Product Description

A pull-rod cable reel is a device that facilitates moving and storing cables. It is convenient to use the cable in different engineering environments. These devices can effectively prevent cable entanglement and knotting during use and storage, and protect the cable from physical damage to a certain extent. The telescopic rod enables the cable tray to occupy a smaller space when stored, which is easy to store and manage, and improves the space utilization rate.

Product Features

Cable storage and transportation: Ideal storage container for cables. When the cable is not used in the project, the cable is neatly wound on the disk to facilitate inventory management and warehouse storage. Cable trays ensure the integrity and operability of cables when they need to be transported to different construction sites.

For example, in the construction of power projects across regions, cables need to be transported from the manufacturer to the construction site. The cable reel can easily load the rolled cable onto the transport vehicle, and protect the cable from external factors such as friction and collision during transportation.

Flexible transfer of power supply:

The construction site usually needs to flexibly adjust the power supply line according to the location and working scope of the construction equipment. Coil coil can be used as an intermediate switching device, from a fixed distribution box or power source to lead the cable wrapped around it, and then pull the cable to the need for electricity next to the equipment, providing a temporary power connection to the equipment.

For example, in building construction, when workers need to use electric drills, welding machines and other equipment in different floors and different rooms, power transfer can be quickly achieved by moving the cable tray, without the need to lay and remove fixed lines frequently.

Cable protection Angle

Reduce cable physical damage:

The cable is wound on the coil, and its outer layer can play a certain role in protecting the internal cable. During transportation, even when encountering bumps, collisions, etc., the disc body first bears the external force to reduce the possibility of direct damage to the cable.

Moreover, in the process of payoff and collection, because the cable is rotated regularly on the disk, the bending radius of the cable is relatively fixed, which can avoid the internal core breakage or insulation damage caused by excessive bending of the cable (such as the cable bending directly in the sharp corner).

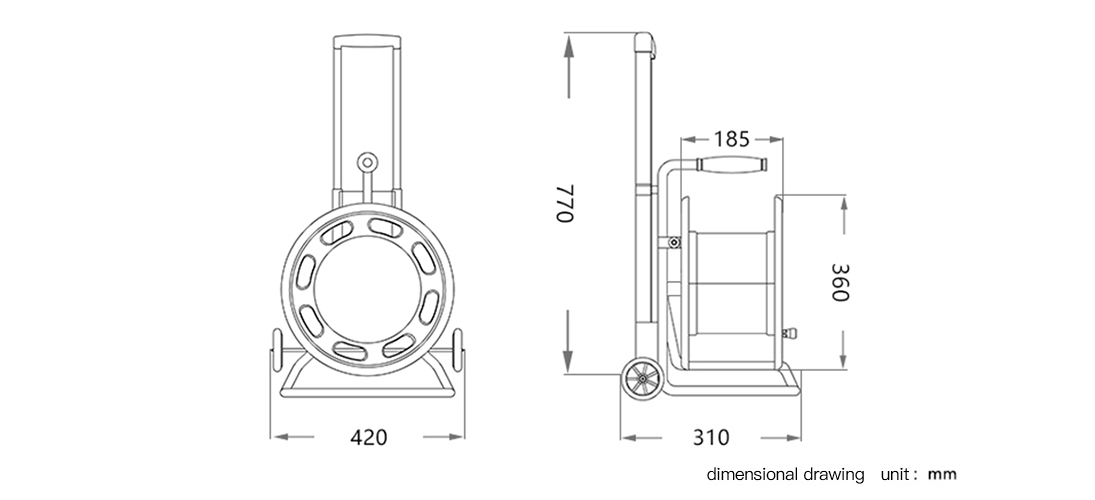

Structure Diagram

Product parameters

| Productmodel | Linespecification*Standardlength | Outputpowerwhenfullyrolled | Poweroutputatfullstretch |

|---|---|---|---|

| ZY-SL36016 | Blankpanel | / | / |

| ZY-SL36016-B13 | 2*1.5mm²x30m | 900W | 2600W |

| ZY-SL36016-B15 | 2*1.5mm²x50m | 900W | 2600W |

| ZY-SL36016-B23 | 2*2.5mm²x30m | 1500W | 4400W |

| ZY-SL36016-B25 | 2*2.5mm²x50m | 1500W | 4400W |

| ZY-SL36016-C13 | 3*1.5mm²x30m | 900W | 2600W |

| ZY-SL36016-C15 | 3*1.5mm²x50m | 900W | 2600W |

| ZY-SL36016-C23 | 3*2.5mm²x30m | 1500W | 4400W |

| ZY-SL36016-C25 | 3*2.5mm²x50m | 1500W | 4400W |

| ZY-SL36016-C43 | 3*4mm²x30m | 2300W | 7000W |

| ZY-SL36016-C45 | 3*4mm²x50m | 2300W | 7000W |

Customer Case

Tianjin Metro Station

State Grid

Tangshan Railway Station

Our Factory

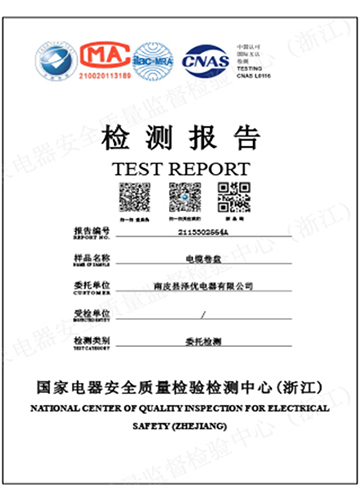

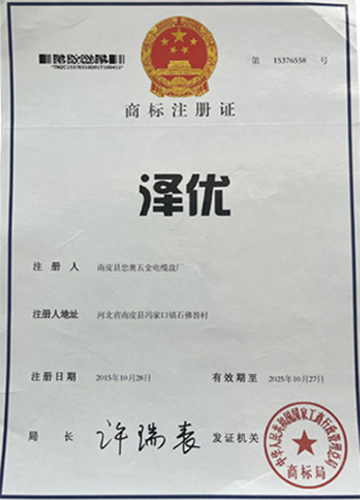

Product Certificate

Service

Manufacturers direct seiko manufacture a tubular cable coil

Good quality Good quality makes good products

Six advantages of strength can not be underestimated 26 years of industry manufacturing experience

Source manufacturers integrity responsible for supporting custom patient service years of experience strict quality control

Pack

Protective material: Wrap a layer of protective material on the surface of the coil, such as plastic film, bubble pad, etc., to prevent scratching and wear during transportation. For electrical coil coils with plugs, sockets and other electrical components, use special protective covers or packaging materials to wrap them well to avoid collision and damage.

Prevent movement and collision: Inside the packaging, use filler such as foam, sponge, etc. to fix the coil coil to prevent movement and collision during transportation. If multiple coils are transported together, place isolation materials between them to avoid friction and collision with each other.

Transport

All modes of transport have measures to ensure the safety of goods, but in practice, the safety performance of different modes of transport is also different. Air transport and railway transport have strict operating norms in the loading and unloading and transportation of goods, and the probability of cargo loss and damage is relatively low. Road transport due to the possibility of complex road conditions, the risk of turbulence and collision of goods is slightly higher, but through reasonable packaging and the choice of reputable transport companies can reduce this risk. Water transport at sea may face risks such as wind and waves, but the safety facilities and cargo fixtures of modern ships can also effectively ensure the safety of goods during transport. Our company will ensure that the product packaging is qualified and firm and choose a strong transportation company to cooperate with the goods safely to the designated place.