Product Description

CYW501A series liquid level transmitter products use ceramic capacitive pressure sensing core as a signal measurement element, and through computer automatic test, for a wide temperature range of zero and sensitivity temperature compensation. The amplifier circuit is located in the housing, which converts the sensor signal to the standard output signal, giving full play to the technical advantages of the sensor.

Product parameters

| Basic parameter | |

|---|---|

| Measuring medium | Water (H2O), liquid or fluid (compatible with contact material) |

| Liquid level range | 0 ~ 1 ~ 40mH2O (see range selection table for details) |

| Medium temperature | -40 ~ 60℃ |

| Turn-on time | 20ms |

| Stability performance | ±0.1% FS/ year |

| Level overload | 200% full scale |

| Temperature drift | ±0.01%FS/℃ (within the temperature compensation range) ±0.05%FS/℃ (outside the temperature compensation range) |

| Temperature compensation | -20 ~ 80℃ |

| Explosion-proof type | Intrinsically safe Ex ia ⅡC T6Ga (4 ~ 20mA output only) |

| Class of protection | IP68 |

| accuracy level | 0.1%FS, 0.25%FS |

| Response frequency | Analog signal output ≤30Hz Digital signal output ≤5Hz |

| Resolution | Analog output 0.01%FS, digital output 0.05%FS |

| Overall weight | Probe ≈220g cable ≈60g per meter |

| Output power supply | |

| Output signal | 4~20mA、RS485 |

| Power supply range | 9~36VDC、12~36VDC、3~5VDC |

| Maximum power | |

| exportation | 4~20mA、RS485 |

| power | ≤0.02Us(W)、≤0.015Us(W) |

| Load characteristic | |

| Current mode | Load ≤{(Us-7.5) ÷0.02}Ω |

| Environmental condition | |

| Ambient temperature | -40 ~ 85℃ |

| Ambient humidity | 0% ~ 95%RH (no condensation, no condensation) |

| Overall material | |

| diaphragm | al2o3 ceramics (contact with tested medium) |

| shell | 316L stainless steel (contact with measured medium) |

| Sealing element | Nitrile rubber, fluorine rubber (contact with the measured medium) |

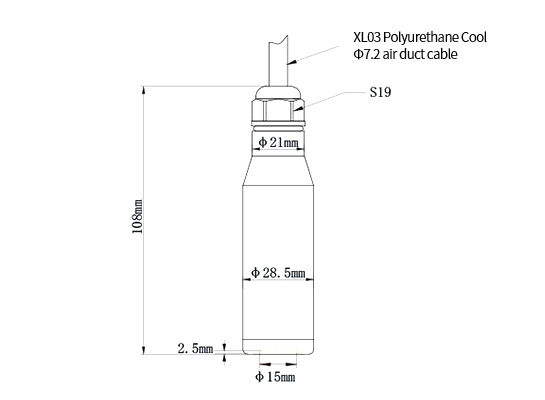

| cable | XL03 Polyurethane φ7.2 Gas cable (contact with the measured medium) |

| Mechanical stability | |

| Vibration resistance | 10g(20… 2000Hz) comply with IEC60068-2-6 standard |

| Impact resistance | 500g/ms complies with IEC60068-2-27 standard |

| Electrical protection | |

| Short circuit protection | permanent |

| Inverse pole protection | No damage, but no work |

| Insulation resistance | ≥100MΩ 500VDC |

| Insulation strength | 500VAC |

| Output restriction | |

| 4~20mA | Output range: 4mA to 20mA |

| RS485 | Output range: 0 to 2000 |

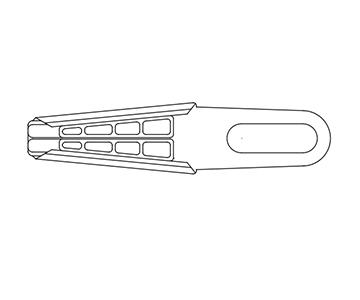

Product Display

The shell of CYW501A ceramic capacitive input liquid level transmitter is made of 316L stainless steel, the sensor core is made of ceramic capacitive measuring element, and the liquid part is made of ceramic material, so that it has the characteristics of anti-puncture contact, anti-corrosion, high precision, high stability, small blind area and so on. Can measure liquids, fluids or media with particles. Explosion-proof function is optional. Ceramic capacitive pressure sensing core integrated chip, wide voltage supply frequency cut-off design, strong anti-interference ability, lightning protection, current limiting, voltage limiting, reverse protection, anti-blocking, anti-corrosion, high precision, high stability, small blind area can measure liquid, fluid or particle media.

The formula of pressure on the liquid surface of the sensor is :P=pgh + Po formula:

P: Pressure strength of the sensor against the liquid surface (for convenience of understanding, hereinafter referred to as pressure)

p: Density of the measured liquid (1g/c㎡ by default)

g: Acceleration of gravity (9.8m/s by default during debugging)g:

Po: atmospheric pressure at the liquid surface

h: The depth of the sensor into the liquid

When the sensor is put into a certain depth of the measured liquid, the pressure of the measured medium is introduced into the positive pressure chamber of the sensor, and the atmospheric pressure Po on the liquid surface is connected to the negative pressure chamber of the sensor through the cable airway to offset the Po on the front of the sensor, so that the sensor can measure the pressure :pgh, obviously, by measuring the pressure P, the liquid level depth can be obtained.

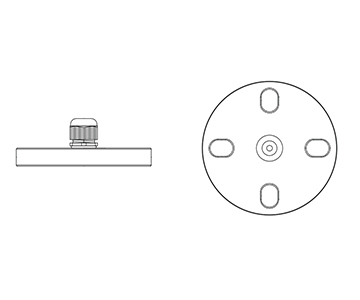

Size & Interface

Application Cases

Star Sensor Manufacturing Co., LTD., the main products involved in the pressure transmitter, liquid level transmitter, temperature transmitter temperature and humidity transmitter, differential pressure transmitter, soil moisture transmitter, 3051 transmitter and related instrumentation accessories under the star brand products have obtained a number of patent certificates issued by the state, Such as CE certification, IS9001 certification SGS certification, TUV SUD certification, explosion-proof certification and so on. Sensors are used in a wide range of industries Hydraulic system, industrial equipment, refrigeration equipment, intelligent iot, exhaust gas and exhaust gas, indoor and outdoor environment monitoring, soil moisture regulation, chemical and petrochemical, oil and natural gas, torque measurement, engineering machinery, HVAC, water and wastewater, airtight monitoring, industrial gas, planting and breeding, food and beverage industry, pharmaceutical and biotechnology, pulp and concrete, settlement monitoring, etc Yes.

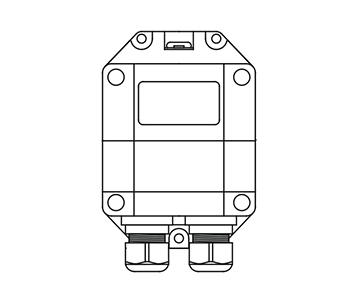

Company Introduction

Star Sensor is a manufacturing high-tech enterprise integrating research and development, production and sales, and has been engaged in the research and development, design and production of various transmitters and related instruments for many years. Xingyi with high quality products, intimate and perfect after-sales, strive to provide users with sensing measurement solutions! The main products are pressure series, liquid level series, temperature series, temperature and humidity series, differential pressure series, soil moisture series, torque series, wireless series and transmitter related accessories.

Accessory products

Service

- Manufacturer: Star sensor has a number of industry production equipment, modern production process. Xingyi's own research and development system, from order to production to optimize the production quality and speed of each link,

- Imported components: satellite sensor selection of high-quality components, imported Germany Hersman plug, long-term stability; Imported silicon wafer, high precision; Imported integrated chip, anti-interference, good stability.

- R&d team: Satellite sensor has a number of sensing technology R&D personnel, committed to product optimization and new product development from beginning to end. A variety of products have obtained a variety of patent certification.

- Product traceability: Each transmitter manufactured by Xingyi has a separate industrial QR code number, and each transmitter sold can trace its parameters and customized content, which is convenient for after-sales and re-customization.

- After-sales service: The satellite sensor has a perfect after-sales testing department, and the installation and use problems encountered in the field use of the product can be well answered by technicians.