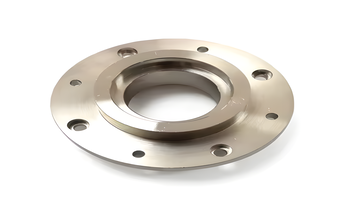

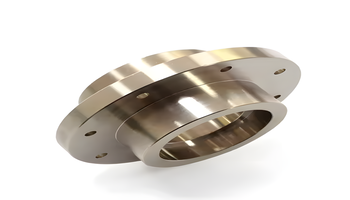

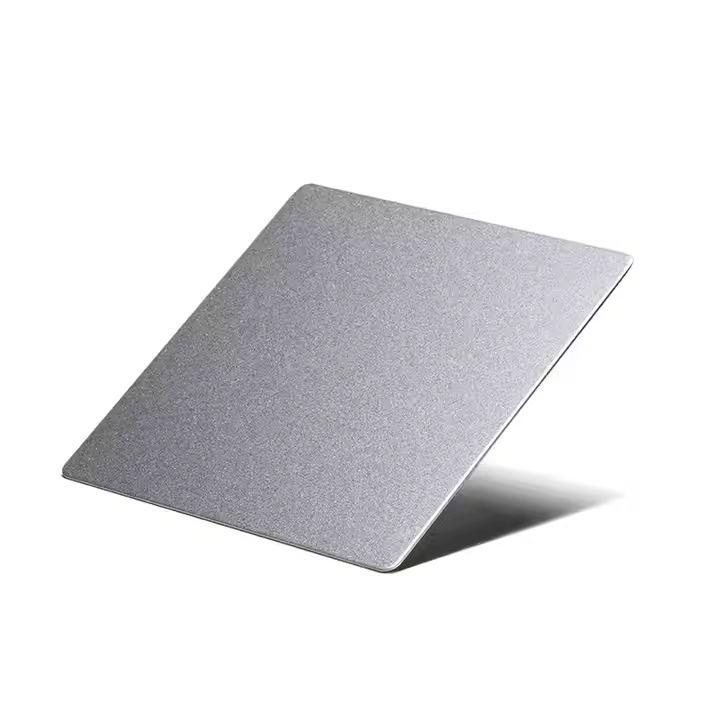

Product Description

Our titanium CNC machining service specializes in high-precision milling and turning of titanium parts. We utilize advanced CNC technology to achieve tight tolerances and complex geometries. Titanium parts are known for their strength, durability, and resistance to corrosion. We offer both prototype and production runs, ensuring fast turnaround times. Our team delivers high-quality, custom titanium parts for various industries. From aerospace to medical, we provide reliable and precise solutions for all your titanium machining needs.

Product parameters

| List | Details |

| Brand name | cnc milling lathe parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, plastic |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Process | cnc machining |

| Service | OEM&ODM,CNC machining as per customers' request |

| QC control | 100% inspection on critical dimensions |

| Tolerance | +/-0.01-+/-0.05mm |

| Material | steel |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

Process Type

Honing

is a precision machining process used to improve the surface finish and dimensional accuracy of parts. It involves a honing tool with abrasive stones that rotate and reciprocate on the workpiece. Typically, it is used for cylindrical surfaces such as engine bores. Honing removes small amounts of material to achieve smoother surfaces and tighter tolerances. It is commonly applied in industries like automotive and aerospace. The process also enhances the part's durability and wear resistance.

Laser cutting

is a technology that uses a high-powered laser to cut through materials like metal, plastic, and wood. The laser beam melts or vaporizes the material along a precise path. It allows for highly accurate cuts with minimal thermal distortion. This process is used in industries such as automotive, aerospace, and manufacturing. Laser cutting is fast, efficient, and produces clean edges. It can handle complex shapes and intricate designs with ease.

Milling

is a machining process that uses rotary cutters to remove material from a workpiece. The workpiece is fed into the cutter, which rotates at high speeds to shape it into desired forms. It can produce a variety of features like holes, slots, and complex contours. Milling is used on materials like metal, plastic, and wood. There are different types of milling, including horizontal and vertical, depending on the setup. This process is widely used in industries like manufacturing, automotive, and aerospace for precision parts.

Material

Sliver

Brass

Copper

Quality Control

Processing capability