Product Description

AS400S is a highly sensitive and low zero drift digital output three-axis acceleration sensor developed by North Micro Sensor, which is suitable for different industrial fields such as vibration monitoring and impact testing. The product adopts digital interface, with RS485/RS232/TTL and other communication modes. The frequency bandwidth of AS400S is DC-100Hz, three-axis measurement. It can work in the temperature range of -40-85℃.

Product parameters

| Technical parameter | Conditions | Index parameter | unit |

| Measuring range | triaxial | ±3.6 | g |

| Resolution | 0.1 | mg | |

| Zero offset | ±3.6g | 0.5 | mg |

| Linear error | 0.02 | % | |

| Noise density | 20 | Pg/Hz | |

| RMS total noise | 0.06 | mg | |

| Response bandwidth | 100 | Hz | |

| Sampling rate | 100 | Hz | |

| Temperature drift | -40 ~125℃ | 2 | mg |

| Null shift | 0.01 | % | |

| Resonance frequency | 1K | Hz | |

| Operating temperature | -125 | ℃ | |

| Class of protection | IP67 | ||

| power | Within 0.5 | W |

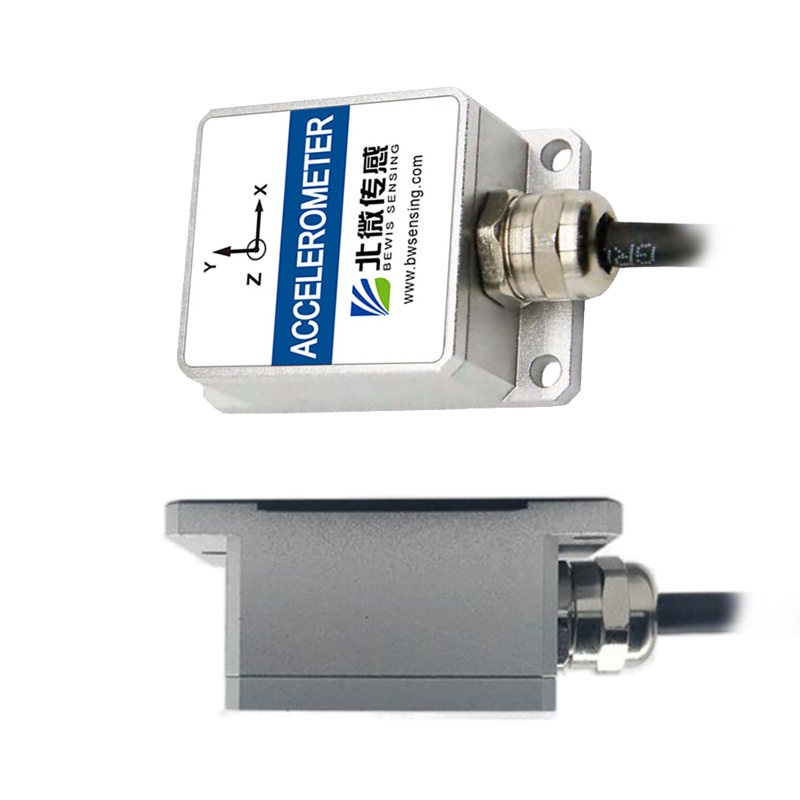

Product Display

High sensitivity:

It can perceptively perceive small acceleration changes, has excellent response ability for weak vibration signal detection, and can detect extremely fine vibration, which is suitable for occasions with high vibration monitoring accuracy.

Low zero drift:

The zero drift is very small, and the stable zero output can be maintained during the long-term monitoring process, so as to ensure the accuracy and reliability of the measurement results, and reduce the measurement error caused by the zero drift

Triaxial measurement:

The acceleration of three axes can be measured at the same time, which can fully and accurately reflect the vibration state of the object in space, provide more abundant data information for complex vibration analysis, and help to better understand the vibration characteristics and motion state of the object.

Miniaturized design:

With compact structure design, small size, light weight, easy to install in a variety of space limited location, less impact on the monitored object, can be widely used in small mechanical equipment, electronic equipment, aerospace components and other occasions with strict size and weight restrictions.

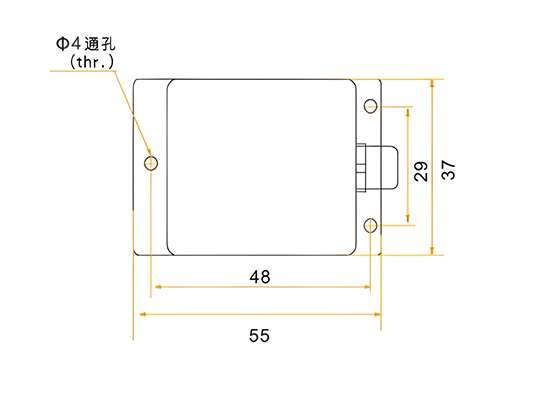

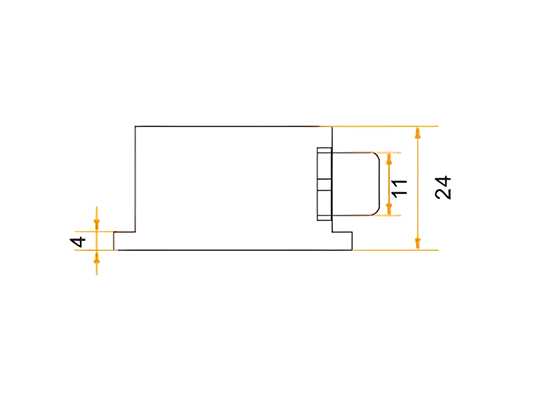

Size & Interface

Quality Control

The quality requirements are extremely strict. In the procurement of raw materials and parts, carefully select suppliers and strictly inspect the factory. In the production process, we operate according to the standardized operation process, set up multiple online detection points for real-time monitoring, and strictly control the production environment. The finished product inspection process, comprehensive performance testing, covering all key indicators, but also reliability testing, including high temperature aging, vibration shock, environmental adaptability, etc. At the same time, build a perfect quality traceability system to ensure high quality and high performance of products, meet the needs of multiple applications and ensure that after-sales can be checked and controllable.

Application Cases

Industrial equipment monitoring: It can be used to monitor the vibration state of various industrial equipment, such as motors, pumps, fans, compressors, machine tools, etc., to grasp the operating status of the equipment in real time, and timely discover potential faults, providing a basis for preventive maintenance of the equipment, reducing equipment maintenance costs, and improving production efficiency

Service

Steady as a rock, the whole guard

First, pre-sale peace of mind planning

A team of professional consultants with rich experience and in-depth insight will analyze product features and advantages for you. According to your unique needs, carefully customized adaptation solutions, provide detailed product descriptions and trial opportunities, to help you clearly plan the application blueprint, start a stable and worry-free journey.

Second, accurate deployment in the sale

Efficient order processing systems ensure fast delivery, and professional technicians perform product installation tests to rigorous standards. Whether it is testing or remote guidance, we strictly control every link, accurate calibration, so that the product is firmly embedded in your business system, smooth operation, seamless connection.

Third, after-sales stability guarantee

Long-term technical support hotline 7×24 hours smooth, senior engineer team quickly respond to consultation and troubleshooting. Regular return visits are combined with in-depth inspection to continuously optimize product performance based on data feedback. During the warranty period, the full range of free maintenance to ensure product stability as before; Beyond the warranty period, still provide intimate and cost-effective maintenance services, with a firm commitment and professional as a escort for product stability, with your business steady forward, no worries.