Product Description

Precision CNC Machining Parts: High-quality components crafted with advanced technology for unmatched accuracy, durability, and optimal performance in diverse applications. Our state-of-the-art equipment and expert engineering ensure consistent quality

Product parameters

| Surface treatment | Polishing, Powder coating, Spraying, Anodising, Zinc Plating Nickel Plating, Chrome Plating and etc . |

| Heat treatment | Annealing, Normalizing, tempering, Quenching,quenching and High temperature tempering ,High frequency heat treatment,Tenifer QPQ and etc. |

| Machine Accuracy :+/-0.005mm~ Inspection Accuracy: +/-0.003mm~ | |

| Equipments | a) CNC Machining Center |

| b) CNC Turning and Milling | |

| c ) Surface grinder , Inside and outside round grinder | |

| d) Electric spark machine | |

| e) CNC Punching Machine | |

| f)Laser cutting machine | |

| g) Precision Cutting Machines | |

| h) Argon Welding Machines and Carbon dioxide protection welding | |

| m)NC Bending Machine | |

| Drawing file format | DXF,DWG,IGS,STP,PDF |

| Preferred Industries | a) Communication Equipments |

| b) Medical Equipments | |

| c) Ship accessories | |

| d) Electronic hardware accessories | |

| e) Mechanical Equipments | |

| f) Other customized Parts | |

| Customized size and spec /OEM available | |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

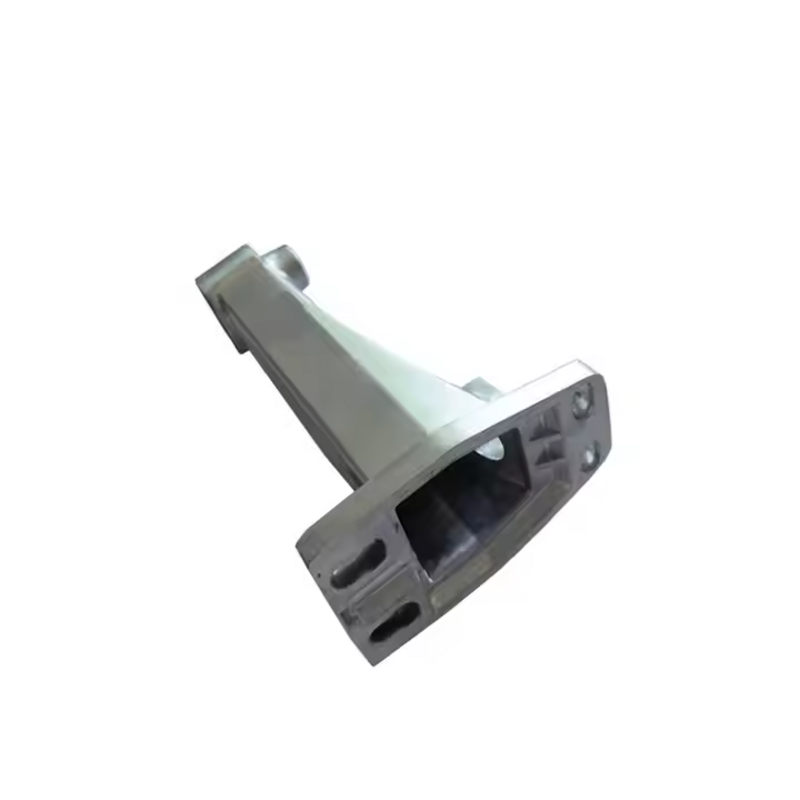

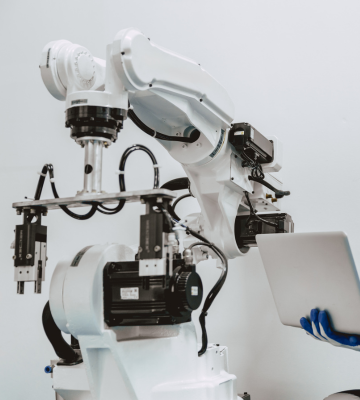

Industrial Robot Arm

Reason: These parts provide structural support for robot arms requiring strength, durability, and lightweight properties for assembly or welding tasks.

Motor Mount

Reason: High precision makes them ideal for securing and supporting motors in applications that demand stability, such as CNC machines or automation equipment.

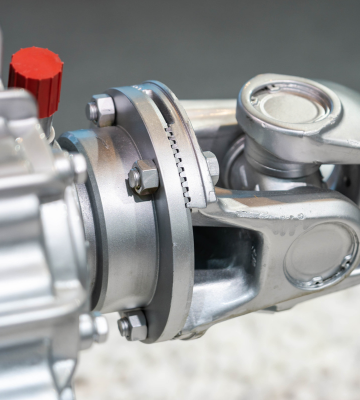

Machine Joint

Reason: Used as a pivot or connection point for machinery due to their design, which supports force and smooth movement effectively.

Material

Stainless Steel

Aluminum Alloy

Quality Control

Quality control for CNC machining parts ensures that each component meets the highest standards of precision and performance. This process involves rigorous inspection of the parts for dimensional accuracy, surface finish, material consistency, and structural integrity. Advanced tools such as coordinate measuring machines (CMM) are used to verify tolerances, while visual checks and functional tests assess the overall quality

Processing capability

The processing capability of CNC machining parts includes the ability to produce highly precise and complex components with tight tolerances. Using advanced CNC machines, parts can be crafted from a wide range of materials, including metals, plastics, and composites, offering flexibility for various applications. The process allows for 3-axis, 4-axis, or even 5-axis machining, enabling the creation of intricate shapes

Additional processes

Additional processes for CNC machining parts enhance the functionality and precision of the components. These processes can include heat treatment to improve hardness and strength, surface finishing techniques such as anodizing, coating, or polishing to enhance durability and appearance, and laser engraving or marking for identification or customization. Furthermore, assembly, welding, and tapping may be incorporated to create more complex