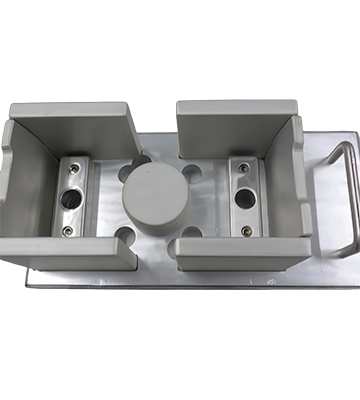

Product Description

Carefully carve each non-standard metal CNC processing accessory, from high-quality metal selection to delicate processing, to ensure the perfect combination of high precision and durability.

Product parameters

Material | Steel or Carbide |

Accuracy | Subject to the drawing details. |

Delivery time | 14 days |

Urgent delivery | 7 days |

Color | Silver |

Size | Customzied |

Tolerance | 0.02 to 0.10 mm |

Raw material | Aluminum, Titanium, Copper, Stainless Steel, Steel Alloy, Inconel, cast iron |

Process | CNC Machining Milling Turning |

Service | One Stop Service. Machining-assembly |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Process Type

Structural processing

Processing module

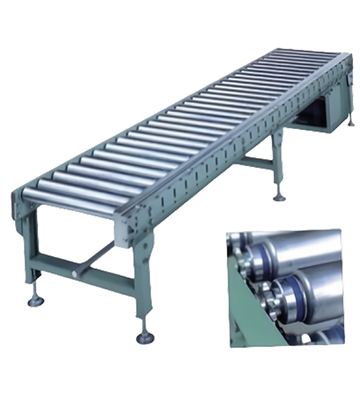

Machine manufacturing

Material

Brass

Aluminum alloy

Alloy steel

Cast iron

Quality Control

Gear processing machine. It can process gears with high precision and has an advanced CNC system that can accurately control processing parameters. It is suitable for industries such as automobiles and aviation that require high gear precision, effectively ensuring gear processing quality and transmission performance.

Processing capability

Vertical machining center. It has three-axis linkage capability and can perform milling, drilling, boring and other processing on a variety of metals and some non-metallic materials. The worktable can carry a certain weight of workpieces, has a high maximum speed, and has precise positioning accuracy and repeatability, making it suitable for single or small-batch production of small and complex parts

Additional processes

The equipment processes the workpiece, and additional processes may include clamping and positioning to accurately fix the workpiece on the workbench; real-time monitoring of the processing process, checking the processing accuracy and progress through the equipment system; after completing the initial processing, there may be processes such as deburring and surface cleaning to ensure that the workpiece meets quality standards.