Product Description

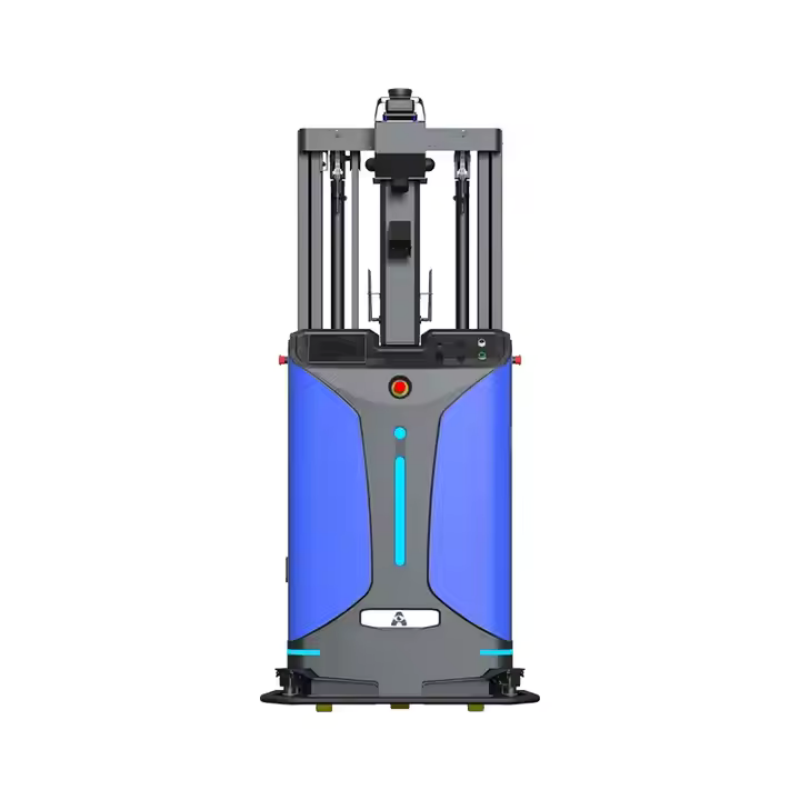

Driven by top-level SLAM technology, our systems achieve positioning and navigation accuracy within ± 2mm, maintaining excellent consistency. We provide comprehensive resources for smart manufacturing and efficient internal logistics solutions. Including controllers, AMR (autonomous mobile robots), logistics digitalization and visualization AI solutions. Our goal is to enable system integrators to develop comprehensive, ready-to-deploy internal logistics and automation solutions.

Product Features

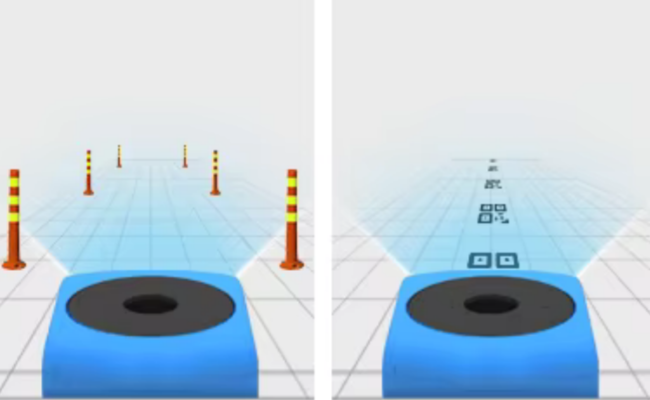

Laser reflector navigation is based on SLAM technology, which achieves millimeter-level positioning by scanning reflective plates with laser radar. It is suitable for structured environments such as industrial warehouses. QR code navigation uses visual recognition technology to achieve centimeter-level positioning by reading preset QR codes. It is highly flexible and suitable for dynamic scenes. Both support autonomous path planning to meet the needs of different scenes.

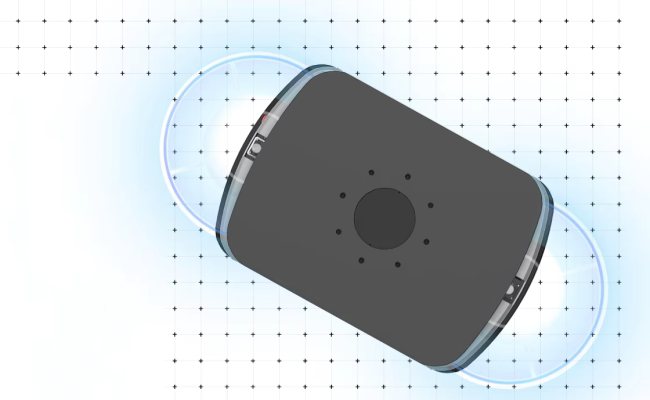

The robot supports multi-modal navigation technologies such as laser reflectors and visual recognition, and combines SLAM algorithms with multi-sensor fusion to achieve ±5mm repeatability. The system can dynamically switch navigation modes to adapt to complex environments, ensuring accurate path planning and efficient operation in scenarios such as industrial handling and warehousing sorting.

Application Cases

AGV chassis are widely used in manufacturing, logistics warehousing, medical, electronics, automobile and other fields to realize automation tasks such as material handling, production line distribution, drug transportation, electronic component handling, automobile assembly, etc., with the characteristics of high efficiency, precision and flexibility.

Technical Parameter

Navigation method | Laser SLAM | Drive mode | Two-wheel differential |

Weight (with battery) | 150kg | Load capacity | 300kg |

Rotation diameter | 910mm | Jacking platform dimensions | 760mm*545mm |

Minimum passable width | 640mm | Navigation angle accuracy | ±0.5 |

Battery life | 8h | Charging time (10-80%) | ≤1 |

Charging method | Manual/Automatic | Shell color | Customized |

FAQ

What is your MOQ?

MOQ: depends on the product, 2 pcs for sample order is acceptable.

What is your delivery time?

Stock goods can be shipped within 7 working days. Bulk order, 15-90 working days depends on your quantity.

Is OEM & ODM acceptable?

Yes, we welcome OEM and ODM orders. Please tell me your ideas or provide us your drawings.