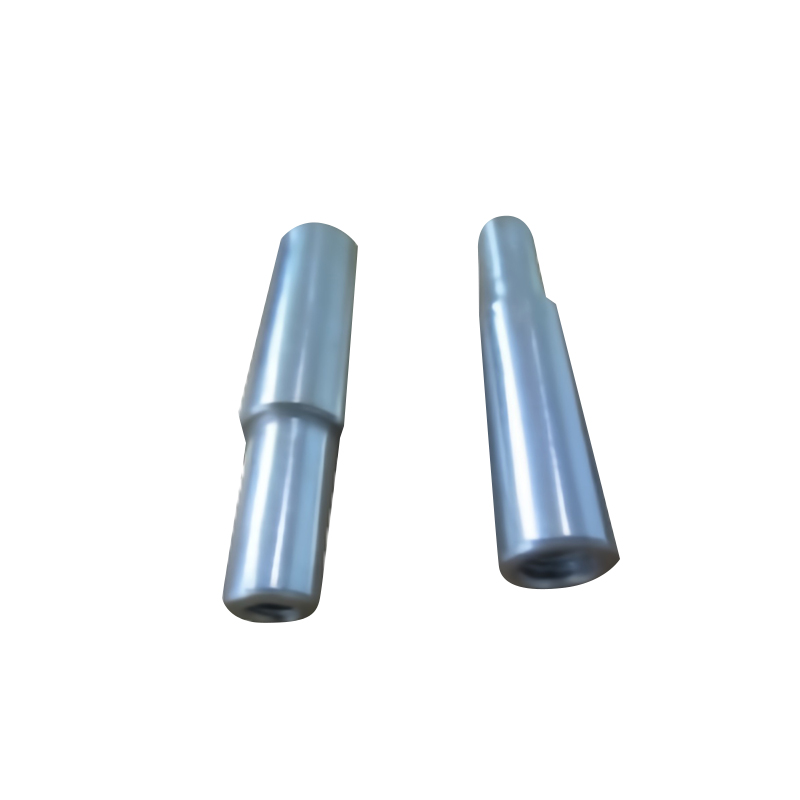

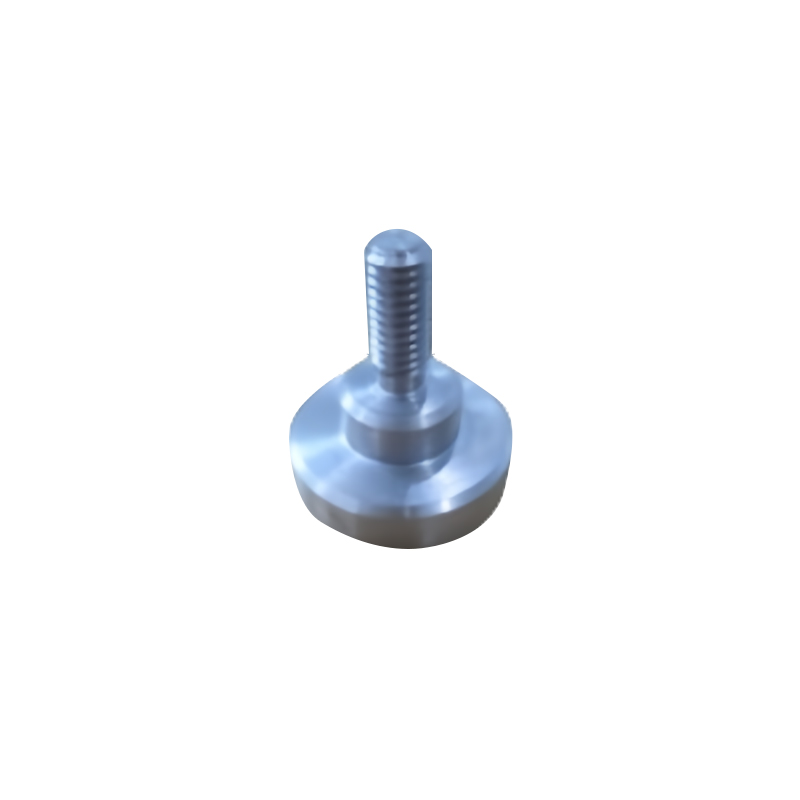

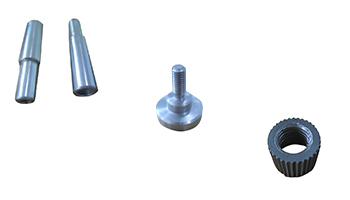

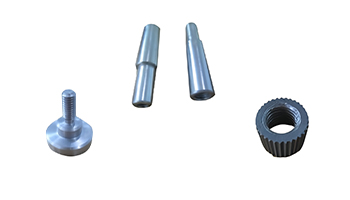

Product Description

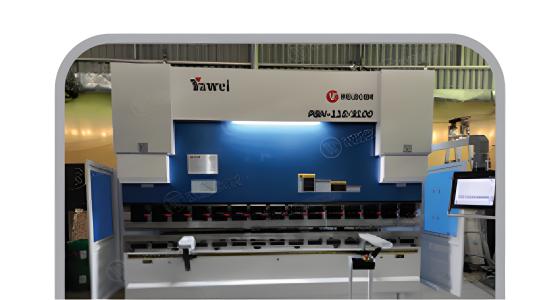

CNC milling machines and lathes CNC,machines that, use laser technology for the mechanical industry such as laser,

cutting machines, laser engraving machines, laser welding.

We constantly improve our work methods and invest in more modem machinery to increasingly serve.

Product parameters

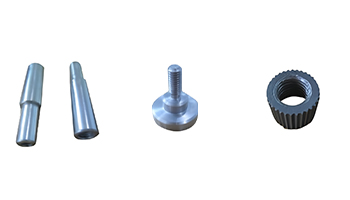

| Material | Steel or Carbide |

| Accuracy | Subject to the drawing details. |

| Delivery time | 14 days |

| Urgent delivery | 7 days |

| Color | Silver |

| Size | Customzied |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

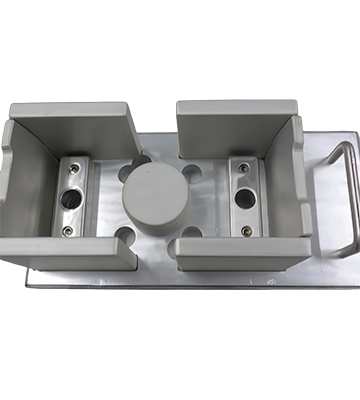

Process Type

Processing module

Structural processing

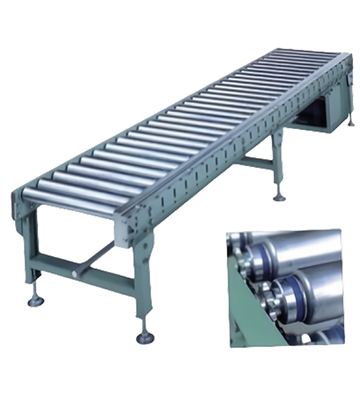

Machine manufacturing

Material

Alloy steel

Brass

Aluminum alloy

Cast iron

Processing capability

LASER ENGRAVING MACHINE

The laser engraving machine shows excellent processing ability. Its high-precision laser beam is precisely focused and can be delicately carved on a variety of materials. Whether it is a complex pattern or a delicate motif, it can produce it stably. It has low noise during operation, excellent heat dissipation, continuous operation without lag and stable attitude to ensure that every processing is accurate and the task is completed efficiently.

Additional processes

CNC LATHES MACHINE

It relies on advanced CNC systems to precisely plan tool paths and easily handle all types of metal processing. Turning, boring, and threading are all done smoothly. During operation, the machine tool is as stable as a rock, with minimal vibration to ensure accuracy, silent heat dissipation, low-noise operation, and continuous production of high-precision parts, empowering industrial production.