Product Description

highly flexible manufacturing process that uses computer-controlled machines to create parts tailored to specific customer requirements. It allows for the production of complex shapes, tight tolerances, and precise details from various materials, including metals, plastics, and composites. The process involves programming the CNC machine with a custom design to automate cutting, drilling, milling, and other operations. Custom CNC machining is ideal for creating prototypes, small batches, or one-of-a-kind parts with high precision. It ensures repeatable quality and can accommodate unique specifications for various industries. This process is commonly used in aerospace, automotive, medical, and electronics applications.

Product parameters

| List | Details |

|---|---|

| Brand Name | AP CNC |

| Product name | Custom Metal Parts |

| Process | Investment Casting+machining |

| Material | Metal |

| surface treatment | Ra 0.8 |

| Weight range | 0.02 to 30kg |

| Quality Control | ISO9001:2015 |

| Finish | According to customer's request |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

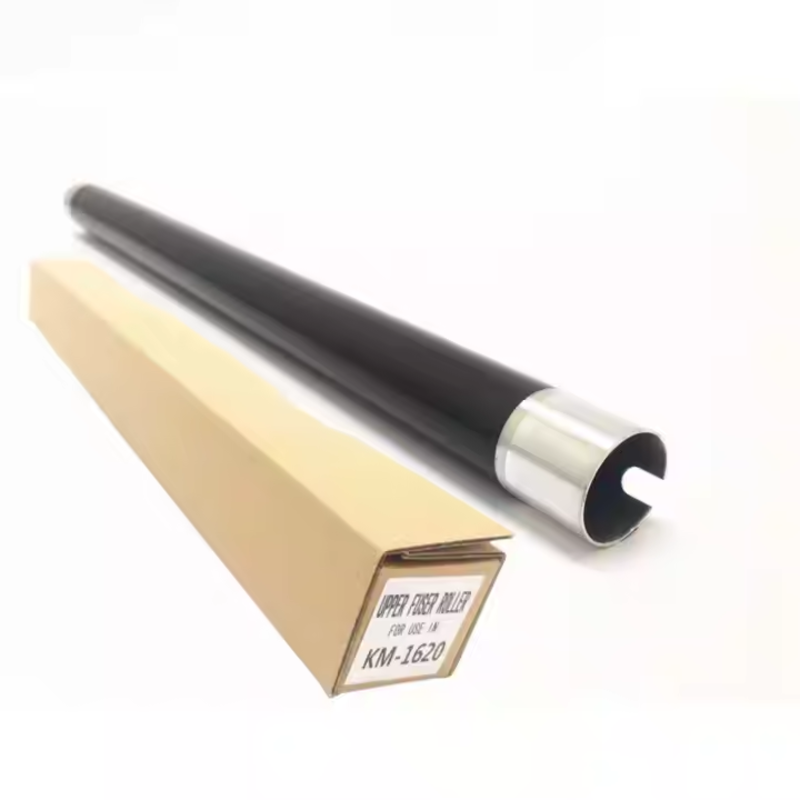

Process Type

Milling & Drilling

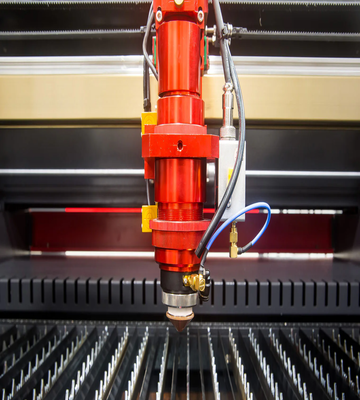

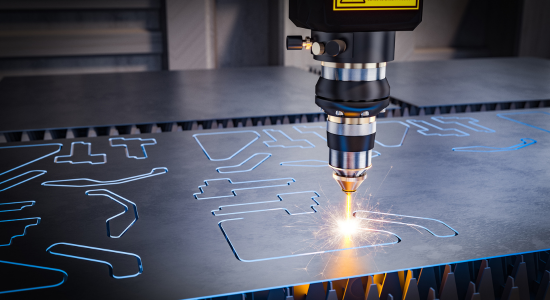

Laser Cutting

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Custom CNC machining ensures that each part meets precise specifications and high standards. During production, parts are regularly measured using tools such as calipers, micrometers, and CMM (Coordinate Measuring Machines) to check for dimensional accuracy. All machining processes are closely monitored to ensure tight tolerances and surface finish requirements are met. Post-machining inspections are conducted to identify any defects or imperfections. If any deviations are found, corrective actions are taken immediately. The final product undergoes thorough testing to verify functionality and performance before delivery.

Processing capability

The processing of custom CNC machining begins with the creation of a detailed CAD (Computer-Aided Design) model, which is then converted into a CNC-compatible program using CAM (Computer-Aided Manufacturing) software. This program defines the cutting paths, tool selections, and machining parameters based on the custom part design.

Once the program is ready, the workpiece, made of materials like metal, plastic, or composites, is securely mounted on the CNC machine using clamps or fixtures. The CNC machine then follows the programmed instructions to carry out a variety of operations such as milling, turning, drilling, and grinding. Multiple tools may be used for different tasks, with the machine automatically switching tools as needed during the process.

Additional processes

The machine carefully removes material layer by layer, maintaining high precision and tight tolerances throughout. Throughout machining, the process is monitored to ensure the machine operates within the required parameters. After machining, parts undergo thorough inspection for dimensional accuracy, surface finish, and functionality.

If necessary, secondary processes like deburring, polishing, or heat treating are performed. Finally, the completed custom parts are tested and verified for quality before being delivered to the customer.