Product Description

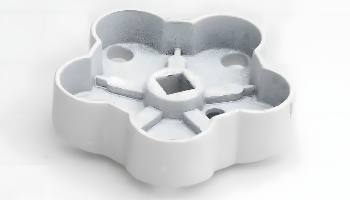

OEM aluminum alloy casting products are parts made from aluminum alloys through a casting process, offering high strength and durability. These products are suitable for use in various industries such as automotive, electronics, or machinery. Aluminum alloys are lightweight and resistant to corrosion, making them ideal for demanding applications. OEM (Original Equipment Manufacturer) production allows for precise and customized manufacturing based on customer requirements. Advanced casting technologies are used to ensure high-quality products with excellent performance.

Product parameters

| List | Details |

|---|---|

| Brand Name | Professional Manufacturer Aluminum Die Casting |

| Application | die casting |

| Material | aluminum ,zinc Etc |

| Metal parts weight | 1-10kg |

| Certification | ISO9001:2008 |

| Surface treatment | custom |

| Application | Industrial Equipment |

| Process | Casting +Machining(if Need)+surface Treatment |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

Sheet Metal Fabrication

The process of transforming flat sheets of metal into various shapes and structures through techniques such as cutting, bending, punching, and welding. This method is widely used in the manufacturing of components for industries like automotive, construction, aerospace, and electronics. By utilizing machines like laser cutters, CNC presses, and brake presses

Surface Treatment

Refers to a variety of processes used to modify the surface of materials, particularly metals, to enhance their properties and performance. These processes are designed to improve qualities such as corrosion resistance, wear resistance, hardness, adhesion, and aesthetic appeal. Common surface treatments include plating (e.g., zinc, nickel, or chrome), anodizing, powder coating, painting, polishing, and laser surface hardening.

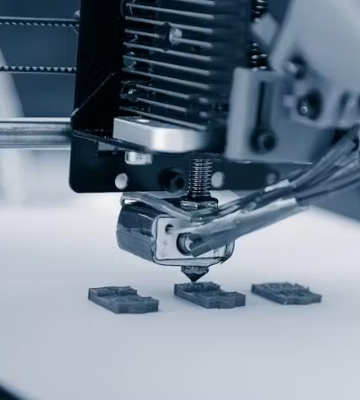

3D CNC printing

is a technology that uses CNC machines to create three-dimensional parts from various materials such as metal, plastic, or wood. In this process, the movement of the machine is controlled by computer programs to achieve the desired shape. 3D CNC printing can be used to produce high-precision parts, such as machine components, medical devices, or even structures for research and development. This technology helps improve manufacturing accuracy and reduces the steps involved in assembling the final product.

Material

Stainless steel

Aluminum

Titanium

Brass

Additional processes

The processing capabilities of OEM aluminum alloy casting include the design and production of high-precision parts based on customer requirements. Using advanced casting technology, complex-shaped parts can be efficiently created. Materials and processes can be customized to suit various conditions, such as corrosion resistance or high load-bearing requirements. Additionally, further processing techniques, such as milling or drilling, can be applied to enhance the precision and quality of the products, ensuring they meet industry standards.