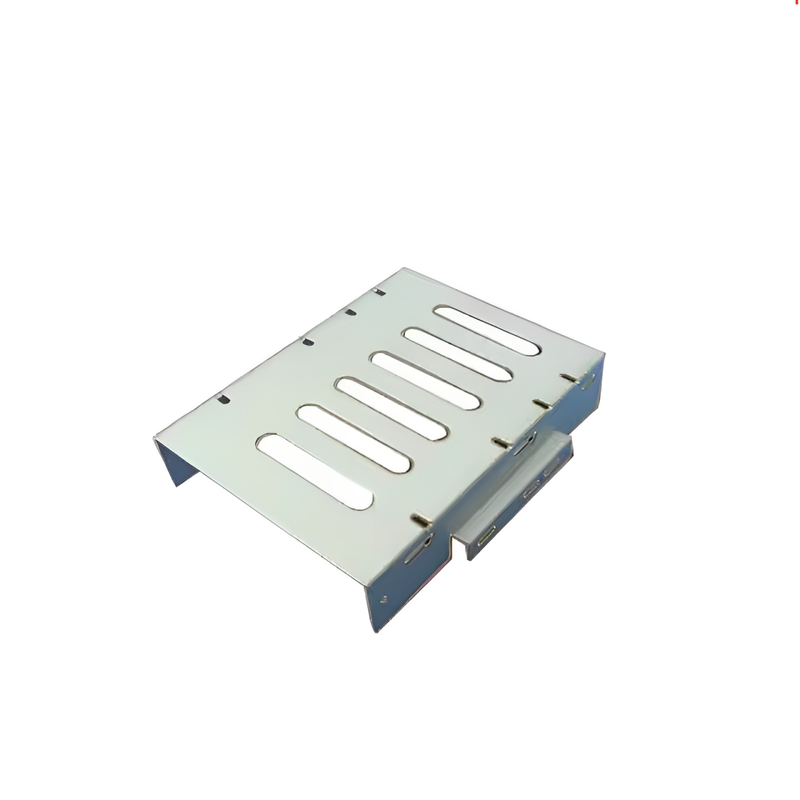

Product Description

We accept metal stamping and assembly work according to the design, utilizing high-standard technology and ensuring precision, durability, and consistency throughout the production process. Our skilled team leverages advanced machinery and techniques to produce high-quality components that meet the most stringent specifications. From the initial design phase to final assembly, we prioritize quality control and continuous improvement, guaranteeing that every part performs reliably in its intended application.

Product parameters

| Dimensions | customized |

| Material | SPCC,SECC,SGCC,stainless steel,brass,aluminum steel,etc. |

| Surface treatment | plating,anodized,power coating,polished,painting, gilding. |

| Packaging | cardboard, k=k carton |

| Sample time | 7 day |

| Drawing format | PDF, STP,STEP,DWG, CAD |

| Process | staming, punching, bending,wire cutting,laser cut,welding,riveting. |

| Payment | T/T50% deposit, 50% balance before shipment |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Automotive Body Components

Reason: These parts are used in vehicle manufacturing for components like door panels, fenders, and chassis parts. The stamping process offers high precision, durability, and cost-effectiveness, ensuring that the parts meet safety and performance standards while being lightweight and strong.

Appliance Frames

Reason: Sheet metal stamping is used for appliance frames, such as those in refrigerators, washing machines, and ovens. The strength, durability, and flexibility of stamped sheet metal allow for the creation of complex shapes that can withstand high heat and heavy usage in everyday appliances

Industrial Equipment Parts

Reason: Custom stamped sheet metal is used in parts for industrial equipment, such as machine enclosures, brackets, and structural components. The stamping process allows for high-volume production of strong and accurate parts, making them suitable for machinery that requires durability and precision under heavy loads

Material

Aluminum Alloy

Iron

Stainless Steel

Quality Control

Our Quality Control for Precision Metal Stamping & Welding Solutions is a comprehensive process that ensures every product meets the highest standards of accuracy and performance. We utilize advanced inspection tools and techniques throughout the production cycle, from initial material selection to final product testing. Each part undergoes rigorous checks for dimensional accuracy, surface quality, and structural integrity to meet customer specifications and industry standards.

Processing capability

Our processing capability for Precision Metal Stamping & Welding Solutions combines cutting-edge technology with expert craftsmanship to deliver high-quality, custom solutions. We specialize in metal stamping, deep drawing, and complex welding processes, enabling us to produce parts with tight tolerances and intricate designs. Our state-of-the-art equipment, including CNC machines and automated stamping presses, ensures precision and efficiency in both small and large production runs. With expertise in working with a variety of metals and alloys, we are capable of handling projects that require durability, accuracy, and excellent structural integrity.

Additional processes

In addition to our core metal stamping and welding services, we offer a range of supplementary processes to further enhance the functionality and quality of the parts we produce. These include surface treatments such as coating, anodizing, and plating for improved corrosion resistance and aesthetic appeal. We also provide custom assembly services, ensuring seamless integration of stamped and welded components into complete assemblies.