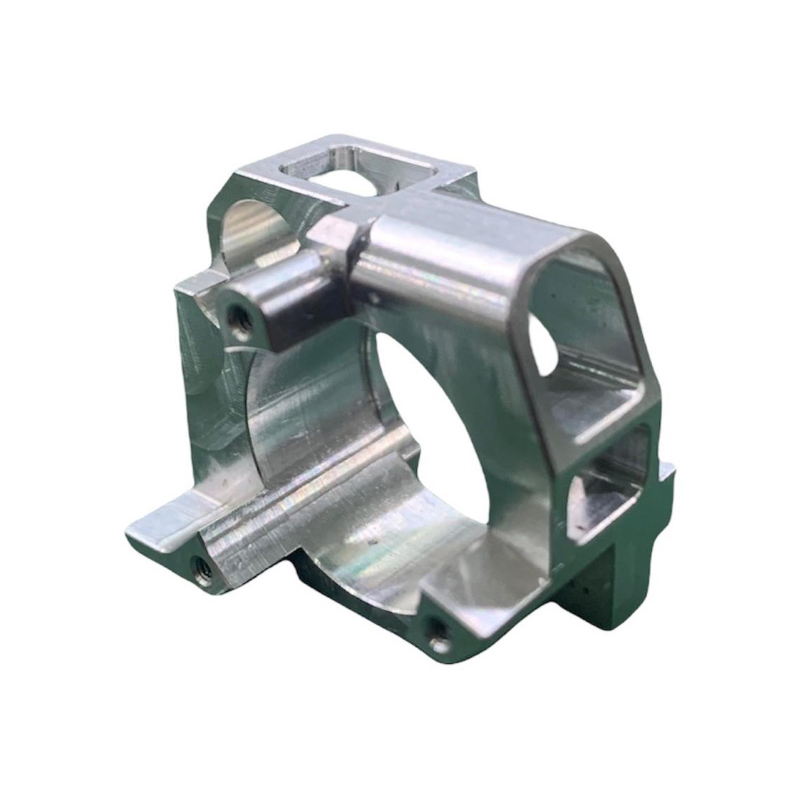

Product Description

We specialize in OEM CNC machining services and are committed to creating high-precision CNC machined parts. With advanced CNC equipment and sophisticated machining technology, we can strictly control every production detail to ensure that the part size is accurate and the tolerance is controlled within a very small range. Regardless of the complex design and customization requirements, we can rely on the rich experience of our professional technical team to efficiently customize for you and provide high-quality, high-precision parts processing solutions to meet your diverse needs in different fields.

Product parameters

| Size | Custom Drawing |

| Machinable materials | Stainless steel, aluminum alloy, copper alloy, titanium, etc. |

| Certification | ISO 9001:2015 |

| Process | CNC Milling / CNC Turning / CNC Machining, etc. |

| Quality control | 100% Inspection Before Shipment |

Custom Process

1.Requirements communication

2.Design drawings

3.Procurement of materials

4.Processing and Manufacturing

5.Surface treatment

6.Assembly and debugging

7.Inspection and packaging

8.Delivery and After-sales

Process Type

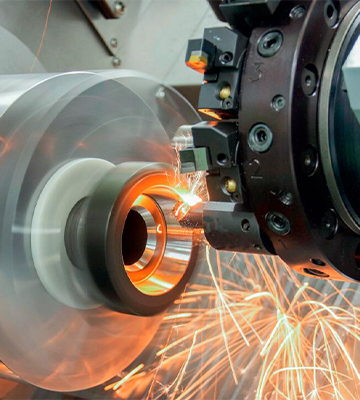

Turning process

On a lathe, by rotating the workpiece and moving the tool to cut, it can process rotating structures such as cylinders, cones, and threads. It is widely used in mechanical manufacturing and other fields, and can accurately shape the shapes of various shafts, disks and other parts.

Heat treatment process

Heating, heat preservation and cooling of materials to change their internal structure, achieving effects such as quenching to increase hardness, tempering to eliminate stress, normalizing to refine grains, annealing to improve plasticity, etc., greatly improving the overall performance of parts.

Wire cutting process

Using a moving thin metal wire as an electrode, the electric spark discharge generated by pulse voltage is used to melt or vaporize the conductive material, thereby completing the cutting of the workpiece. It is often used to process molds and parts of complex shapes.

Material

Aluminum Alloy

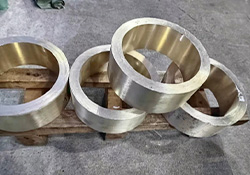

Copper Alloy

Carbon Steel

Titanium

Quality Control

From strict screening of raw materials at the time of storage, to real-time monitoring and parameter calibration of high-precision equipment during processing, to multiple rounds and full-dimensional testing of finished products, our precision machining manufacturers conduct quality control with strict standards at every stage. With a professional quality inspection team and advanced testing equipment, we ensure that every delivered product meets the requirements of high precision and high performance, providing solid guarantee for customers' projects.

Processing capability

At Microvit, we combine cutting-edge technology and experienced CNC programming expertise to provide full-service CNC machining for the High-Mix Low-Volume production of complex, three-dimensional metal components and parts. With more than 35 CNC machining centers and day-and-night operation, we can swiftly and effectively produce the machined components, with remarkable quality and high reproducibility from the first to the last piece.

Additional processes

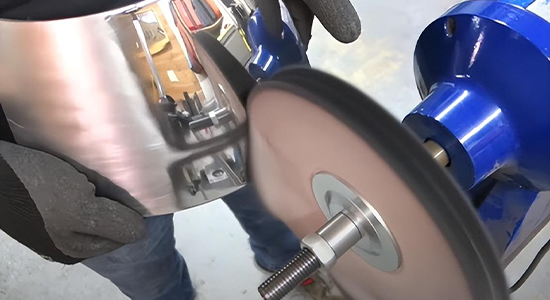

The polishing process uses mechanical, chemical or electrochemical methods to use polishing tools and abrasive particles to perform micro-cutting or corrosion on the surface of the workpiece to reduce its surface roughness and improve surface finish and flatness. It can make the workpiece appear shiny and improve its corrosion resistance, wear resistance and other properties. It is widely used in the processing of various materials such as metal, plastic, glass, etc.