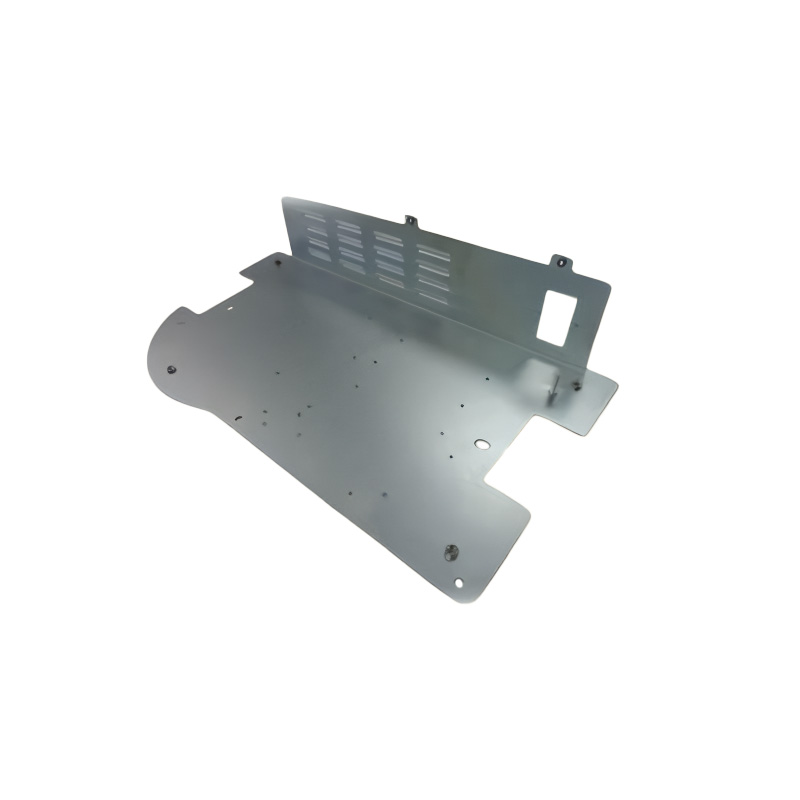

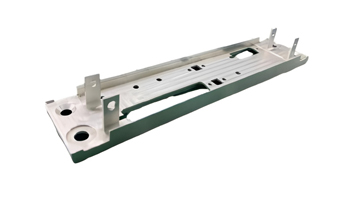

Product Description

We provide professional CNC turning services and focus on customizing various precision machined parts. With advanced CNC equipment and exquisite craftsmanship, we strictly control the precision and can meet diverse needs from tiny parts to complex components. We ensure high-quality delivery and provide reliable and accurate parts solutions for your project.

Product parameters

| Certification | ISO 9001:2015 |

| Material | Stainless steel, aluminum alloy, carbon steel, copper alloy, iron, titanium |

| Processing Technology | CNC Multi-Axis Milling、Precision Turning、Rotary CNC、EDM、Wire Cut |

Custom Process

1.Requirements communication

2.Design drawings

3.Procurement of materials

4.Processing and Manufacturing

5.Surface treatment

6.Assembly and debugging

7.Inspection and packaging

8.Delivery and After-sales

Process Type

Laser cutting process

Laser cutting uses a high-energy-density laser beam to rapidly melt and vaporize materials, and then blows away the melt with high-pressure gas to achieve precise cutting. It has the advantages of high precision, high speed, and small heat-affected zone, and can process a variety of materials.

Turning process

On a lathe, by rotating the workpiece and moving the tool to cut, it can process rotating structures such as cylinders, cones, and threads. It is widely used in mechanical manufacturing and other fields, and can accurately shape the shapes of various shafts, disks and other parts.

Heat treatment process

Heating, heat preservation and cooling of materials to change their internal structure, achieving effects such as quenching to increase hardness, tempering to eliminate stress, normalizing to refine grains, annealing to improve plasticity, etc., greatly improving the overall performance of parts.

Material

Aluminum Alloy

Copper Alloy

Titanium

Carbon Steel

Quality Control

From strict screening of raw materials at the time of storage, to real-time monitoring and parameter calibration of high-precision equipment during processing, to multiple rounds and full-dimensional testing of finished products, our precision machining manufacturers conduct quality control with strict standards at every stage. With a professional quality inspection team and advanced testing equipment, we ensure that every delivered product meets the requirements of high precision and high performance, providing solid guarantee for customers' projects.

Processing capability

Precision Machining

High Standards of Product and Promptness in Service.

1. CNC Multi-Axis Milling

2. Precision Turning

3. Rotary CNC

4. EDM

5. Wire Cut

*Tolerance ±5µm

Additional processes

Electroplating process

Electroplating is a process of depositing a layer of metal or alloy on the surface of metal or other materials by electrochemical methods. The principle is to use the workpiece to be plated as the cathode in a solution containing metal ions, and use direct current to reduce and deposit the metal ions on the surface of the workpiece to form a uniform and dense coating.