Product Description

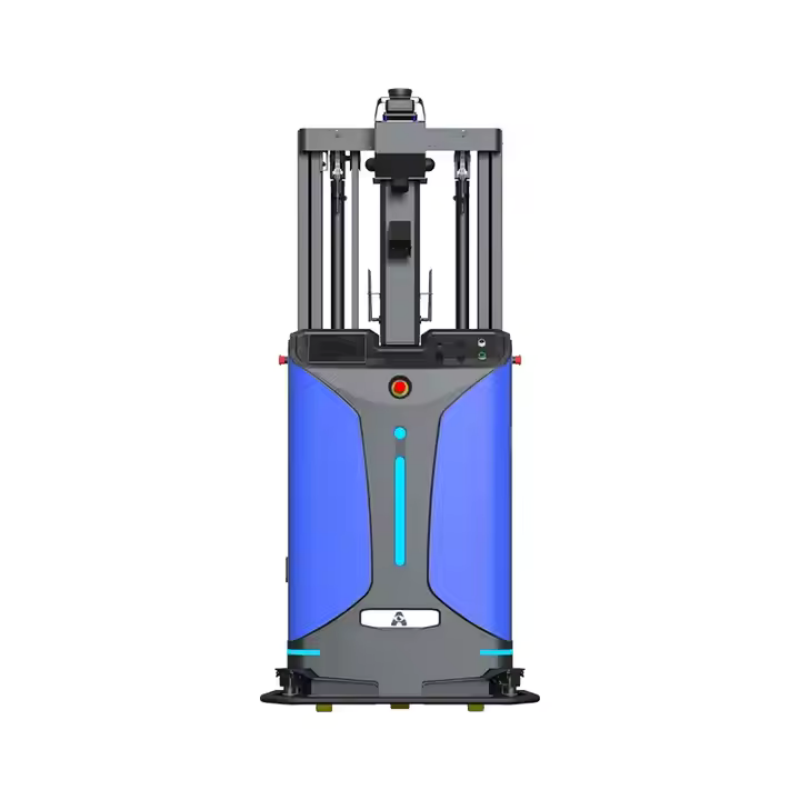

AUTOMATE GUIDED VEHICLE

APRobotics's AGV applied modern technologies, mainly used in smart factories and warehouses. This is a smart and safe solution that helps businesses optimize resources, costs and improve production efficiency.

By applying the world's leading technologies, we are confident that this is one of the most advanced AGV in Vietnam which can move in both directions (forward and backward). With a team of experienced engineers, we are always ready to thoroughly solve the problems that customers encounter and promise to bring new, optimal and wonderful experiences with these AGVs and solutions.

Product Features

Adaptable feature exchange

AGV consists of two parts: Smart AGV and Smart tools. Smart AGV is the base that can be moved flexibly according to the digital map and Smart tool is the upper function that can be changed arbitrarily based on usage requirements. These two parts are mechanically linked by a quick-release system, combining functions with central management software. Therefore, it is possible to flexibly use many features of the robot, to improve efficiency and save investment.

AGV Operation control

AGV is equipped with a variety of sensors such as laser radar and ultrasonic sensors, which can fully perceive the surrounding environment. When an object appears on the driving path, the laser radar quickly captures the outline of the object and the ultrasonic sensor measures the distance. The two work together to trigger the AGV to slow down and stop immediately if necessary to ensure safe operation.

Dynamic motion controls

The AGV robot uses an advanced dynamic motion control system to precisely control the motor output power to achieve smooth acceleration. When braking, the efficient braking device responds quickly to ensure safe parking within a short distance. In the face of large turning radius, the system intelligently adjusts the speed of each wheel to easily handle complex tasks.

Application Cases

As a manufacturer, APRobotics helps our customers improve efficiency and reduce costs by fully meeting the needs of mass customization through robots in automatic transportation, traction and lifting in factories and warehouses.

Survey, consult, supply and deploy optimized robots in customers' existing spaces and facilities;

Integrate APRobotics robot solutions with customers' existing management software systems;

Upgrade/update AGV/AMR robots to meet new customer needs in the future;

Provide manufacturer's fast maintenance and warranty services to minimize customers' production downtime.

Technical Parameter

Size | 1.1m x 0.64m x 0.283m |

Max Speed | 0.7m/s |

Max Payload | 250kg |

Battery Voltage | 24VDC |

Charging Time | 4hours |

Connect | Wifi/Ethernet |

FAQ

What mode of transportation do you usually use?

We mainly use three modes of transportation: sea transportation, air transportation and express delivery. For large quantities of goods, it is generally recommended to choose sea transportation, which is relatively cheap; for urgent orders or small quantities of high-value goods, air transportation or express delivery will be more suitable.

How long does it take from ordering to delivery?

In general, the delivery time of conventional products is about 30 days after the order is placed. If it is a customized product, the delivery time may be extended to 50 days. The specific time will be determined according to the specific circumstances of the order.

How long is the warranty period of the product?

The warranty period of our products is generally 1 year, calculated from the date of qualified acceptance of the goods. During the warranty period, if there is a quality problem with the product, we will provide free repair or replacement service.

If there is a problem with the product during use, how to carry out after-sales repair?

If there is a problem with the product, you can first contact our customer service staff and provide detailed information and problem description of the product. We will arrange professional technicians for remote guidance.