Product Description

We are a leading manufacturer specializing in providing high-quality, customized OEM casting parts. With advanced manufacturing processes and state-of-the-art technology, we cater to a wide range of industries, delivering precision-engineered components tailored to meet specific customer requirements. Our expertise in casting allows us to offer solutions that ensure durability, performance, and cost-effectiveness. Whether you need small or large production runs, we are committed to delivering products that align with your exact specifications, while maintaining the highest standards of quality and reliability.

Product parameters

| Service | CNC Turning, CNC Milling, Laser Cutting, Bending Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Die Casting |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel:SUS303, SUS304,SS316,SS316L,17-4PH,etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo,etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68,H70,Bronze, Copper | |

| Titanium: GradeF1-F5 | |

| Size or shape | According to customer drawings or requests |

| Tolerance | Highest = +/-0.005mm or +/- 0.0002 inch |

| Drawing accepted | Stp, step, igs, iges, x_t, sat, stl, sldxml, prt, ipt, dxf, dwg, PDF, jpg, jpeg, png, etc. |

| MOQ | 1PCS |

| Service mode | OEM or ODM |

| Certification | IATF 16949: 2016/ISO 9001:2015 |

| Surface Treatment | Anodizing, Bead blasting, Si6%creen, PVD Plating,Zinc/Nickel/Chrome/ Titanium Plating,Brushing, Painting,Powder Coating,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. |

| Delivery | DHL, FedEx, EMS, UPS, or customer's requirements |

| Package | Inner pearl button,wooden case,or customized. |

Custom Process

Upload your design

Design analysis

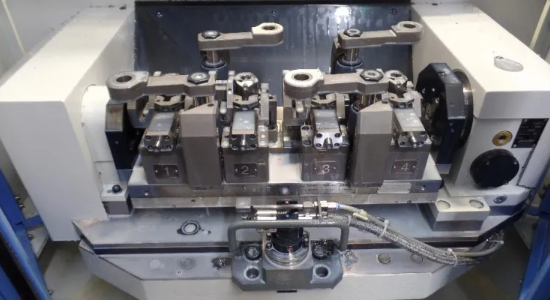

Start production

Receive your parts

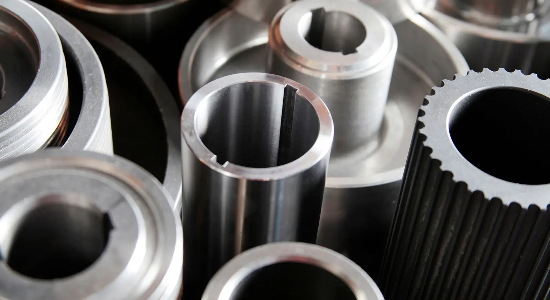

Process Type

Die casting

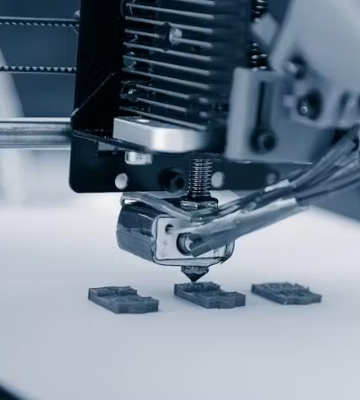

3D printing

Surface treatment

Material

Stainless steel

Aluminum

Titanium

Brass

Additional processes

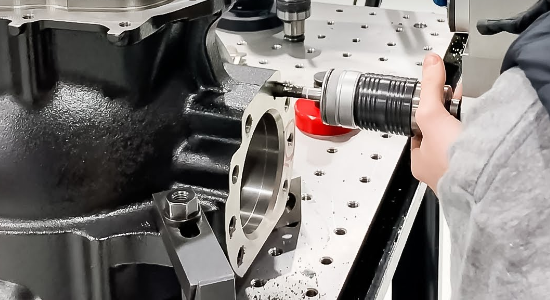

Machining: After casting, parts may require additional machining processes, such as CNC milling, turning, or grinding, to achieve precise dimensions and smooth surfaces.

Surface Finishing: Various techniques can be applied to improve the surface appearance and performance of casting parts, including:

- Polishing: Achieving a smooth, shiny finish.

- Anodizing: Enhancing corrosion resistance and appearance, often used for aluminum parts.

- Powder Coating: Applying a protective coating for better corrosion resistance and aesthetics.

- Painting: Providing a colored finish to improve both protection and visual appeal.

Tapping and Threading: Threads may be added to the parts for fastening purposes, either during the casting process or as a post-casting operation.

These additional processes ensure that casting parts meet the specific performance, aesthetic, and durability requirements for their intended applications.