Product Description

A Wire Harness Cable Assembly is a pre-assembled set of wires, connectors, and terminals designed to transmit electrical power or signals efficiently. It is used to organize and connect multiple electrical components in various applications, such as automotive, industrial, and consumer electronics. The assembly is custom-built to ensure compatibility with specific devices or systems, reducing installation time and improving reliability. Made from high-quality materials, it ensures durability, safety, and optimal performance. Wire harnesses can be tailored with different wire types, lengths, and connectors based on customer requirements. They are designed for easy integration and to withstand harsh environments.

Product parameters

| List | Details |

|---|---|

| Product | OEM ODM Automotive Wire |

| Application | Automobile |

| Color | TS5510 |

| Standard of Wire Harness | OEM ODM Accept |

| Wire Length | Customized |

| Wire Gauge | Customized |

| Pins | According to your requirement |

| Certification | ISO9001,ISO14001,IATF16949 |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

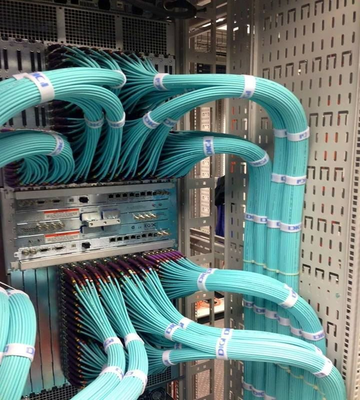

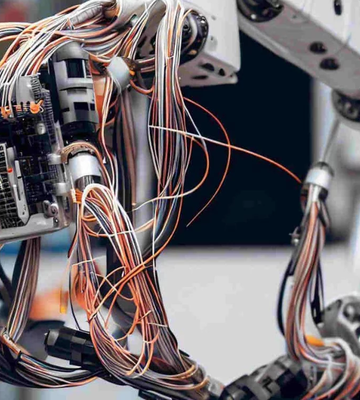

Process Type

Machining Part Wiring

Robot Part Wiring

Electrical Part Wiring

Material

Copper

Nickel

Aluminum

Quality Control

The QC (Quality Control) of a Wire Harness Cable Assembly ensures the assembly meets stringent standards for performance, safety, and reliability. Each harness undergoes visual inspections for wire routing, connector placements, and secure terminations. Electrical testing is performed to check continuity and correct signal transmission. Insulation resistance and durability tests ensure the harness can withstand various environmental conditions. All materials used are verified for compliance with industry specifications. Final checks include measuring wire lengths, verifying connector compatibility, and ensuring the product meets customer-specific requirements before shipment.

Processing capability

The wire harness undergoes quality control inspections at multiple stages, including visual inspections, electrical testing, and stress testing for mechanical strength and reliability. Environmental testing ensures that the assembly can endure extreme conditions such as temperature fluctuations, vibrations, and moisture exposure.

Lastly, the wire harness is packaged, labeled, and prepared for shipment, ensuring that it is ready for seamless integration into the intended system. This comprehensive process ensures the production of highly reliable and customized wire harness assemblies for diverse industries, including automotive, aerospace, and industrial applications.