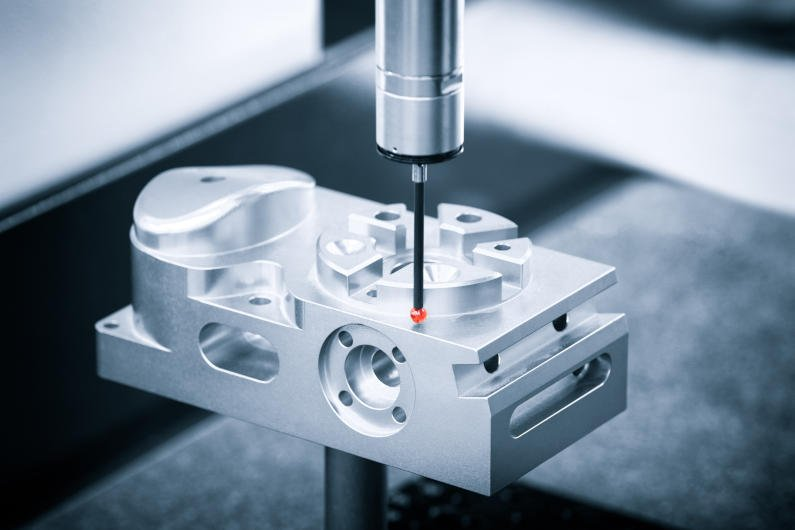

It is a workpiece produced using a computer-controlled lathe, which allows for precise and consistent cutting, grinding, and shaping of materials such as metal, plastic, or other materials. The resulting workpieces are typically cylindrical or rotationally symmetric in shape, such as drive shafts, axles, pistons, or machine components. CNC turning is suitable for producing parts that require high precision and complex shapes.

Product parameters

| List | Details |

|---|---|

| Product Name | CNC Turning Mold Parts |

| Material Capability | Steel Alloys, Stainless Steel, Precious Metals, Hardened Metals, Copper, Brass, Bronze, Aluminum |

| Type | Milling, Drilling, Etching/Chemical Machining, Laser Cutting, Milling, Turning Services, Wire EDM Cutting, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Material | Customer's Specifications |

| Application | Used in Molds |

| Quality Control | 100% Quality Inspection, Inspection Process Guarantee |

| Our Service | arantee Our Service |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Silver

Brass

Copper

Quality Control

Quality control for CNC-milled parts, such as those used in electrical equipment and other machinery, involves material quality inspection, dimensional accuracy checks, and surface inspections for defects. The parts must undergo performance testing for heat resistance and durability. Electrical connection checks and safety standard inspections are necessary to prevent hazards. Waterproof and dustproof testing is also important, and the packaging must be able to protect the parts during transportation.

Processing capability

Processing capability for CNC-milled parts refers to the factory's ability to handle various materials, sizes, and complexities with high precision. This includes producing complex designs, managing different production volumes, and post-production operations such as polishing or coating. The use of automation and efficiency helps maintain consistent quality while increasing production capacity, allowing the factory to meet specific production demands.

Additional processes

Additional processes in CNC machining include grinding, heat treatment, polishing, coating, welding, assembly, and laser engraving. These operations help improve surface quality, enhance material strength, add protective coatings, weld parts together, and assemble components to create a complete product. Polishing and coating enhance the appearance and durability of the parts, while heat treatment alters the material properties to improve performance. Laser engraving is used for identification or branding, while welding and assembly are critical processes for joining parts to form the final product. These processes ensure that the parts meet both functional and aesthetic requirements.